Pressure reduction valves are an essential component in various systems, serving to enhance safety, efficiency, and process control. As industries continue to evolve, the importance of PRVs in maintaining stable and safe operational conditions cannot be overstated. Investing in quality PRVs not only ensures compliance and safety but also contributes to the overall effectiveness and reliability of systems across multiple applications. Understanding their function, types, and applications is crucial for engineers and operators working in pressure-sensitive environments.

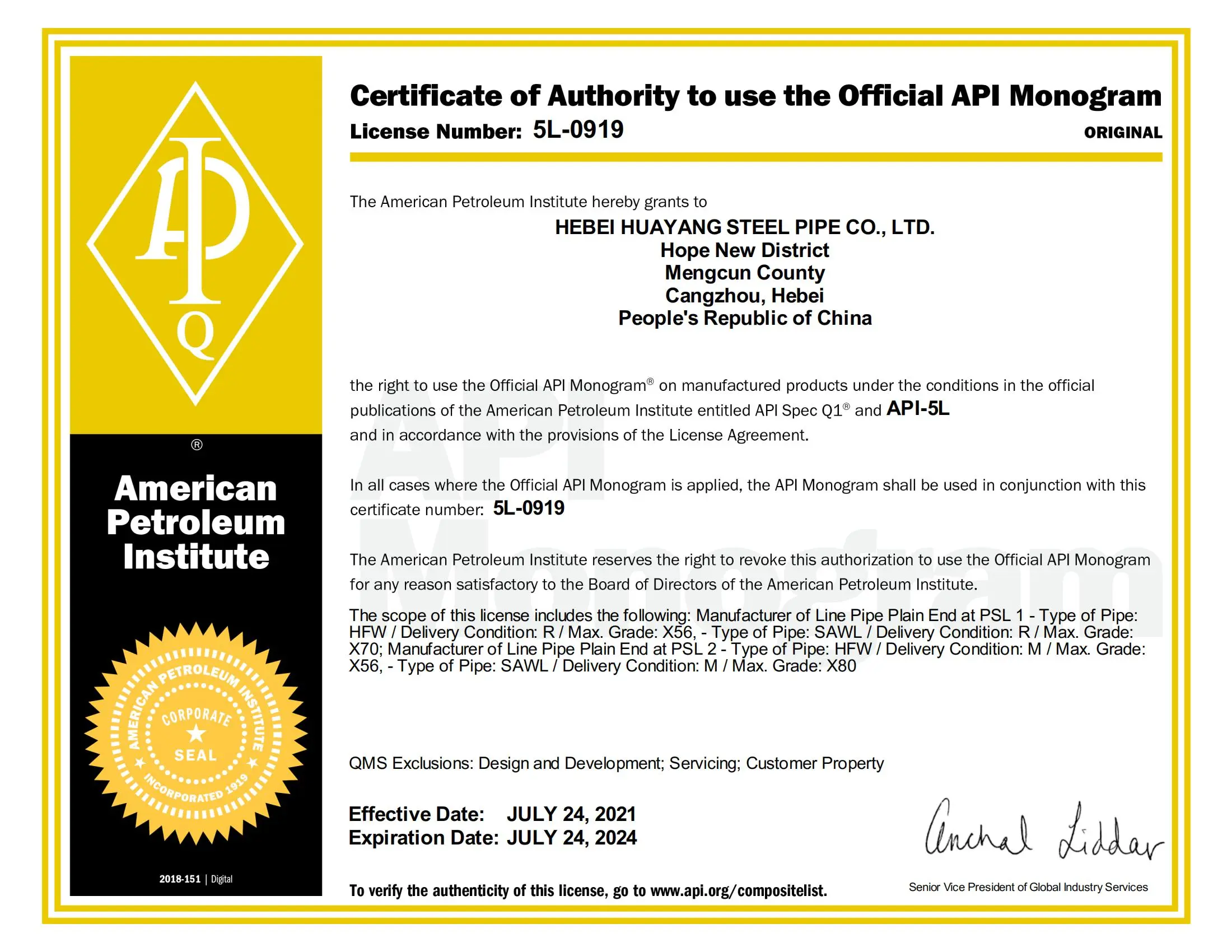

Responsible manufacturers adhere to strict environmental guidelines to minimize the ecological footprint of their operations Responsible manufacturers adhere to strict environmental guidelines to minimize the ecological footprint of their operations

Responsible manufacturers adhere to strict environmental guidelines to minimize the ecological footprint of their operations Responsible manufacturers adhere to strict environmental guidelines to minimize the ecological footprint of their operations

, Ltd, Ltd

, Ltd, Ltd