Importance of Pressure Reduction Stations

Importance of Pressure Reduction Stations

Pressure regulators come in a variety of forms, tailored to different applications. The two primary types are

Understanding Pressure Reducing Regulators A Comprehensive Overview

In Writing and Communication

Moreover, the gasification process provides a pathway for waste management

. As societies grapple with mounting waste challenges, gasifiers can convert municipal solid waste, agricultural residues, and other organic matter into valuable energy resources. This not only diverts waste from landfills but also mitigates the environmental impact associated with waste disposal, contributing to a circular economy.

In addition to liquefaction and regasification, heat exchangers are extensively used in natural gas processing plants, where they are involved in drying, purification, and heating of the gas. For instance, before natural gas is transported in pipelines, it often requires dehydration to remove water vapor, which can cause problems such as hydrate formation during transportation. Heat exchangers can assist in this process, leading to purer and more efficient gas delivery.

3. Safety Shut-off Valves These valves are designed to cut off the gas supply in case of a malfunction or emergency. For example, if a gas leak is detected, the safety shut-off valve will close to prevent hazardous situations.

Furthermore, the growing emphasis on safety regulations and standards across various sectors has escalated the importance of reliable gas pressure regulators. They contribute significantly to risk management and compliance with industry standards, thereby enhancing overall safety in gas handling and usage.

In conclusion, coalescing filters are a vital component in various industrial applications due to their efficiency in removing liquid contaminants from gases. Their ability to enhance equipment performance, lower operational costs, and promote environmental sustainability makes them indispensable in modern engineering practices. As industries continue to evolve and place more emphasis on efficiency and environmental responsibility, the demand for effective filtration solutions like coalescing filters is expected to grow. Understanding their functionality and applications is essential for engineers and professionals striving to improve processes while safeguarding the environment.

In the energy sector, heat exchangers are crucial in geothermal plants, nuclear power plants, and during the cooling of steam in conventional power stations. This versatility underscores their importance in developing sustainable and energy-efficient systems to combat global warming and reduce carbon footprints.

By prioritizing the installation and regular servicing of gas safety valves, companies can significantly enhance operational safety, protect their workforce, and maintain compliance with regulatory standards. Ultimately, these measures contribute to fostering a safer industrial environment where the risks associated with gas handling are effectively managed.

Natural gas is primarily composed of methane and is abundant in various regions worldwide. Its ease of extraction and transportation has made it a favored choice for energy generation, heating, and as a chemical feedstock. One of the most significant advantages of natural gas is its efficiency; modern gas-fired power plants can achieve high levels of efficiency, converting a larger percentage of fuel into electrical energy compared to other fossil fuels.

In recent years, the global energy landscape has shifted dramatically, with natural gas taking center stage as a cleaner alternative to coal and oil. Among its various forms, Liquefied Natural Gas (LNG) has emerged as a crucial player, offering both environmental benefits and increased energy security to nations around the world.

2. Efficiency Gas regulators contribute to the efficiency of gas appliances. When the gas is supplied at the correct pressure, appliances can operate more effectively, leading to reduced fuel consumption and lower operational costs. This is particularly significant in industrial settings, where even minor inefficiencies can result in substantial financial losses.

Most gas pressure reducers also feature safety mechanisms, such as relief valves, which relieve excess pressure to prevent potential backflow or over-pressurization

. This ensures not only efficiency but also safety, as it helps in preventing equipment damage and ensuring compliance with safety regulations.

In conclusion, natural gas filters play a crucial role in ensuring the quality, safety, and efficiency of natural gas as an energy source. As the world increasingly moves toward cleaner energy solutions, the importance of effective filtration technologies will only grow. By investing in and implementing advanced filtration systems, the natural gas industry can not only meet regulatory requirements but also contribute significantly to the sustainable energy goals of the future.

The primary components of a gas pressure reducer include an inlet port, an outlet port, a diaphragm housing, and typically, an adjustment mechanism

. By turning the adjustment screw, users can modify the spring tension, thereby changing the outlet pressure to suit specific requirements.What is a Relief Valve?

The working principle of a gas pressure regulating valve involves a mechanical mechanism that senses the outlet pressure and adjusts the flow of gas accordingly. Typically, these valves consist of a diaphragm, spring, and an adjustable set-point. When gas enters the valve at a higher pressure, the diaphragm moves in response to the pressure differential. If the outlet pressure exceeds the preset level, the diaphragm closes, restricting gas flow. Conversely, if the outlet pressure drops below the desired level, the diaphragm opens, allowing more gas to flow through.

4. Combination Valves These valves combine the functions of both relief and safety valves in one unit, providing versatility for different pressure management needs.

Conclusion

Applications in Daily Life and Industry

Understanding Gas Regulators A Vital Component of Gas Systems

Technological Advancements

Gas pressure reducing valves are utilized in a wide range of applications across different sectors

The operation of a pressure regulator is largely based on the principle of balance between the inlet pressure, outlet pressure, and the spring tension within the device. As the high-pressure fluid enters the regulator, it acts against a diaphragm, which moves in response to changes in pressure. When the output pressure rises above the predetermined level, this movement causes a valve to close, restricting the flow. Conversely, if the output pressure drops, the valve opens, allowing more fluid to flow through. This feedback mechanism ensures that the output pressure remains steady, regardless of fluctuations in the input.

Pressure regulators work by automatically adjusting the flow of gas based on the demand from users. They can sense changes in both inlet pressure (the pressure coming into the regulator) and outlet pressure (the pressure going out to the consumers). When the outlet pressure exceeds a preset level, the regulator responds by restricting gas flow, thereby maintaining consistent delivery pressure. Conversely, if the outlet pressure drops, the regulator allows more gas to flow, ensuring that consumers receive the necessary amount of gas for their needs.

Regular maintenance and testing of gas pressure regulators are also essential to ensure their reliability. This includes checking for leaks, ensuring the mechanism is functioning correctly, and replacing any worn or damaged parts. By prioritizing maintenance, industries can significantly reduce the risk of accidents and improve the overall safety of their operations.

- Oil and Gas In upstream and downstream operations, maintaining optimal pressure levels is crucial for extraction and processing efficiency. Skids are used in wellhead control, pipeline pressure management, and during the fueling process.

Gas pressure vessels are a cornerstone of modern industrial processes, providing safe and efficient means to store and transport gases. Their design and construction require meticulous engineering and adherence to strict safety standards to mitigate potential hazards. As industries continue to evolve and expand, the demand for advanced gas pressure vessels will only increase, necessitating ongoing innovation and commitment to safety and efficiency. Understanding these vessels and their applications is essential for anyone involved in fields reliant on gas storage and handling.

3. Regulatory Compliance Many industries are subject to stringent regulations regarding pressure control. Implementing PRVs helps companies comply with these standards, avoiding potential fines and ensuring the safety of working environments.

How Gas Pressure Reducing Valves Work

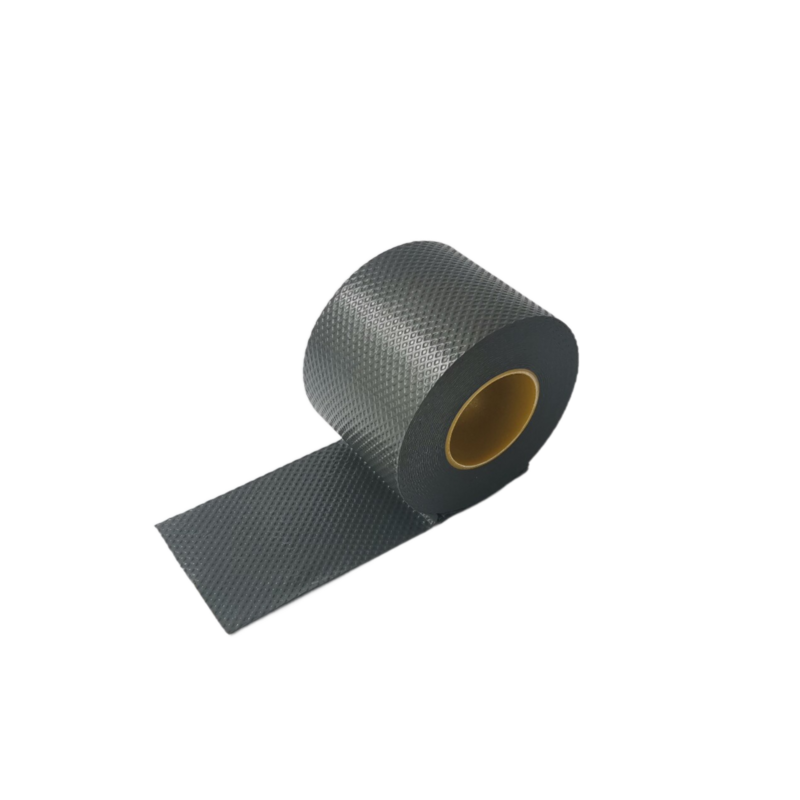

Moreover, its flexibility allows it to conform to the contours of the vehicle, providing a snug and secure fit around the wires Moreover, its flexibility allows it to conform to the contours of the vehicle, providing a snug and secure fit around the wires

Moreover, its flexibility allows it to conform to the contours of the vehicle, providing a snug and secure fit around the wires Moreover, its flexibility allows it to conform to the contours of the vehicle, providing a snug and secure fit around the wires adhesive cloth automotive wiring harness tape.

adhesive cloth automotive wiring harness tape.

As with any adhesive, there are actions to ensure your project is adequately covered and protected. To properly install butyl tape, follow these simple steps.

3M also makes an electrical tape made of silicone rubber for applications where Class “H” (180°C/356°F) temperatures are encountered i.e., silicone rubber cables.

In summary, 50mm black insulation tape is a multifaceted tool that proves invaluable in various fields. Whether used for electrical insulation, repairs, construction, or creative projects, its reliability and ease of use make it a staple in any toolbox. The combination of its durability, versatility, and effectiveness ensures that it will continue to play a crucial role in both professional and personal applications. As industries evolve and innovation continues, the essential nature of products like black insulation tape will inevitably remain steadfast, adapting to meet the ever-changing needs of users.

As industries move towards more sustainable practices, it's worth considering suppliers who prioritize eco-friendly materials and production methods. Suppliers that utilize sustainable manufacturing processes or offer recyclable products may align better with your company’s environmental goals.

Width: Available in 19mm and 25mm

We are pleased to stock a number of different self-fusing tapes. All are electrically insulating though some are often used for sealing work (e.g. fixing a leaking hose) in addition to electrical applications.

In conclusion, car harness tape may seem like a minor component in your vehicle, but it plays a crucial role in maintaining the integrity of your car's electrical system. By investing in high-quality tape and taking the time to properly secure and protect your wiring harnesses, you can avoid potential electrical issues and ensure the longevity of your vehicle. Remember, when it comes to car maintenance, every detail matters – including the humble car harness tape.

2. Cut to length.It is important to have the tape at the correct length before applying it. Once it adheres. it will be difficult to remove.