Pressure reduction valves are utilized across a wide range of sectors

Pressure reduction valves are utilized across a wide range of sectors

Natural gas valves are fundamental components of the energy infrastructure that support the safe and efficient delivery of natural gas. Their various types serve distinct functions, catering to the diverse needs of the industry. As the global emphasis on energy efficiency and safety increases, the development of advanced valve technologies will continue to play a critical role in meeting these demands. Understanding the importance of these valves not only highlights their functional significance but also underscores the commitment to maintaining a secure and sustainable energy future. The advancements in valve technology are a testament to the industry's dedication to innovation, enabling us to harness the benefits of natural gas while prioritizing safety and environmental responsibility.

The Importance of the Fasil Understanding Its Role in Culture and Society

In conclusion, heat exchangers are vital components in the natural gas industry, facilitating key processes such as liquefaction, regasification, and thermal management. Their efficient operation not only enhances the economic viability of natural gas systems but also supports the transition towards cleaner energy sources. As the industry evolves, the innovation surrounding heat exchanger technology will continue to play a crucial role in optimizing natural gas usage globally.

Pneumatic valves are essential to the efficiency and functionality of various automated systems. As industries continue to embrace automation, the importance of these components will only grow. Understanding the different types, functions, and advantages of pneumatic valves can help organizations leverage their potential, optimize their operations, and ensure safety in their processes. Whether for simple tasks or complex applications, pneumatic valves remain a cornerstone of modern pneumatic technology.

2. Ball Valves While typically used for on/off control, some ball valves are designed for throttling, thanks to their modification. They are favored for their quick operation and reliability.

Gas heat exchangers are crucial in modern industrial applications, promoting energy efficiency and sustainability. Their diverse designs cater to various needs, from power generation to environmental conservation. As industries continue to prioritize energy efficiency amid rising energy costs and environmental concerns, the importance of efficient heat exchangers for gases will only grow, paving the way for advancements in technology and engineering practices.

Pressure vessels find application in various industries, reflecting their versatility

In conclusion, City Gate Station stands as a beacon of modern urban transit, embodying the principles of connectivity, sustainability, and community engagement. It not only facilitates the movement of people but also enhances the quality of urban life through its multifaceted role as a transit hub, commercial center, and cultural venue. As cities continue to evolve, the significance of such well-designed, multifunctional stations will only increase, shaping the future of urban mobility and community interaction.

Types of Gas Valves

Conclusion

2. Activated Carbon Filters Used for the removal of volatile organic compounds (VOCs) and other odorous substances, activated carbon filters are vital in ensuring the purity of gas streams, especially in the food and beverage industries.

In conclusion, blood pressure regulator devices play a critical role in the management of hypertension, providing users with the ability to monitor their blood pressure accurately and efficiently. With advancements in technology, these devices continue to evolve, offering innovative features that enhance user experience and promote better health outcomes. As we move forward, fostering awareness and education about hypertension and its management will remain crucial in combating this prevalent health crisis.

- Safety By regulating the pressure of natural gas, these devices help prevent dangerous leaks and explosions that can occur if pressure is too high. Proper regulation ensures that appliances operate within their specified pressure limits.

The importance of these stations is further highlighted during peak demand seasons, such as winter, when households rely heavily on natural gas for heating. Efficient operation and management of gas distribution stations ensure that supply can meet demand, thus preventing shortages and ensuring safety.

Moreover, pressure regulators are designed to handle various conditions, including temperature fluctuations and changes in gas composition. They are built to withstand challenging environments, ensuring that the pressure management is reliable even under adverse conditions.

The Importance of Metering Systems in Modern Infrastructure

How Gas Pressure Reducers Work

One of the key advantages of smart regulators is their ability to improve energy efficiency. By constantly monitoring and adjusting the system parameters, smart regulators can optimize the energy usage to ensure that it is being used in the most efficient way possible. This not only reduces waste and lowers energy costs but also helps to reduce the overall carbon footprint of the system.

Functionality of Gas Pressure Regulators

In conclusion, natural gas regulators are vital components of the gas distribution network, ensuring the safe and efficient delivery of natural gas to users. Their ability to maintain appropriate pressure levels mitigates risks and supports the reliable operation of gas appliances. As technology advances, the future of natural gas regulation looks promising, with innovations that may enhance both safety and efficiency. Understanding the importance of these regulators helps consumers appreciate the complexities of natural gas delivery and the critical role that safety plays in energy consumption.

1. Coalescing Filters These filters effectively remove water and particulate contaminants from natural gas. By coalescing fine droplets of water into larger ones, coalescing filters facilitate the easy removal of liquid contaminants.

Understanding Shut-Off Valves A Key Component in Fluid Control Systems

At the heart of urban mobility, city gate stations are strategically located at the entry points of cities, making them the first point of contact for commuters arriving from surrounding regions. They often serve as intermodal terminals, where different forms of transportation converge, including buses, trains, subways, and even cycling and pedestrian pathways. The design and functionality of these stations are essential in facilitating seamless transfers between modes, thus reducing transit times and improving the overall travel experience for users.

Furthermore, the integration of gas boosters with renewable energy sources is becoming increasingly relevant. As the world moves towards a greener energy future, the combination of gas and renewables is often seen as a transitional strategy. Gas boosters can facilitate the smooth integration of intermittent renewable energy sources, such as wind and solar, into existing gas networks. By providing a reliable gas supply when renewable sources fall short, gas boosters help stabilize the grid and support the transition to a low-carbon economy.

A gas safety valve is a specialized device designed to prevent excessive pressure buildup within gas systems. It operates by releasing gas when the pressure exceeds a predetermined level, effectively safeguarding pipelines, equipment, and personnel from the dangers associated with over-pressurization. These valves are typically used in gas storage facilities, processing plants, and other operational environments that involve gas transportation.

The working principle of a pressure reducing device can be understood through its main components the inlet pressure port, the outlet pressure port, and the regulating mechanism

. When a high-pressure fluid enters the device, a sensing element within the regulator detects the pressure and adjusts the mechanism to maintain the desired output pressure. This is typically achieved through a spring-loaded diaphragm or piston that responds to changes in pressure.Conclusion

In conclusion, gasification equipment represents a critical component in the pursuit of sustainable energy solutions. Its versatility, efficiency, and environmental benefits position gasification as a key technology in transforming waste into valuable energy resources. With ongoing advancements and increasing global emphasis on sustainability, the role of gasification will undoubtedly continue to expand in the coming years, contributing to a cleaner and more sustainable energy future.

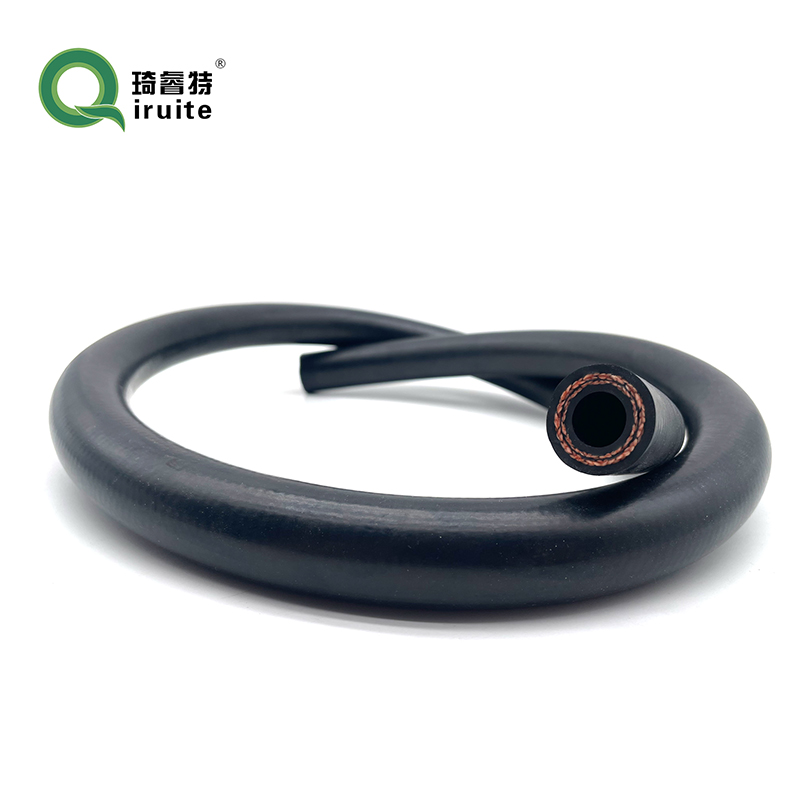

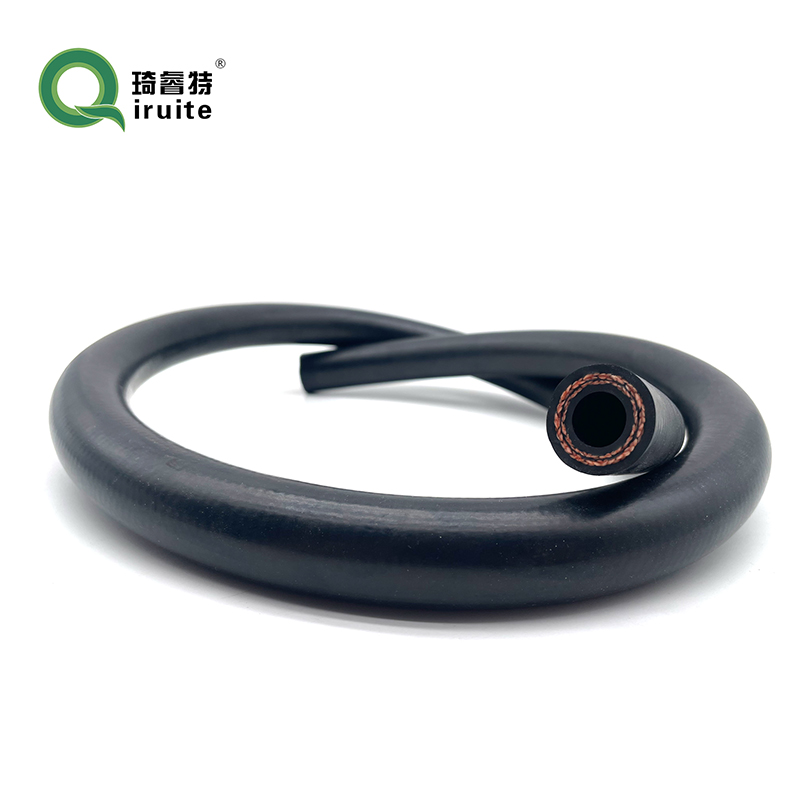

Furthermore, the stainless steel braiding acts as a shield against external impacts, reducing the risk of damage that could lead to leaks or failure Furthermore, the stainless steel braiding acts as a shield against external impacts, reducing the risk of damage that could lead to leaks or failure

Furthermore, the stainless steel braiding acts as a shield against external impacts, reducing the risk of damage that could lead to leaks or failure Furthermore, the stainless steel braiding acts as a shield against external impacts, reducing the risk of damage that could lead to leaks or failure stainless steel braided power steering hose kits.

stainless steel braided power steering hose kits. Once the issue has been identified, the damaged section of the hose will need to be replaced Once the issue has been identified, the damaged section of the hose will need to be replaced

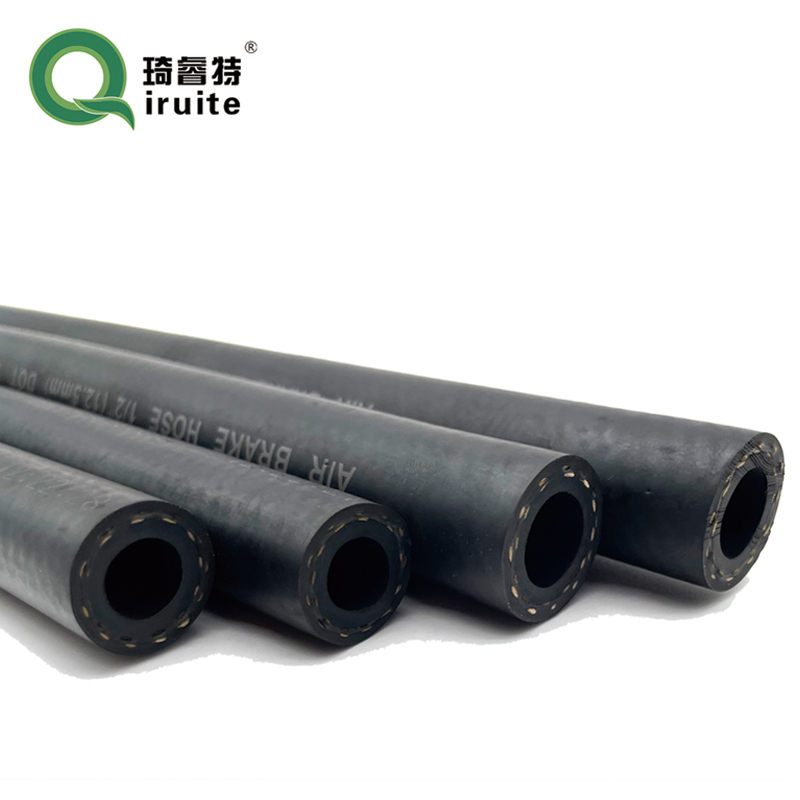

Once the issue has been identified, the damaged section of the hose will need to be replaced Once the issue has been identified, the damaged section of the hose will need to be replaced car ac rubber hose repair.

car ac rubber hose repair.

Labor costs can vary depending on the location and experience of the mechanic performing the work Labor costs can vary depending on the location and experience of the mechanic performing the work

Labor costs can vary depending on the location and experience of the mechanic performing the work Labor costs can vary depending on the location and experience of the mechanic performing the work how much does a power steering hose cost to replace. In some cases, you may be able to perform the replacement yourself, which can save you money on labor costs. However, if you are not comfortable performing the work yourself, it's best to leave it to a professional mechanic.

how much does a power steering hose cost to replace. In some cases, you may be able to perform the replacement yourself, which can save you money on labor costs. However, if you are not comfortable performing the work yourself, it's best to leave it to a professional mechanic. 4 inch waste coupling. It can be used in a wide range of applications, including industrial processes, construction sites, and even household plumbing. Its compact size and ease of use make it a popular choice among professionals and do-it-yourselfers alike.

4 inch waste coupling. It can be used in a wide range of applications, including industrial processes, construction sites, and even household plumbing. Its compact size and ease of use make it a popular choice among professionals and do-it-yourselfers alike.