Types of Natural Gas Filters

Types of Natural Gas Filters

The fundamental operation of a pressure reducer is relatively straightforward yet highly effective. It typically consists of a diaphragm, spring mechanism, and an inlet and outlet connection. When pressurized fluid enters the reducer, it acts on the diaphragm, which is connected to a spring. The balance between the spring tension and the fluid pressure dictates the output pressure. As the output pressure increases, the diaphragm moves, compressing the spring until a steady-state is achieved. This mechanism allows the pressure reducer to automatically adjust and maintain the set output pressure despite fluctuations in the input pressure.

Gas pressure reducers are indispensable tools that ensure safety and efficiency across multiple industries. By controlling and stabilizing gas pressure, they protect equipment, optimize performance, and maintain safety standards. As technology advances, the design and functionality of these devices continue to evolve, making them even more effective and adaptable to the diverse needs of various applications. Understanding the importance and operation of gas pressure reducers is essential for professionals across fields who rely on gas systems in their operations.

Gas Pressure Regulator An Essential Component for Safe and Efficient Gas Management

4. Double-Pipe Heat Exchangers The simplest design consists of one pipe inside another, with one fluid circulating through the inner pipe and another through the outer pipe. They are easy to design and manufacture, making them suitable for small-scale applications.

While pressure reducing valves are designed to require minimal maintenance, regular checks are essential to ensure their proper functioning. Common issues include leaks, which can occur at the valve seat or due to diaphragm damage. Additionally, if the outlet pressure is not stable, it may indicate a malfunction or wear in internal components, necessitating inspection or replacement.

2. Equipment Protection In any gas processing system, maintaining the integrity of equipment is crucial. Gas coalescer filters protect compressors, turbines, and other equipment from damage caused by contaminants. By filtering out harmful substances, these filters extend the lifespan of critical machinery and reduce maintenance costs.

Gas valves are used across various industries, including utilities, manufacturing, and residential sectors. In residential applications, gas valves control the supply of natural gas to stoves, heaters, and other appliances, ensuring that these devices operate efficiently and safely. In manufacturing, gas valves regulate the flow of gases used in processes such as welding, heating, and power generation.

Gas pressure vessels are indispensable in modern society, facilitating the safe storage and transportation of gases necessary for various applications. Understanding the significance of these vessels, along with the regulations and standards that govern their use, is vital for ensuring safety and efficiency in industries ranging from healthcare to manufacturing. As technologies advance, the design and materials used in gas pressure vessels continue to evolve, promising even greater safety and performance in the future.

Gas measurement is vital for multiple reasons. Firstly, it ensures safety in environments where flammable or toxic gases are present. Industrial facilities, laboratories, and confined spaces require real-time monitoring to prevent accidents and protect workers. Secondly, accurate gas measurements facilitate compliance with environmental regulations. Industries are often required to monitor emissions and ensure they do not exceed permissible limits. Thirdly, gas measurement plays a crucial role in optimizing processes and enhancing operational efficiency. By measuring gases involved in chemical reactions, businesses can adjust parameters to improve yields and reduce waste.

- Maintenance and Longevity Many gas heat exchangers are designed for easy maintenance and can offer a long operational life with minimal degradation.

Moreover, gas metering plays a significant role in the broader context of energy efficiency and environmental conservation. With accurate measurements, gas utilities can optimize their delivery systems, reducing waste and minimizing emissions associated with gas distribution. Furthermore, by encouraging consumers to adopt energy-efficient practices through detailed consumption data, gas metering indirectly contributes to lower carbon footprints.

Gas systems play a crucial role in various industries, ranging from residential heating to large-scale manufacturing processes. One of the most essential components of these systems is the gas pressure regulator. This device is designed to maintain a constant output pressure regardless of fluctuations in input pressure, ensuring the safe and efficient use of gas.

4. Electronic Pressure Regulators Utilizing electronic controls, these regulators enable more advanced monitoring and adjustments, ideal for automated and high-tech applications.

- Industrial Manufacturing Many manufacturing processes require precise pressure levels for optimal performance. PRVs are integral to controlling pressures in pneumatic systems, hydraulic systems, and process equipment.

The fundamental function of a gas safety valve is straightforward it acts as a fail-safe mechanism. When system pressure reaches a critical threshold, the valve automatically opens, allowing excess gas to escape safely into the atmosphere or into a designated venting system. This process not only relieves pressure but also prevents potential explosions or ruptures in the gas containment systems.

1. Directional Control Valves These valves determine the path that the compressed air takes. They can switch the air's direction, allowing for the operation of actuators in various positions. Common configurations include 2/2, 3/2, and 5/2 valves, indicating the number of ports and positions.

Maintenance and Best Practices

Conclusion

- Manual Shut-Off Valves Operated by hand, these valves often feature levers or wheels that regulate flow. Users must manually close or open these valves as required.

Given the potential hazards associated with high-pressure gases, safety is of utmost importance in the design and operation of gas pressure vessels. Adequate safety measures must be incorporated to prevent accidents such as explosions or leaks. Regular inspections and maintenance routines are essential to identify any signs of wear, corrosion, or structural weaknesses.

5. Maintenance and Monitoring Properly maintained PRVs can provide many years of reliable service. Regular inspections and monitoring of pressure settings are crucial to ensure they are functioning correctly. Some advanced PRVs offer remote monitoring capabilities, allowing operators to track pressure levels in real time and make adjustments as needed.

They help to track the flow of products in and out of the facility, as well as monitor stock levels to ensure that there are enough products on hand to fulfill customer orders They help to track the flow of products in and out of the facility, as well as monitor stock levels to ensure that there are enough products on hand to fulfill customer orders

They help to track the flow of products in and out of the facility, as well as monitor stock levels to ensure that there are enough products on hand to fulfill customer orders They help to track the flow of products in and out of the facility, as well as monitor stock levels to ensure that there are enough products on hand to fulfill customer orders distribution station.

distribution station.Natural gas is a vital energy source that powers homes, industries, and vehicles across the globe. However, to ensure its safe and efficient use, the pressure of natural gas must be regulated during transport and distribution. This is where pressure-reducing valves (PRVs) come into play. A natural gas pressure-reducing valve is an essential component in the gas supply system that controls the pressure of the gas flowing from high-pressure pipelines to lower pressure systems required for end-use applications.

In addition to safety, PRVs contribute to the efficiency of a system. By maintaining optimal pressure conditions, they minimize energy consumption and reduce the wear and tear on pumps and other equipment. This not only prolongs the life of the machinery but also reduces maintenance costs, leading to significant savings over time.

The design of gas pressure vessels involves rigorous engineering principles

. Several factors are considered when creating these vesselsTypes of Pneumatic Valves

Conclusion

The Mechanism of Action

Air control valves are devices specifically designed to control the direction, flow, and pressure of compressed air within a pneumatic system. These valves can be found in various applications, from simple tools to complex manufacturing machinery. They are essential for automating processes, enhancing safety, and ensuring equipment operates at optimal performance.

One of the key benefits of using gas pressure reducers is that they help to prevent damage to equipment and avoid safety hazards that can arise from high-pressure gas. By reducing the pressure of the gas to a safe and manageable level, these devices help to protect valves, pipes, and other components from being damaged or even destroyed. This not only helps to prolong the lifespan of equipment but also reduces the risk of accidents and potential harm to personnel.

Types of Shut-Off Valves

Maintenance Tips

Visual Appeal

1. Cost-Effective Solution One of the most appealing aspects of roll shingles is their affordability. The price per square foot is significantly lower compared to traditional shingle types. This makes them an attractive option for homeowners and contractors looking to minimize costs without compromising quality.

1. Weather Exposure Constant exposure to harsh weather conditions—such as rain, wind, and hail—can accelerate the wear on granules.

1. Manufacturing Defects Unfortunately, sometimes shingles come off the production line with defects. If the adhesive used to bond the granules is of poor quality or improperly applied, the granules may detach more easily than they should. Homeowners should always purchase shingles from reputable manufacturers and retailers to minimize this risk.

Durability is a significant factor in any roofing decision. Black asphalt shingles are known for their resilience, typically lasting 20 to 30 years with proper maintenance. They can withstand harsh weather conditions, including heavy rain, strong winds, and snow. Most black asphalt shingles are treated with materials that enhance their resistance to algae and moss growth, which can be an issue in humid climates. Regular inspections and maintenance can further extend the life of the roof, making black asphalt shingles a reliable option for homeowners looking for longevity.

Before diving into the installation process, it's essential to understand what architectural shingles and 3-tab shingles are. Architectural shingles, also known as dimensional shingles, offer a three-dimensional look with varied thicknesses and shapes, giving roofs a more textured appearance. In contrast, 3-tab shingles are flat and uniform, leading to a traditional look. While 3-tab shingles have been standard for many years, architectural shingles provide better wind resistance and longevity.

Environmental Benefits

5. Slate Shingles Among the most durable options, slate shingles can last over 100 years with proper maintenance. They are ideal for certain architectural styles but are significantly more expensive than other types of roofing.

In conclusion, 3% tab green shingles present a winning combination of aesthetic appeal, durability, energy efficiency, and cost-effectiveness. Whether you are replacing an old roof or constructing a new home, these shingles provide an excellent choice that enhances both the beauty and functionality of your property. With their environmentally friendly advantages, homeowners can feel good about their choice, knowing they are contributing positively to the environment while enjoying the practical benefits of quality roofing. Investing in 3% tab green shingles is a decision that can keep your home stylish and secure for years to come.

- Local Building Codes Before making a final decision, ensure that the selected shingles comply with local building regulations. This is especially important in areas prone to severe weather.

In summary, replacement roof granules are more than just decorative; they are essential to the overall performance and longevity of your roofing system. By understanding their importance and addressing issues of granule loss promptly, homeowners can protect their investments and ensure the safety and comfort of their homes. If you suspect that your roof’s granules are deteriorating, it’s time to consult with a roofing professional to assess the condition and take necessary actions to maintain your roof’s integrity.

Aesthetic Appeal and Value

One of the primary challenges of installing asphalt shingles in winter is the impact of low temperatures on both the shingles and the installation process. Asphalt shingles are made from a mixture of asphalt and fiberglass, which can become brittle in cold weather. This brittleness can make shingles more prone to cracking and breaking during installation. Moreover, cold temperatures can affect the adhesive properties of the shingle sealants, leading to potential issues with sealing and overall roof performance.

Historical Significance

3. Improved Wind Resistance Many premium shingles are rated to endure winds of up to 130 mph or more. This feature not only enhances the longevity of the roof but also provides peace of mind for homeowners living in storm-prone areas.

Energy Efficiency

Despite being a synthetic product, fiberglass shake shingles are crafted to replicate the natural beauty of wood. They come in a variety of colors and textures, allowing them to seamlessly blend with different architectural styles, from rustic cabins to modern homes. This versatility ensures that homeowners do not have to compromise on visual appeal when choosing a durable roofing option.

In the world of construction and architecture, the choice of roofing materials can significantly influence the durability, aesthetic appeal, and overall functionality of a building. Among various materials, slab roof tiles have emerged as a preferred option for many homeowners and builders. These tiles, characterized by their flat design and robust construction, provide a plethora of advantages that cater to diverse architectural needs.

Conclusion

Environmental Considerations

Durability and Longevity

In the world of roofing, aesthetics and functionality go hand in hand, and one of the most visually striking and durable options available today is the metal barrel tile roof. This roofing style combines the timeless elegance of traditional barrel tiles with the modern advantages of metal materials, making it an increasingly popular choice among homeowners and builders alike.

Iron roof tiles, often made from galvanized or coated steel, offer remarkable durability. Unlike traditional roofing materials like asphalt shingles or clay tiles, iron is resistant to extreme weather conditions, including heavy rain, snow, and high winds. Its resilience greatly reduces the risk of damage, which can lead to costly repairs or replacements. Many manufacturers offer warranties that can extend up to 50 years, underscoring the long-term value that iron roofing provides.

Formation and Characteristics

Architectural shingles offer numerous advantages that contribute to their rising popularity

Three-tab shingles offer a compelling combination of affordability, accessibility, and functionality for homeowners in need of a new roof. By understanding the factors that influence pricing and considering the total cost of the roofing project, homeowners can make informed decisions that align with their budget and long-term goals. Whether you are replacing an existing roof or installing a new one, three-tab shingles remain a reliable option that delivers value without breaking the bank.

Installation Process

Moreover, the smooth surface of the double Roman half tile is easily maintainable, while its durability ensures longevity. When paired with the right color palette, these tiles can enhance the elegance of a room, providing a timeless appeal that does not easily fade with changing trends.

Advantages of Aluminum Tile Metal Roofing

1. Material Costs Asphalt shingles, known for their affordability and versatility, typically range from $90 to $100 per square. Higher-end options, such as architectural shingles, may cost between $100 and $150 per square.

In an era where energy conservation is more crucial than ever, steel roof tiles also shine in their efficiency. Many steel roofing options are manufactured with reflective coatings that can help minimize heat absorption. This property keeps homes cooler in the summer, leading to reduced air conditioning costs. Additionally, certain steel roof tiles can be integrated with insulation materials, further enhancing a home’s energy efficiency. This not only benefits homeowners’ wallets but also serves the environment by reducing energy consumption.

Conclusion

Cost-Effective Solution

On average, composite shingles typically last between 25 to 50 years, depending on various factors including the quality of the shingles, the installation process, and the environmental conditions where the house is located. Higher-quality composite shingles, often referred to as premium shingles, tend to have a longer lifespan, sometimes exceeding 50 years. This extended longevity is primarily due to the thicker materials and enhanced manufacturing processes that offer more resistance to wear and tear.

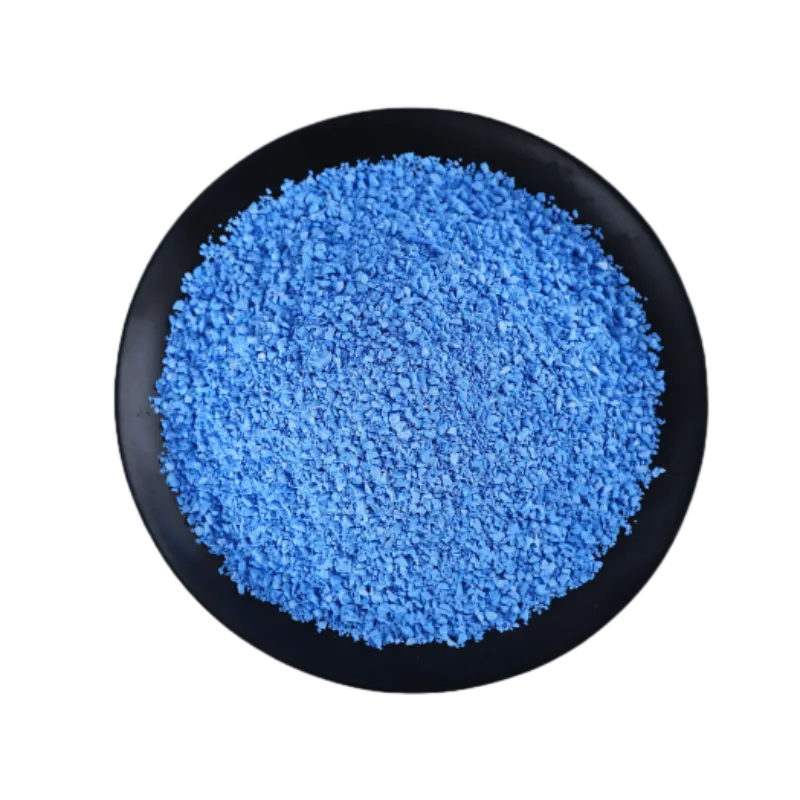

In recent years, the conversation around climate change and energy efficiency has gained significant traction. One innovative solution that has emerged on the roofing scene is the use of cool roof granules. As urban areas continue to grow, so does the “urban heat island” effect, where cities become significantly warmer than surrounding rural areas due to human activities. Cool roof granules play a vital role in addressing this phenomenon by reflecting more sunlight and absorbing less heat, ultimately contributing to a cooler environment.

Asphalt shingles have long been a popular roofing material for residential and commercial buildings due to their durability, affordability, and aesthetic appeal. When it comes to choosing the right shingles for your roofing project, selecting a reputable supplier is crucial. This article explores the key aspects of asphalt shingles suppliers, focusing on their offerings, qualities to consider, and tips on making informed choices.

Laying Down the Shingles

Aesthetic Appeal

In conclusion, steel roof tiles offer a fantastic combination of durability, energy efficiency, aesthetic versatility, and sustainability. As homeowners look for long-lasting roofing solutions that also enhance the value and beauty of their homes, steel roof tiles emerge as a compelling option. With their many advantages, investing in steel roof tiles can be one of the smartest decisions a homeowner makes, ultimately leading to a roof that not only protects but also elevates the home’s overall appeal. For those considering a new roof, exploring steel roof tiles for sale may very well lead to the perfect choice for enduring elegance and functionality.

In conclusion, the price of clay tiles can vary based on several factors including material quality, manufacturing processes, size, brand reputation, market dynamics, location, and installation costs. For anyone considering clay tiles for their next project, understanding these influences can assist in making smarter purchasing choices. Whether you are looking to enhance the beauty of your home or invest in a durable roofing solution, knowing the ins and outs of clay tile pricing can help you achieve both aesthetic and financial goals.

While traditional slates are primarily made from stone, terracotta slates offer a similar aesthetic with the added benefits of clay. Terracotta roof slates are thinner and lighter than regular clay tiles, making them easier to handle and install. Their smooth, flat surface provides an elegant finish, ideal for both residential and commercial buildings. The widespread use of terracotta slates has grown due to their affordability compared to natural stone slates, while still offering significant durability and a classic appearance.

1. Fiberglass Shingles As the name suggests, fiberglass shingles contain a fiberglass mat coated with asphalt and granules. They are lighter than traditional asphalt shingles and offer superior resistance to fire and moisture. This type of shingle is particularly popular in areas prone to wildfires due to its non-combustible properties.

- Research Look for local roofing companies with positive reviews and testimonials. Online platforms can provide valuable insights into the experiences of past clients.

1. Cost-Effective Installation One of the most significant advantages of installing steel roofing over asphalt shingles is the cost savings associated with not having to remove the existing shingles. Roof removal can be labor-intensive and costly, leading to higher overall project expenses. By layering the steel on top, homeowners can save on labor and disposal costs.

One of the standout advantages of architectural shingles is their aesthetic appeal. The multi-dimensional layering creates a shadow effect that enhances the roof's visual profile. Available in a wide range of colors, textures, and styles, these shingles can complement various architectural designs, from contemporary to traditional homes.

Furthermore, the texture of clay tiles adds depth and intrigue to rooftops, catching light in various ways throughout the day. This dynamic attribute enables homeowners to create an inviting and sophisticated ambiance, often drawing admiration from passersby and enhancing curb appeal.

Durability and Longevity