Maintenance and Troubleshooting

Maintenance and Troubleshooting

Benefits of Using Pressure Reducing Devices

In addition, the integration of gasification systems with other technologies, such as combined heat and power (CHP) systems, can enhance overall efficiency. For instance, the heat generated during the gasification process can be used for steam generation or to produce electricity through turbines. This combined approach maximizes the utilization of energy derived from waste materials, thus creating a more sustainable energy production cycle.

There are many different types of separators, each designed for specific applications. Some common types include gravity separators, cyclone separators, and magnetic separators. Each type of separator works in a unique way to separate components based on their properties, such as density, size, or magnetic susceptibility.

- Flush the Tank For tank water heaters, it is important to flush the tank annually to remove sediment buildup, which can affect performance and efficiency.

2. Pressure Regulators The heart of the PRS, these devices reduce the gas pressure to the desired level. They operate automatically and can adjust to varying flow demands.

Applications of Gas Pressure Vessels

They also work to ensure that companies provide accurate and transparent information to consumers, so they can make informed decisions about products and services They also work to ensure that companies provide accurate and transparent information to consumers, so they can make informed decisions about products and services

They also work to ensure that companies provide accurate and transparent information to consumers, so they can make informed decisions about products and services They also work to ensure that companies provide accurate and transparent information to consumers, so they can make informed decisions about products and services regulator.

regulator.

Safety Considerations

3. Automatic Shut-off Regulators These regulators are equipped with safety features that automatically shut off the gas flow in the event of a malfunction or leakage, ensuring safety in gas systems.

At its core, gas filtration involves the removal of particulates and gaseous pollutants from the air before they are released into the environment. This process is vital for industries such as power generation, pharmaceuticals, food processing, and chemical manufacturing, where numerous harmful byproducts can be emitted during production. By utilizing gas filtration systems, industries can comply with environmental regulations and reduce their ecological footprint.

In many countries, stringent regulations govern the installation and maintenance of gas safety valves. Compliance with these regulations is vital for ensuring public safety. Regulatory bodies require regular inspections and testing of safety devices to confirm their operational functionality. Failure to adhere to these standards can lead to legal consequences and, more importantly, pose serious safety risks to individuals and communities.

One of the most significant advantages of LNG is its lower environmental impact compared to traditional fossil fuels. When burned, LNG emits about 50% fewer carbon dioxide (CO2) emissions compared to coal and around 30% less than oil. Moreover, it produces virtually no sulfur dioxide (SO2) or particulate matter, which are significant contributors to air pollution and health problems. As countries grapple with climate change and strive for greener energy solutions, LNG presents itself as a cleaner bridge fuel that can support a transition towards more sustainable energy production.

4. Healthcare Sector Medical facilities use gas pressure vessels for storing gases such as oxygen and nitrous oxide, which are vital for patient care. Ensuring these vessels are maintained and inspected is essential to prevent any risk of failure in critical situations.

Additionally, in the field of manufacturing, sliders can transport machinery parts or tools required for assembly lines. Their versatility makes them an invaluable asset across sectors, promoting efficiency and innovation.

Definition and Importance

Safety Features

In summary, pressure relief valves are indispensable components in safeguarding industrial operations against the dangers of overpressure. Their simple yet effective design allows them to play a crucial role in protecting both equipment and personnel. By understanding their importance, working principles, and maintenance requirements, industries can ensure safer and more efficient operations. Investing in the right pressure relief valve and maintaining it properly is not just a matter of compliance—it is a fundamental aspect of operational excellence.

Operational safety should never be compromised; thus, regular training for personnel involved in the operation and maintenance of pressure vessels is essential. Understanding the principles of pressure vessel operation, potential hazards, and emergency procedures can significantly mitigate risks.

Natural gas is increasingly being recognized as a crucial element in the global energy landscape. As the world continues to grapple with the challenges posed by climate change and the urgent need for cleaner energy sources, natural gas emerges as a pragmatic solution that bridges the gap between traditional fossil fuels and renewable energy.

Another important filtration technology is the activated carbon filter. Activated carbon is highly effective in adsorbing impurities, particularly volatile organic compounds (VOCs) and sulfur compounds. By utilizing activated carbon filters, natural gas facilities can significantly reduce odor and harmful emissions, making the gas cleaner and more acceptable for consumer use.

Understanding Gas Pressure Regulator Valves Function and Importance

Finally, it’s important to think about the installation requirements and potential space constraints. Electric models are generally more compact than gas models, and installation can be more straightforward, especially in homes where gas lines are not available. However, it’s still crucial to have the right electrical supply and circuit to support the heater’s demand.

The Future of Gas Distribution Stations

The Organization of Natural Gas A Vital Energy Resource

Most PRVs are equipped with an adjustment screw that allows operators to set the desired output pressure according to the system's requirements. This adjustability makes PRVs versatile components suitable for various applications, from residential plumbing systems to large industrial plants.

Furthermore, engaging with stakeholders is a core principle of the smart regulator. Traditional regulatory practices often involved a top-down approach, where regulations were crafted without significant input from those they affected. However, the smart regulator seeks to incorporate feedback from industry experts, civil society, and the general public into the regulatory process. This approach not only leads to more effective regulations but also enhances compliance, as stakeholders are more likely to adhere to rules they helped shape.

1. Improved Performance By minimizing data volume, coalescing filters significantly enhance the performance of data processing systems. With less data to handle, databases can respond faster, and applications can operate more smoothly.

A natural gas filter separator is a piece of equipment designed to remove impurities, liquids, and particulates from natural gas. Typically, natural gas extracted from underground reservoirs often contains various contaminants, including water, hydrocarbons, and solid particles. These impurities can cause operational issues, reduce efficiency, and compromise the integrity of downstream equipment and processes. Therefore, a filter separator is employed to cleanse natural gas to meet specified quality standards.

When selecting a pressure regulator, various factors need to be considered, including the type of fluid (liquid or gas), the required flow rate, the inlet and outlet pressure ranges, and the material of construction. For example, corrosive fluids may necessitate regulators made from specialized materials to prevent degradation. Additionally, factors such as temperature, humidity, and the presence of particulates can affect regulator performance, so it's important to choose one that is designed to withstand the specific conditions of your application.

One of the key components of a pressure regulator is its internal mechanisms, which usually include a diaphragm, a spring, and a valve. The diaphragm responds to changes in pressure, while the spring exerts a force that helps maintain the desired set pressure. When the downstream pressure drops below the set point, the diaphragm moves to open the valve, allowing more fluid or gas to flow through and restore the pressure. Conversely, if the downstream pressure exceeds the set point, the diaphragm closes the valve to reduce the flow. This precise control mechanism ensures that pressures remain within the desired range, providing stability in the system.

Understanding Gas Regulators Importance and Functionality

4. Air Conditioning and Ventilation In HVAC systems, gas heat exchangers are instrumental in recovering energy from exhaust air, thus enhancing the efficiency of heating and cooling systems and promoting sustainability.

Aluminum window frames offer a sleek and modern aesthetic that complements various architectural styles. They can be extruded into almost any shape or size, allowing for a broad range of design options. Additionally, aluminum can be finished with powder coating or anodizing to provide a wide variety of colors and textures, enabling architects and designers to create unique and attractive appearances. This versatility has made aluminum a preferred choice for both residential and commercial buildings.

Aluminum is a highly recyclable and environmentally friendly material. The use of aluminum profiles for windows and doors contributes to sustainable development because this aluminum is a high quality material that can be recycled over and over again without losing its properties.

III. The choice of aluminum profile considerations

Reattach the roller assembly to the door using the removed screws. Tighten them securely, but avoid over-tightening, which could cause damage. If you removed a handle, reinstall it now, ensuring it lines up correctly.

All caps can be placed on metal and wooden railings and exterior fences

4. Budget

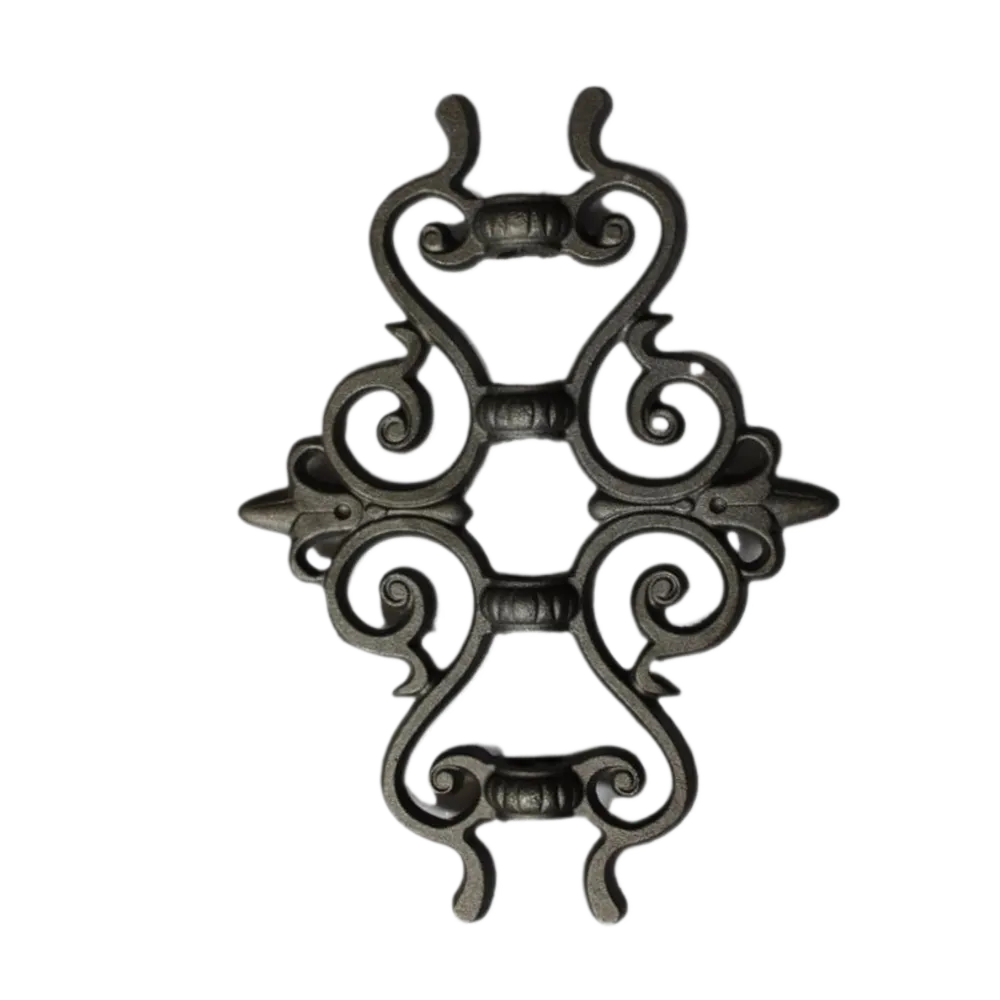

cast iron ornament. Unlike many other materials used in decorative arts, iron is resistant to corrosion and can withstand the elements, making it suitable for both indoor and outdoor use. This longevity ensures that these ornaments can be enjoyed for generations, often becoming cherished family heirlooms.

cast iron ornament. Unlike many other materials used in decorative arts, iron is resistant to corrosion and can withstand the elements, making it suitable for both indoor and outdoor use. This longevity ensures that these ornaments can be enjoyed for generations, often becoming cherished family heirlooms.The essence is to prevent nut or bolt head from spinning. You can use multiple fasteners in a single track and position freely.

Our Forged Steel products are expertly crafted to offer both durability and style, making them a timeless addition to any setting. The Cast Iron elements in our collection exude a classic, vintage charm, while our Aluminum pieces offer a lightweight and versatile option for a modern touch.

Mill-Finished, Anodizing, Powder Coating, PVDF, Electrophoresis, Wood Grain, Polishing, Brushing, etc

The essence is to prevent nut or bolt head from spinning. You can use multiple fasteners in a single track and position freely.

The low maintenance requirements of aluminium runners add to their appeal The low maintenance requirements of aluminium runners add to their appeal

The low maintenance requirements of aluminium runners add to their appeal The low maintenance requirements of aluminium runners add to their appeal aluminium door runners. They can be easily cleaned and require minimal upkeep, thus saving time and resources in the long run.

aluminium door runners. They can be easily cleaned and require minimal upkeep, thus saving time and resources in the long run.