.

Conclusion

The Impact of Vehicle-Mounted Equipment on Modern Transportation

- Chemical Manufacturing In the chemical industry, gas pressure vessels are used for storing reaction gases, as well as for transporting chemicals in gaseous form. Due to the volatile nature of many chemicals, employing robust pressure vessels is essential for safety.

Basket strainers are critical components in various industrial applications, particularly in the field of fluid management. They serve a primary function—protecting pumps, valves, and other equipment from contaminants that can cause damage or reduce efficiency. This article delves into the importance, types, and benefits of basket strainers, highlighting their role in maintaining system integrity.

1. Directional Control Valves These valves manage the path that air takes within a system. They can control the switching between different actuators and are commonly used in applications requiring precise movement, such as robotics and automation.

Blood pressure, a vital sign that reflects the force of blood against the walls of our arteries, plays a crucial role in our overall health. Maintaining optimal blood pressure levels is essential for preventing various health issues such as heart disease, stroke, and kidney problems. As medical technology continues to advance, blood pressure control devices have emerged as valuable tools in the management and monitoring of hypertension.

Moreover, by improving the quality of natural gas, these devices enhance the overall efficiency of gas processing plants. Cleaner gas translates into better combustion properties, leading to more efficient energy production, lower emissions, and reduced operational costs.

In today’s complex and rapidly evolving world, regulators play a critical role in maintaining order, safety, and fairness across various sectors of society. From finance and healthcare to technology and environmental protection, regulatory bodies are essential in shaping the framework within which businesses and individuals operate. This article explores the significance, challenges, and future of regulatory agencies.

3. Energy Sector In the energy sector, gas pressure regulators are used in the transportation and distribution of natural gas. They help maintain the pressure required for safe delivery to homes and businesses, playing a vital role in energy supply systems.

Conclusion

A gas regulator consists of several key components, including the body, inlet and outlet connections, an internal spring, and a diaphragm. The diaphragm is a flexible membrane that moves in response to pressure changes. When high-pressure gas enters the regulator, it acts on the diaphragm, which in turn compresses a spring. This movement adjusts the size of an internal valve that controls the flow of gas to the outlet.

Gas pressure reducing valves (PRVs) are critical components in various applications that utilize gas as a primary energy source. These valves are designed to ensure that gas is delivered at a constant pressure, regardless of fluctuations in the source pressure, making them essential in both residential and industrial contexts. By effectively controlling gas pressure, PRVs play a significant role in enhancing safety, efficiency, and functionality of gas-powered systems.

1. Feedstock Preparation Unit The first stage in the gasification process involves the preparation of the feedstock. This unit is responsible for size reduction, drying, and sometimes, the pretreatment of the feed materials. Effective feedstock preparation enhances the overall efficiency of the gasification process.

- Inspection Regularly inspect the device for leaks, corrosion, and mechanical wear.

2. Industrial Processes In manufacturing, pressure regulators control the pressure of air and gases used in pneumatic systems, ensuring tools and machinery function correctly. This regulation supports consistent production quality and reduces the likelihood of equipment malfunction.

Gas pressure regulators can be categorized into different types based on their design and application. One common type is the first-stage regulator, typically used in high-pressure applications. It reduces the pressure from the gas supply source to a lower level suitable for further regulation. The second-stage regulator further decreases the pressure to the desired level for end-use applications. Another type is the adjustable regulator, which allows users to set the output pressure according to their specific needs, making it versatile for various applications.

2. Quick Installation Skid mounted equipment is designed for rapid deployment. The pre-assembled units can be quickly connected to existing infrastructure, significantly reducing the time from setup to operation. This is crucial for industries where downtime translates to significant financial losses.

How Does a Gas Regulator Work?

- Environmental Impact Natural gas is a cleaner-burning fossil fuel compared to coal and oil. Efficient distribution stations help maximize the use of natural gas in energy production, thus reducing greenhouse gas emissions.

Despite their advantages, implementing coalescing filters does come with challenges. For instance, the design of an effective coalescing algorithm requires a deep understanding of the data characteristics and patterns, as poorly designed filters may either discard critical information or fail to optimize data effectively. Moreover, there is a need for real-time processing capabilities to ensure that the filtering occurs without introducing significant delays.

Principles of Gas Heat Exchangers

In industrial applications, the need for stringent pressure regulation is even more paramount. Industries that rely on gas for manufacturing processes, chemical reactions, or power generation depend on these valves to maintain precise control over gas pressures. Any inconsistency can lead to production downtime, equipment damage, or even safety hazards.

At its core, a gas heat exchanger facilitates the transfer of heat from a hot gas to a cooler fluid, which can be either a gas or a liquid. This process is central to many applications, including power generation, HVAC systems, chemical processing, and even automotive engineering. The design and operational principles of gas heat exchangers are influenced by the specific requirements of these applications.

4. Process Control Regulators allow for greater control over processes, resulting in improved product quality and consistency.

Natural gas is ultimately used in various applications, from heating homes to fueling vehicles. Several pieces of equipment facilitate its usage

Conclusion

Gas pressure reducing valves are utilized in a wide range of applications across different sectors

As the energy landscape continues to evolve, the importance of natural gas filters cannot be overstated. They serve as a vital line of defense against contamination, ensuring that the natural gas delivered to consumers is safe and efficient. In a world increasingly conscious of energy sustainability and environmental impact, investing in high-quality filtration technology is imperative for natural gas operators. It not only safeguards their equipment and enhances operational performance but also contributes positively to the broader goal of cleaner energy production.

1. Energy Efficiency Electric water heaters, especially tankless models, can be highly energy-efficient. They eliminate standby heat loss, which occurs in traditional tank heaters, where heat escapes from the stored water.

The operation of a shut-off valve primarily depends on its design

The use of Low-E safety glass is also an effective strategy for noise reduction. The laminated layer in safety glass can significantly dampen sound transmission, making it ideal for buildings located in noisy urban environments or near highways. Consequently, occupants can enjoy a quieter and more comfortable living or working space, enhancing overall well-being.

They offer a glimpse into one's own reflection, yet present it through a lens tinted by the rich history and cultural significance of silver They offer a glimpse into one's own reflection, yet present it through a lens tinted by the rich history and cultural significance of silver

They offer a glimpse into one's own reflection, yet present it through a lens tinted by the rich history and cultural significance of silver They offer a glimpse into one's own reflection, yet present it through a lens tinted by the rich history and cultural significance of silver sterling silver mirrors. One cannot help but contemplate the depth of character captured in the reflection of a sterling silver mirror—an intersection of personal identity and timeless luxury.

sterling silver mirrors. One cannot help but contemplate the depth of character captured in the reflection of a sterling silver mirror—an intersection of personal identity and timeless luxury.1. Safety and Durability One of the most significant advantages of tempered glass is that it is much tougher than regular glass. When shattered, tempered glass breaks into small, blunt pieces, reducing the risk of injury. This safety feature makes it an ideal choice for various applications, including windows, doors, and shower enclosures.

This is particularly beneficial in commercial spaces such as offices and retail stores, where natural light can boost productivity and customer satisfaction This is particularly beneficial in commercial spaces such as offices and retail stores, where natural light can boost productivity and customer satisfaction

This is particularly beneficial in commercial spaces such as offices and retail stores, where natural light can boost productivity and customer satisfaction This is particularly beneficial in commercial spaces such as offices and retail stores, where natural light can boost productivity and customer satisfaction low iron ultra clear glass. Additionally, low iron ultra clear glass is highly resistant to UV radiation, which can help protect furniture, flooring, and artwork from harmful sun damage.

low iron ultra clear glass. Additionally, low iron ultra clear glass is highly resistant to UV radiation, which can help protect furniture, flooring, and artwork from harmful sun damage.Historically, mirrors have been symbols of vanity and self-reflection. The earliest mirrors were made from polished stone and metal, but the invention of glass in the 13th century marked a turning point in the production of mirrors. By the time the Victorian era emerged, mirrors became integral to home decor, and the antique silver oval mirror became a favored style. Often adorned with intricate designs, these mirrors were not merely tools for reflection; they were a statement of luxury and refinement.

In the ever-evolving world of interior design, the incorporation of unique materials can transform traditional spaces into stunning sanctuaries that reflect personal style and taste. One such captivating material that has captured the hearts of many designers and homeowners alike is acid etched frosted glass. This innovative material not only serves functional purposes but also enhances the aesthetic appeal of various environments.

.

.When considering the price of 6mm frosted glass, it is crucial to weigh the costs against the many benefits it provides. Its combination of aesthetic appeal, privacy, durability, and ease of maintenance makes it a worthy investment for a wide range of applications. While the initial price may be higher than other glass options, the long-term benefits often justify the expense. Ultimately, choosing 6mm frosted glass not only enhances the look and functionality of a space but also adds value to your property. Whether you're building a new home, renovating an office, or designing a commercial space, 6mm frosted glass could be the ideal choice for your needs.

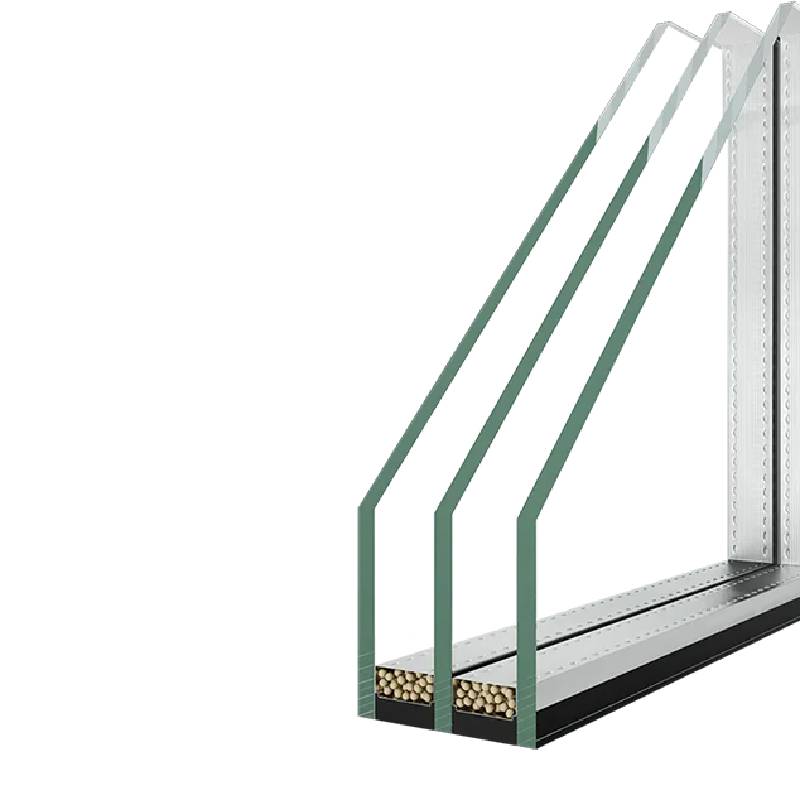

Many varieties are thermally insulated, helping to regulate indoor temperatures and potentially reducing energy bills Many varieties are thermally insulated, helping to regulate indoor temperatures and potentially reducing energy bills

Many varieties are thermally insulated, helping to regulate indoor temperatures and potentially reducing energy bills Many varieties are thermally insulated, helping to regulate indoor temperatures and potentially reducing energy bills igu glass for sale. By letting in natural light while keeping heat loss to a minimum, these glasses contribute to a more sustainable living environment.

igu glass for sale. By letting in natural light while keeping heat loss to a minimum, these glasses contribute to a more sustainable living environment.In conclusion, mirror railings for stairs represent a bold design choice that does not compromise safety for style. As more homeowners seek innovative ways to infuse elegance into their spaces, these railings stand out as a fantastic option, merging functionality with a striking visual presence.

As light passes through the intricate patterns, it is scattered in all directions, creating a warm and inviting atmosphere As light passes through the intricate patterns, it is scattered in all directions, creating a warm and inviting atmosphere

As light passes through the intricate patterns, it is scattered in all directions, creating a warm and inviting atmosphere As light passes through the intricate patterns, it is scattered in all directions, creating a warm and inviting atmosphere wave pattern glass. This makes the wave pattern glass an ideal choice for lighting fixtures, such as table lamps or pendant lights. The soft glow emitted by these fixtures will create a cozy and relaxing ambiance in any room.

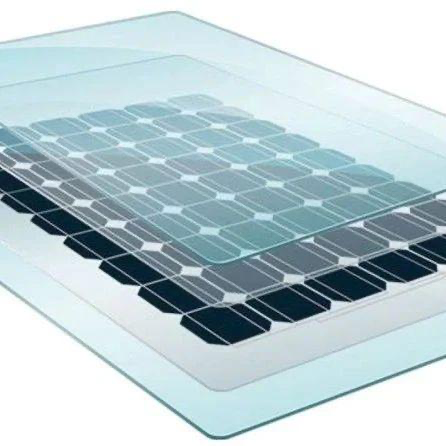

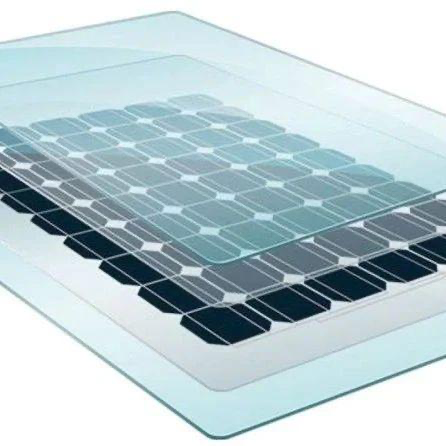

wave pattern glass. This makes the wave pattern glass an ideal choice for lighting fixtures, such as table lamps or pendant lights. The soft glow emitted by these fixtures will create a cozy and relaxing ambiance in any room.Photovoltaic modules with ultra-white glass

Glass curtain wall is a non-combustible material, but in the face of fire, it can melt or soften, in the fire only a short time will occur glass broken, so in the architectural design to fully consider the fire requirements of the building

In bathrooms and bedrooms, for instance, frosted glass doors or windows allow natural light to filter in, creating a bright and airy atmosphere without compromising privacy In bathrooms and bedrooms, for instance, frosted glass doors or windows allow natural light to filter in, creating a bright and airy atmosphere without compromising privacy

In bathrooms and bedrooms, for instance, frosted glass doors or windows allow natural light to filter in, creating a bright and airy atmosphere without compromising privacy In bathrooms and bedrooms, for instance, frosted glass doors or windows allow natural light to filter in, creating a bright and airy atmosphere without compromising privacy opaque frosted glass.

opaque frosted glass.Photovoltaic glass definition and classification

With the continuous aging of the main materials and main components of the curtain wall, if it is not checked and maintained in time, it will form a larger security risk.

Mauro, a former inventor, is now a professor of engineering and materials science at Pennsylvania State University. He has been fascinated by glass since he visited the Corning Museum of Glass in New York at the age of 6. He recalled being fascinated by the colors and shapes. Today, he knows more about the function of glass than almost anyone, but he remains in awe of the substance. Glass is a unique thing, he said. It breaks the mold.

It offers practical benefits such as UV protection and sound insulation, making it a desirable choice for environments that require tranquility amid chaos It offers practical benefits such as UV protection and sound insulation, making it a desirable choice for environments that require tranquility amid chaos

It offers practical benefits such as UV protection and sound insulation, making it a desirable choice for environments that require tranquility amid chaos It offers practical benefits such as UV protection and sound insulation, making it a desirable choice for environments that require tranquility amid chaos tinted black glass. In cars, this glass ensures a driver's comfort by reducing glare and heat, enhancing the driving experience with a touch of class.

tinted black glass. In cars, this glass ensures a driver's comfort by reducing glare and heat, enhancing the driving experience with a touch of class.The Craftsmanship Behind Real Silver Mirrors

Finding the Perfect Glass for Sale A Comprehensive Guide

Conclusion

Historically, mirrors date back to ancient civilizations, where polished metal surfaces such as bronze and silver were used to reflect images. However, these early mirrors had limitations in terms of clarity and fidelity. The development of the surface silvered mirror in the 19th century marked a turning point. By applying a thin layer of metallic silver to the back of a sheet of glass, inventors created a product that not only enhanced reflectivity but also protected the silver from tarnishing. This innovation led to mirrors that were clearer and more effective than their predecessors, revolutionizing everything from personal grooming to artistic representation.

2. Aesthetic Appeal Frosted glass offers a modern and sleek appearance that can enhance the design of any space. Its elegant finish can complement various decor styles, from minimalist to contemporary, making it a versatile option for both new builds and renovations.