Gas metering is especially important in industries that rely heavily on natural gas for their operations, such as manufacturing and energy production

Moreover, gas regulators come in different types and designs, tailored to suit specific applications. For example, low-pressure regulators are typically used in residential settings, while high-pressure regulators serve industrial processes. Some regulators are designed for specific gas types, such as propane or natural gas, ensuring compatibility with the system they serve. Innovations in regulator technology, such as electronic pressure regulation, offer enhanced precision and adaptability for modern automated systems.

As the world continues to search for sustainable energy solutions, the role of natural gas in the energy mix remains significant. Pressure reducing stations are critical components in this equation, facilitating the safe and efficient distribution of natural gas from high-pressure transmission lines to end-users. By understanding their operation and importance, we can appreciate these unsung heroes of the energy infrastructure, ensuring that natural gas remains a reliable energy source for the future.

Applications of Pressure Regulating Devices

Gas distribution stations are fundamental components of the energy supply chain, ensuring that natural gas reaches consumers safely and efficiently. As we move towards a more sustainable energy future, these stations will likely adapt and evolve, embracing new technologies and alternative gases to meet the changing demands of society. Their role in energy distribution will remain critical as we navigate the complex landscape of energy consumption and environmental responsibility.

How Gas Safety Valves Work

The Concept of Al-Muthabit Exploring the Foundations of Certainty

The Importance of Air Control Valves in Modern Industries

How Gas Regulators Work

4. Cost-Effectiveness While the initial investment in gas coalescer filters may seem substantial, their long-term benefits outweigh the costs. By preventing equipment degradation and improving operational efficiency, these filters contribute to lower overall expenditure on maintenance and repairs.

1. Gate Valves These valves are primarily used for on/off control, featuring a gate that moves up and down to open or close the flow path. They are ideal for applications where minimal resistance to flow is necessary when the valve is fully open.

Community engagement is another important aspect of natural gas distribution stations. These facilities often operate within neighborhoods, and maintaining a positive relationship with the local community is essential. Transparency regarding operations, safety measures, and environmental impact can build trust with residents, fostering a collaborative approach to energy distribution.

Types of Regulating Valves

3. Operational Efficiency By maintaining optimal pressure levels, these valves contribute to the overall efficiency of gas systems. They allow processes to run smoothly without interruptions caused by pressure anomalies.

In conclusion, the concept of NG transcends mere technological advancement; it embodies a holistic transformation of our society. By embracing Next Generation technologies, we can create a more connected, efficient, and inclusive world. The potential for positive change is immense, but it requires a collective effort to address the challenges that accompany such rapid evolution. As we stand at the brink of this new era, the choices we make today will shape the future, guiding us toward a realm where the possibilities are limitless. Embracing NG is not just about innovation; it is about envisioning a better tomorrow for all.

- Energy Sector Natural gas is often stored in large pressure vessels before being distributed through pipelines. These vessels play a crucial role in energy storage and management.

How Do They Work?

4. Versatility Gas boosters can be tailored for various gases, accommodating diverse industry needs. This adaptability makes them essential for a range of applications.

1. First-stage Regulators These are found in gas distribution systems and reduce the pressure from the transmission pipeline to an intermediate level.

1. Globe Valves These are widely used for flow regulation due to their excellent throttling capabilities. Their design features a linear flow path, allowing for precise control over the flow rate.

2. Thickness and Dimensions The wall thickness of the vessel is directly related to the pressure it will contain. Engineers must calculate the necessary thickness using formulas derived from the material's yield strength and the operational pressures expected.

Despite its benefits, the extraction and transportation of natural gas pose environmental challenges. Hydraulic fracturing, or fracking, has made it possible to tap into previously inaccessible gas reserves, but it raises concerns about water contamination and seismic activity. Therefore, it is imperative that the industry adopts best practices and regulatory measures to minimize environmental impact while meeting the growing demand for energy.

In the rapidly evolving landscape of our modern economy, the significance of business organizations cannot be overstated. These entities serve as the backbone of economic growth, innovation, and employment. A business organization can take various forms—such as sole proprietorships, partnerships, corporations, and cooperatives—each having its unique structure, advantages, and challenges.

3. Electric Globe Valves These valves are designed for throttling service, providing fine control over fluid flow. They are commonly used in applications where flow regulation is essential.

- Vertical Filter Separators These are cylindrical vessels that allow gas to flow upwards while settling liquids at the bottom

. They are widely used for their simplicity and efficiency.Another significant aspect of pneumatic control valves is their reliability and durability. Unlike hydraulic systems, which can suffer from leaks and require extensive maintenance, pneumatic systems are often easier to maintain and less prone to failure. The materials used in the construction of these valves are designed to withstand the rigors of industrial environments, ensuring a long service life with minimal downtime. Additionally, pneumatic systems operate at lower pressure levels than hydraulic ones, making them safer in many applications.

Understanding Electric Heaters The Efficient Solution for Home Heating

- Efficiency Regulating pressure helps maintain the operational efficiency of gas appliances. When appliances function within the designed pressure range, they work more efficiently, leading to cost savings on energy bills.

Gas regulators are found in various settings, including

3. Pressure Relief Valves These valves are crucial for protecting systems from overpressure conditions. They automatically vent excess pressure, preventing damage to pneumatic equipment.

4. Non-return PRVs These valves not only reduce pressure but also prevent backflow, making them essential in applications like compressed air systems.

1. Improved Performance By minimizing data volume, coalescing filters significantly enhance the performance of data processing systems. With less data to handle, databases can respond faster, and applications can operate more smoothly.

Despite its potential, gasification technology faces several challenges. High capital costs, technology maturation, and the need for more efficient feedstock preparation are significant hurdles that must be addressed. Moreover, public awareness and acceptance of gasification, especially when it involves municipal solid waste, vary widely.

In conclusion, natural gas filters play a crucial role in ensuring the quality, safety, and efficiency of natural gas as an energy source. As the world increasingly moves toward cleaner energy solutions, the importance of effective filtration technologies will only grow. By investing in and implementing advanced filtration systems, the natural gas industry can not only meet regulatory requirements but also contribute significantly to the sustainable energy goals of the future.

Yes, a cast iron skillet can be taken directly from the stovetop to the oven and vice versa. It can withstand high heat for an extended time and retain that heat for long periods, making it great for use as a serving vessel.

Be sure to dry the skillet thoroughly with a clean towel to prevent rusting Be sure to dry the skillet thoroughly with a clean towel to prevent rusting

Be sure to dry the skillet thoroughly with a clean towel to prevent rusting Be sure to dry the skillet thoroughly with a clean towel to prevent rusting cleaning cast iron skillet with salt. You can also place the skillet on a stovetop burner on low heat to evaporate any remaining moisture.

cleaning cast iron skillet with salt. You can also place the skillet on a stovetop burner on low heat to evaporate any remaining moisture.

When making eggs or pancakes, you’re more likely to use a frying pan than a stockpot. You can fry various foods at high temperatures using a frying pan, as its name suggests.

Restaurant Dining: Sizzling steak plates and platters are a popular choice in restaurants, where they are used to present sizzling entrees directly to the table, creating a memorable and visually striking dining experience for patrons.

Not all pans are the same, however, and sometimes how your food turns out depends on what type of pan you use. Read on to see some of the most common types of frying pans and what they're used for.

Their ability to retain heat allows for a beautiful caramelization of ingredients, perfect for creating mouth-watering dishes with a crispy crust Their ability to retain heat allows for a beautiful caramelization of ingredients, perfect for creating mouth-watering dishes with a crispy crust

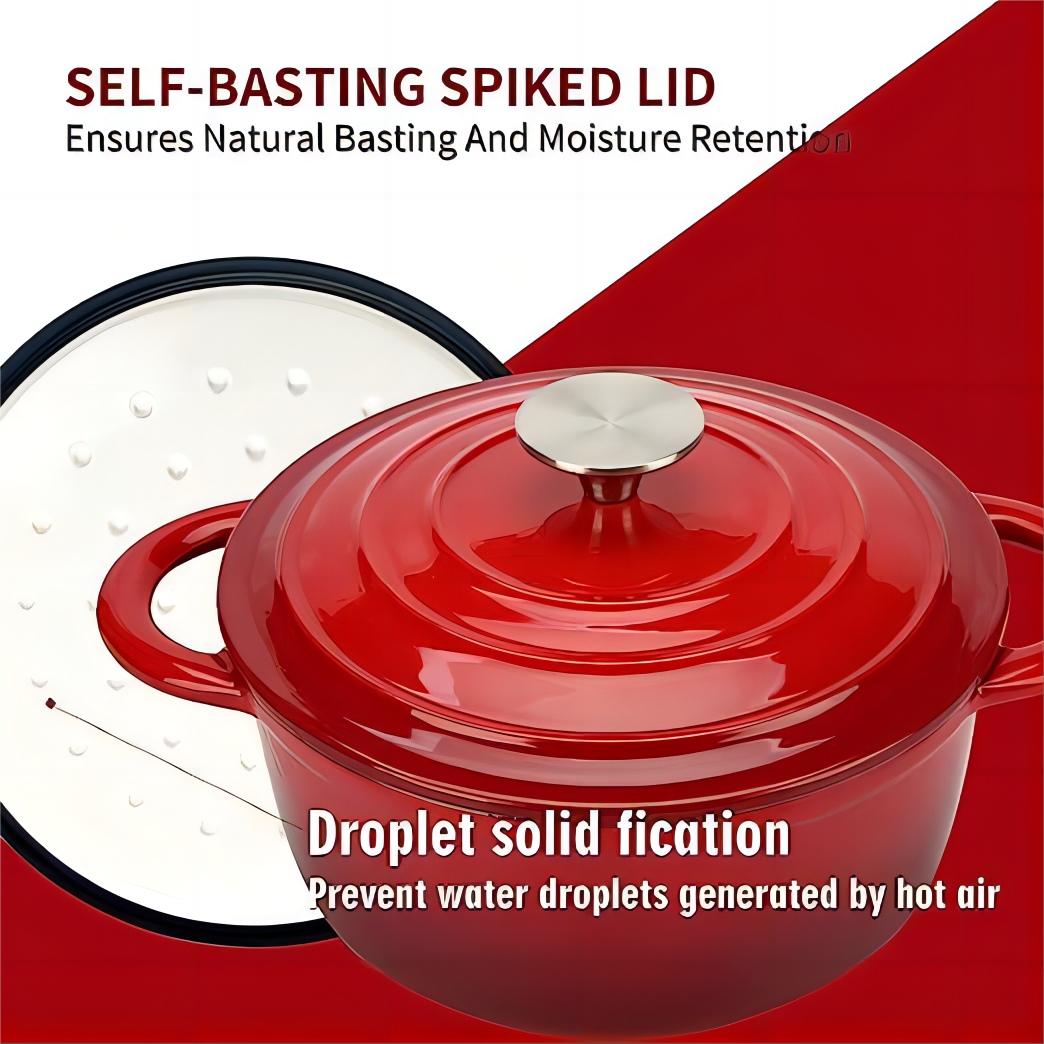

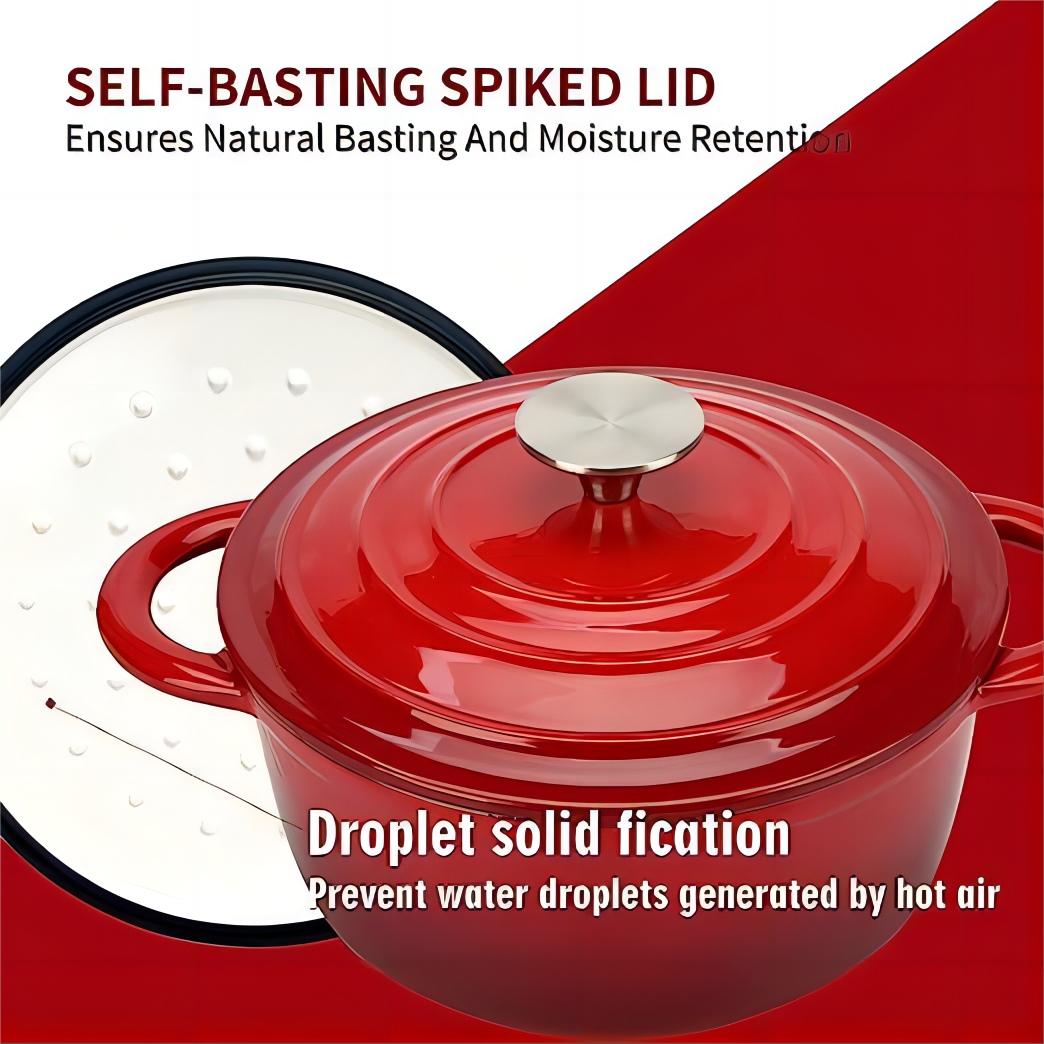

Their ability to retain heat allows for a beautiful caramelization of ingredients, perfect for creating mouth-watering dishes with a crispy crust Their ability to retain heat allows for a beautiful caramelization of ingredients, perfect for creating mouth-watering dishes with a crispy crust enameled cast iron skillet.

enameled cast iron skillet.Size is an important factor to consider when choosing the right enamel pot. For those looking for a small enamel pot, there are many options suitable for single or small servings. These smaller enameled pots are great for cooking soups, sauces, and side dishes. They're also great for reheating leftovers or making a quick meal for one person.

Proper use and storage of enamel cookware is also key to maintaining its quality. Avoid air-firing enamel pot at high temperatures to avoid damaging the enamel surface. When storing enamel cast iron pots for sale, it’s a good idea to wrap it in a soft cloth or paper towel to prevent scratches or bumps.

They have excellent heat conductivity and distribute heat evenly, making them suitable for a wide range of cooking methods They have excellent heat conductivity and distribute heat evenly, making them suitable for a wide range of cooking methods

They have excellent heat conductivity and distribute heat evenly, making them suitable for a wide range of cooking methods They have excellent heat conductivity and distribute heat evenly, making them suitable for a wide range of cooking methods dutch oven types. However, carbon steel Dutch ovens require seasoning before use to prevent rust and ensure that food does not stick to the pot.

dutch oven types. However, carbon steel Dutch ovens require seasoning before use to prevent rust and ensure that food does not stick to the pot.Skillets are the heavier option because of its thickness, the material used to craft it, and larger size. This extra weight allows skillets to distribute heat evenly and retain heat better, making it ideal for recipes that involve searing and braising.