Design Considerations

Design Considerations

Understanding Gas Separator Filters Importance and Functionality

From a technological perspective, advancements in charging technology are continually developing. The emergence of ultra-fast charging systems capable of delivering even higher power levels—which could reduce charging times to mere minutes—holds promise for the future of electric mobility. Coupled with increasing battery capacity and efficiency, the vehicle range will likely extend even further, thereby making electric vehicles even more appealing to the average consumer.

2. Efficiency Maintaining a constant pressure can lead to more efficient fluid flow and energy use, contributing to lower operational costs.

1. Pressure Ratings Pipes must be rated for the maximum pressure they will encounter, often expressed in pounds per square inch (psi). This rating informs engineers of the suitable material and thickness required.

Understanding Gas Pressure Reducing Valves

Design and Construction

Moreover, PRVs play a crucial role in renewable energy applications, such as hydroelectric power generation, where they regulate water pressure to maintain consistent turbine operation. They are also essential in HVAC systems, where maintaining balanced pressure is key to ensuring comfortable and efficient climate control.

Types of Relief Valves

In today's fast-paced industrial environment, the need for efficient and reliable solutions for managing pressure has become increasingly critical. One such solution that has gained prominence is the decompression skid. A decompression skid is a specialized piece of equipment designed to safely and efficiently reduce high-pressure gas or liquid to a lower pressure. This vital apparatus plays a crucial role across various sectors, including oil and gas, chemical processing, and even in renewable energy applications.

Understanding Coalescing Filters Enhancing Data Processing Efficiency

When a system’s pressure exceeds a predetermined limit, the PRV activates, allowing the excess pressure to escape. This release of pressure can prevent catastrophic failures such as explosions, equipment damage, or even loss of life. Thus, the reliability of pressure relief valves is paramount for ensuring safe operations in industries such as oil and gas, chemical processing, and power generation.

- Efficiency Properly functioning gas valves contribute to the overall efficiency of the gas system. They ensure that the right amount of gas is delivered to appliances, minimizing waste and optimizing energy consumption. This efficiency not only saves money but also reduces environmental impact.

Overall, natural gas regulators are essential components of the natural gas industry, ensuring the safe and efficient delivery of this valuable energy source to consumers around the world. By carefully controlling the pressure of the gas, regulators help maintain the reliability and performance of the distribution system while also minimizing the risk of accidents and environmental damage. As the demand for natural gas continues to grow, the role of natural gas regulators will only become more important in ensuring the continued supply and use of this clean and versatile energy source.

Importance of Pressure Reducing Valves

2. Ball Valves Recognizable by their spherical disc (the ball), these valves are known for their quick operation; just a quarter turn is necessary to open or close them. They are widely used for their durability and ability to maintain a tight seal with low leakage rates.

In manufacturing processes, pressure reducers play a significant role in managing hydraulic and pneumatic systems. By maintaining stable pressure levels, they help enhance the efficiency of machinery, reduce wear and tear, and prevent catastrophic failures caused by over-pressure conditions.

A gas pressure reducing station typically consists of several components including pressure regulators, valves, measurement devices, and sometimes, heating elements. The primary function is to reduce the high pressure of gas received from the transmission pipelines to the lower pressures required for distribution systems. This process is essential to prevent damage to downstream equipment and to ensure the safety of both the users and the infrastructure.

Importance of Valves in Safety

Next, the gas reaches the pressure control valves. These valves are the heart of the pressure reduction process. They automatically adjust to control the pressure level, ensuring that the gas is delivered at the correct pressure for safe usage. Depending on the demand and the required pressure, these valves can open or close to maintain the desired flow rate.

One of the primary advantages of cyclone separators is their efficiency. They provide a cost-effective solution for dust control with minimal maintenance requirements. Cyclones can handle large volumes of air or liquid and operate effectively across a wide range of flow rates and particle sizes. Additionally, they do not require complex moving parts, which reduces the likelihood of mechanical failure.

They help to track the flow of products in and out of the facility, as well as monitor stock levels to ensure that there are enough products on hand to fulfill customer orders They help to track the flow of products in and out of the facility, as well as monitor stock levels to ensure that there are enough products on hand to fulfill customer orders

They help to track the flow of products in and out of the facility, as well as monitor stock levels to ensure that there are enough products on hand to fulfill customer orders They help to track the flow of products in and out of the facility, as well as monitor stock levels to ensure that there are enough products on hand to fulfill customer orders distribution station.

distribution station.The operation of a filter separator is usually broken down into several key stages. Initially, the mixture enters the separator's chamber, where it encounters a perforated or filter media that captures solid particulates. This media is crucial as it determines the effectiveness and efficiency of the filtration process.

Moreover, automation and remote monitoring capabilities have transformed the gas industry. Operators can now control and monitor safety valves from a distance, enabling quicker responses to alarms or irregular readings. This is particularly beneficial for industrial facilities that manage large volumes of natural gas and require stringent safety measures.

- Water Supply Systems Ensuring potable water reaches households and businesses efficiently.

Applications of Pressure Reducing Valves

One of the most critical aspects of natural gas valves is their role in safety. Natural gas is flammable and can pose significant hazards if not managed properly. Valves are equipped with various safety features to mitigate risks. For example, pressure relief valves are used to relieve excess pressure, preventing potential explosions. Additionally, automated shut-off valves can quickly halt the flow of gas in the event of a leak or other emergency, protecting both people and infrastructure.

Heat exchangers play a critical role in various industrial applications, particularly in the natural gas sector. Their primary function is to efficiently transfer heat between two or more fluids without mixing them, which is essential for optimizing energy consumption and enhancing system efficiency. In the context of natural gas, heat exchangers contribute to several processes, including liquefaction, regasification, and the general heating and cooling of gas streams.

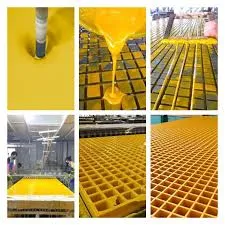

Vinyl ester: A chemically resistant system that provides the highest level of corrosion protection. Standard colors: Yellow, Dark Gray, and Orange. Equivalent to Fiberglass Grating Vinyl Ester and Strongwell Duragrate VE.

tunnel bench drilling bit. These bits are designed to create straight and uniform boreholes, which are necessary for the alignment of the tunnel. By maintaining precision in the drilling process, tunnel bench drilling bits help to ensure that the tunnel is built according to specifications and meets safety standards.

tunnel bench drilling bit. These bits are designed to create straight and uniform boreholes, which are necessary for the alignment of the tunnel. By maintaining precision in the drilling process, tunnel bench drilling bits help to ensure that the tunnel is built according to specifications and meets safety standards.

It also reduces thermal conductivity, making it suitable for use around high-heat equipment without risking warping or deformation It also reduces thermal conductivity, making it suitable for use around high-heat equipment without risking warping or deformation

It also reduces thermal conductivity, making it suitable for use around high-heat equipment without risking warping or deformation It also reduces thermal conductivity, making it suitable for use around high-heat equipment without risking warping or deformation pultruded fiberglass grating.

pultruded fiberglass grating.

The design also incorporates noise reduction measures, contributing to a safer and more comfortable working environment for operators The design also incorporates noise reduction measures, contributing to a safer and more comfortable working environment for operators

The design also incorporates noise reduction measures, contributing to a safer and more comfortable working environment for operators The design also incorporates noise reduction measures, contributing to a safer and more comfortable working environment for operators pusher leg rock drill.

pusher leg rock drill. For instance, wet FGD systems are highly efficient, capable of removing over 95% of sulfur dioxide from flue gas, making them ideal for large-scale power plants For instance, wet FGD systems are highly efficient, capable of removing over 95% of sulfur dioxide from flue gas, making them ideal for large-scale power plants

For instance, wet FGD systems are highly efficient, capable of removing over 95% of sulfur dioxide from flue gas, making them ideal for large-scale power plants For instance, wet FGD systems are highly efficient, capable of removing over 95% of sulfur dioxide from flue gas, making them ideal for large-scale power plants fgd scrubber.

fgd scrubber.