Understanding the Importance of Natural Gas Safety Valves

Understanding the Importance of Natural Gas Safety Valves

In industrial settings, pressure reducers play a vital role in manufacturing processes where gas is used as a raw material or energy source. In these applications, precise pressure regulation can significantly impact efficiency and product quality. They are also crucial in laboratories, where controlled environments are necessary for experiments.

One of the key advantages of gas boosters is their ability to improve system efficiency. By maintaining optimal pressure levels throughout the gas distribution network, these devices minimize energy losses, ensuring that more of the supplied energy reaches end-users. This efficiency not only lowers operational costs but also reduces the environmental impact of gas consumption, as less energy waste translates into lower carbon emissions.

The benefits of utilizing filter separators are manifold. They improve product quality, enhance operational efficiency, and reduce equipment downtime by preventing contamination. Additionally, they contribute to environmental protection efforts through the proper handling of waste products.

Despite advancements in technology and materials, the management of gas pressure vessels continues to present challenges. For instance, overpressure situations can lead to dangerous scenarios, including explosions. Innovations in design, such as the development of rupture disks and safety valves, help mitigate these risks. Furthermore, research into alternative materials and designs aims to create lighter, yet equally strong, vessels, which could lead to increased efficiency and reduced material costs.

4. Shuttle Valves Used in applications where two sources of air are available, shuttle valves ensure that the airflow comes from a predetermined source, providing redundancy and reliability in systems.

- Functionality Test the operation of manual valves regularly to ensure they open and close smoothly. For automatic valves, inspection should include checking the sensors and control mechanisms to ensure they operate reliably.

Another significant benefit is their environmental impact. As electric vehicles become more common, the reliance on electric heating solutions supports renewable energy sources. By using electricity from sustainable sources, we can reduce carbon footprints and transition toward greener technologies.

A part of the National Institutes of Health, the National Heart, Lung, and Blood Institute is dedicated to conducting research and providing education on heart and vascular diseases, including hypertension. The NHLBI promotes initiatives that explore the causes of high blood pressure and develop effective treatment methods. Their HEART initiative, for instance, aims to educate the public about hypertension and encourage screening, especially among at-risk populations. The NHLBI also supports clinical trials and research studies to determine best practices for blood pressure management.

Tourists also flock to the city gate station, eager to explore all that the city has to offer

. With its convenient location and easy accessibility, the station serves as a gateway for tourists to discover the city's many attractions, from historic landmarks to cultural hotspots.

Designing a pressure vessel requires a deep understanding of engineering principles and material science. Key factors to consider include

Shut-off valves come in several types, with each designed for distinct applications. The most common types include

- Compact Design Many heat exchangers can fit into tight spaces, making them suitable for various installations without requiring extensive modifications.

1. Healthcare In medical facilities, regulators are essential for controlling the pressure of oxygen and other gases supplied to patients. Proper regulation ensures that patients receive the correct dosage of gases for their respiratory needs.

2. Automation In modern manufacturing, automation is critical. Air control valves enable automated machinery to perform tasks without human intervention, increasing productivity and reducing the likelihood of error.

The Role and Importance of Natural Gas Distribution Stations

Types of Natural Gas Pressure Reducers

Modern gas pressure reducing stations often integrate smart technologies, enabling remote monitoring and control. By leveraging the Internet of Things (IoT), operators can monitor multiple stations from a central location, improving response times to potential issues and optimizing operational efficiency.

Moreover, smart organizers utilize advanced analytics to help users identify their productivity patterns. By analyzing data on when individuals are most productive, the organizer can suggest ideal times for tackling challenging tasks or highlight periods when breaks are necessary. This data-driven approach not only fosters better time management but also contributes to improved work-life balance, as individuals can better allocate time for work and personal activities.

2. Digital Meters Digital meters offer improved accuracy over analog counterparts and can provide instantaneous readings. They often have the capability to record and store data over time, which can be valuable for trend analysis.

In today’s industrial landscape, the management and filtration of gaseous emissions are critical for both environmental sustainability and the operational efficiency of manufacturing processes. Gas filters, specifically designed for the filtration of gaseous emissions, play a vital role in ensuring compliance with environmental regulations and promoting public health. This article delves into the significance of gas filters in various industrial applications and the technology behind them.

Considerations for Electric Water Heaters

Natural gas is a crucial energy source used in residential, commercial, and industrial applications around the world. However, its safe and efficient use relies heavily on maintaining appropriate pressure levels throughout the distribution system. This is where natural gas pressure regulators come into play. These devices ensure that gas is delivered at consistent and safe pressures, preventing potential hazards while optimizing energy delivery to end-users.

- Training Educate all personnel involved with gas systems on the importance of safety valves and the procedures for monitoring and maintaining them. Awareness can significantly reduce the risk of accidents.

Electric regulating valves are critical components in various industrial processes, allowing for precise control of flow rates, pressure, and temperature in fluid systems. These valves are actuated by electric signals, which enable them to adjust the flow of liquids and gases seamlessly. This article explores the functionality, benefits, and applications of electric regulating valves in various industries.

3. Easy Maintenance Most basket strainers feature a removable basket, allowing for straightforward cleaning and maintenance. This accessibility enables operators to perform regular checks and ensure the strainer's effectiveness without significant downtime.

The Role of Organizers The Architects of Success

The liquefaction process typically involves several stages, including pre-treatment to remove impurities like water, carbon dioxide, and sulfur compounds. Once purified, the gas is cooled in a series of heat exchangers. Finally, the LNG is stored in insulated tanks, maintaining its low temperature until it is ready for transport via specialized LNG carriers.

In industrial environments, where large volumes of gas are used, pressure regulators are critical for maintaining safety and operational efficiency. They are employed in processes such as welding, chemicals manufacturing, and food processing, where precise gas flow and pressure are vital for quality control and safety standards.

2. Equipment Protection Many devices, such as pumps, boilers, and pipelines, are designed to operate within specific pressure ranges. A pressure reducing valve safeguards these components from damage caused by pressure spikes or surges, thus extending their lifespan and reducing maintenance costs.

As the world continues to search for sustainable energy solutions, the role of natural gas in the energy mix remains significant. Pressure reducing stations are critical components in this equation, facilitating the safe and efficient distribution of natural gas from high-pressure transmission lines to end-users. By understanding their operation and importance, we can appreciate these unsung heroes of the energy infrastructure, ensuring that natural gas remains a reliable energy source for the future.

1. Tank Water Heaters These are the traditional water heaters that store a significant amount of hot water in a tank, usually ranging from 20 to 80 gallons. They heat the water continuously and keep it warm so that it is readily available whenever needed. While they are generally more affordable, they take up more space and can lead to higher energy bills due to heat loss.

Moreover, lifestyle modifications can also contribute significantly to pressure relief. Regular repositioning is a fundamental strategy; moving individuals every two hours can help mitigate the risk of pressure ulcers effectively. Educational programs aimed at caregivers and healthcare providers are likewise essential in promoting awareness about the importance of pressure relief techniques. Training individuals on proper techniques and the use of devices empowers them to take proactive measures in preventing pressure injuries.

Additionally, gas distribution stations often include odorization units that add a distinctive smell to natural gas, making it easier to detect leaks. This safety measure is crucial, as natural gas is colorless and odorless in its pure form. Regular maintenance and monitoring of gas distribution stations are vital to prevent leaks, which can lead to dangerous situations and significant economic losses.

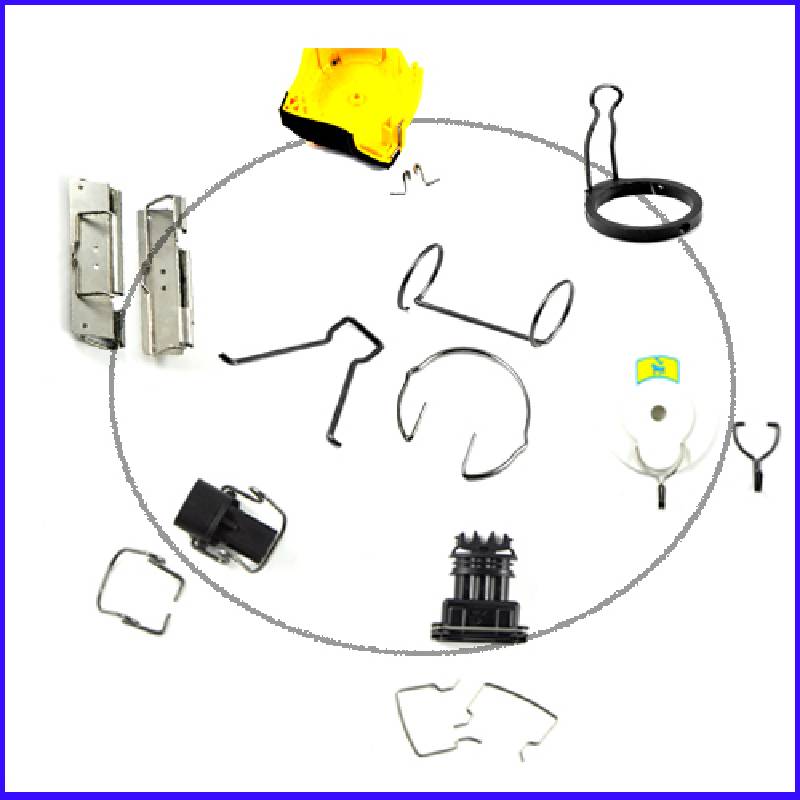

The curved lines introduce a softness and fluidity to the garden's geometry, breaking the rigid structure and adding a touch of whimsy The curved lines introduce a softness and fluidity to the garden's geometry, breaking the rigid structure and adding a touch of whimsy

The curved lines introduce a softness and fluidity to the garden's geometry, breaking the rigid structure and adding a touch of whimsy The curved lines introduce a softness and fluidity to the garden's geometry, breaking the rigid structure and adding a touch of whimsy curved plant supports.

curved plant supports. They can be used to mark the boundaries of a property or to outline flower beds and shrubs They can be used to mark the boundaries of a property or to outline flower beds and shrubs

They can be used to mark the boundaries of a property or to outline flower beds and shrubs They can be used to mark the boundaries of a property or to outline flower beds and shrubs 6 ft metal stakes. Metal stakes can also be used to support decorative lighting, banners, and other outdoor accessories, adding a touch of elegance to any outdoor space.

6 ft metal stakes. Metal stakes can also be used to support decorative lighting, banners, and other outdoor accessories, adding a touch of elegance to any outdoor space.Helical wall ties are unique in that they are designed to be twisted into the masonry during installation, providing a strong connection between the two layers of masonry

. These wall ties are often used in retrofit projects or in situations where traditional wall ties may not be suitable.

Dark annealed wire, also known as black annealed wire, is an annealed wire that is coated with a black oxide layer to provide corrosion resistance. This makes black annealed wire suitable for outdoor applications and ensures a longer service life, even in harsh environments.

Expansion springs, also known as long extension springs, are designed to expand or stretch when force is applied, making them suitable for applications requiring tension. Long Expansion springs are commonly used in applications such as trampolines, garage doors, and agricultural machinery.

Overall, adjustable compression springs are a versatile and practical solution for a wide range of applications where precise control over compression force is required. Their adjustability, durability, and ease of installation make them an ideal choice for engineers and designers looking for a reliable and flexible spring solution.

For larger applications, such as garage doors and trampolines, large extension springs are preferred. Large Extension Springs are capable of handling large loads while providing the necessary stretch to support heavy loads.