.

The versatility of pressure regulators makes them indispensable in numerous industries. Here are a few key applications

In addition to safety, PRVs contribute to the efficiency of a system. By maintaining optimal pressure conditions, they minimize energy consumption and reduce the wear and tear on pumps and other equipment. This not only prolongs the life of the machinery but also reduces maintenance costs, leading to significant savings over time.

In political arenas, the influence of high-pressure advocacy organizations is evident in their ability to mobilize public opinion and drive policy changes. These organizations often employ strategies that leverage social media and grassroots campaigns to exert pressure on policymakers, demonstrating the power of collective action in high-pressure situations.

2. Pressure Regulators These are typically used in commercial and industrial applications. They maintain the pressure of the gas at a consistent level, ensuring that large-scale systems run efficiently while preventing fluctuations that could lead to equipment damage.

Decompression skids are predominantly used in the oil and gas industry, where they are integral to the safe and efficient extraction, processing, and transportation of hydrocarbons. As oil and gas are often found under immense pressure deep within the earth, decompression skids are essential for managing the transition of these substances from high-pressure environments to surface operations. This not only prevents hazardous incidents such as blowouts but also ensures a smoother operation flow, aligning with the industry's commitment to safety and sustainability.

The significance of natural gas safety valves cannot be overstated

. They serve several critical functions

Despite its advantages, the LNG industry also faces several challenges. The initial investment for liquefaction plants and infrastructure is substantial. Additionally, fluctuating natural gas prices can deter investment and create uncertainty in the market. Environmental concerns regarding the fracking process used to extract natural gas can lead to public opposition and regulatory hurdles.

A typical PRV consists of several key components the inlet and outlet ports, a diaphragm, a spring, and an adjustment knob or screw. The diaphragm is crucial as it senses pressure changes; when the downstream pressure rises above the set point, the diaphragm compresses the spring to close the valve partially, restricting the flow of gas. Conversely, if the downstream pressure falls below the set point, the spring expands, opening the valve to allow more gas flow.

Gas valves play a crucial role in managing the flow and pressure of gases in various applications, ranging from industrial processes to residential heating systems. They serve as essential components that ensure safety, control, and efficiency in gas distribution systems. Understanding the types, functions, and maintenance of gas valves can help users make informed decisions, thereby enhancing safety and operational efficacy in their respective environments.

What is a Gas Pressure Regulator?

1. Natural Gas Distribution In natural gas utilities, pressure regulators are essential for delivering gas safely to residential and commercial customers. The gas enters at high pressure from the main supply line and must be reduced to a suitable level for use in appliances and heating systems.

Applications of Gas Heat Exchangers

The Concept of Fasel in Everyday Life

Coalescing filters are indispensable in modern industrial applications, offering a robust solution for separating liquids from gases and other liquids. Their wide-ranging applications across different sectors underscore their versatility and importance. As industries continue to evolve and innovate, the demand for efficient and effective filtration solutions, such as coalescing filters, is bound to grow. Understanding and leveraging this technology will be crucial for maintaining competitiveness and sustainability in an increasingly complex industrial landscape.

Despite their importance, regulators face significant challenges. One of the most pressing issues is the often-constrained nature of regulatory agencies, which may lack the necessary funding, staffing, or authority to effectively carry out their mandates. This can lead to weakened enforcement and oversight, especially in industries where rapid change outpaces regulatory frameworks. Additionally, the global nature of business today complicates regulatory efforts, as issues such as cross-border transactions and international compliance raise questions about coordination among different regulatory bodies.

Gas pressure reducers have a wide range of applications across different sectors. In the medical field, for instance, oxygen pressure regulators are crucial for supplying patients with the correct amount of oxygen at a safe pressure. Similarly, in the welding industry, gas regulators are used to control the pressure of welding gases, ensuring optimal performance and safety during operations.

Additionally, some stations incorporate safety mechanisms such as excess flow valves, which can close off gas supply if the flow rate exceeds a predetermined limit, as a response to pipe ruptures or major leaks. This feature is crucial for minimizing the risk of explosions and other dangerous incidents.

3. Flow Control Valves These valves adjust the speed of the actuators by controlling the flow rate of air. Often used in conjunction with directional control valves, they help fine-tune the performance of pneumatic cylinders or motors.

The future of natural gas filtration appears promising as technological advancements continue to evolve. Research and development efforts are focusing on creating more efficient filter materials and designs that offer higher filtration performance, longer lifespan, and lower maintenance requirements. Innovations such as nanotechnology and smart filtration systems are emerging, providing enhanced capabilities to monitor and adapt to varying conditions in real time.

Furthermore, coalescing filters can decrease maintenance costs. By preventing water-related issues, such as corrosion and microbial growth, these filters extend the life of components like fuel injectors and pumps. Consequently, enterprises can avoid costly repairs and downtime, leading to increased productivity.

Design and Construction

In industrial environments, where large volumes of gas are used, pressure regulators are critical for maintaining safety and operational efficiency. They are employed in processes such as welding, chemicals manufacturing, and food processing, where precise gas flow and pressure are vital for quality control and safety standards.

Moreover, the quality of natural gas directly influences the performance of end-use applications, such as power generation, heating, and industrial processes. Clean gas has higher calorific value, leading to better energy output and reduced emissions. As such, the natural gas industry is increasingly prioritizing filtration strategies to maintain gas quality and meet the demands of a sustainable energy future.

In conclusion, electric water heaters offer a highly effective solution for heating water in residential settings. With various sizes and types available, homeowners can select an option that best meets their needs, whether they prioritize upfront costs, long-term efficiency, or environmental impact. As technology continues to advance, electric water heaters will likely become even more efficient, ensuring they remain a popular choice in homes around the world.

3. Excess Flow Valves These valves detect and respond to sudden surges in gas flow, which may indicate a rupture in the line. They automatically close to prevent further gas from escaping into the environment.

How Gas Safety Valves Work

One of the most common types of gas heat exchangers is the tubular heat exchanger. This design features a series of tubes through which one fluid flows, while the other fluid flows around or outside these tubes. The large surface area provided by the tubes allows for effective heat transfer. Another popular design is the plate heat exchanger, where thin plates create channels for the fluids. These plates enhance heat transfer efficiency due to their large surface area and close proximity of the fluids.

Natural gas pressure reducers are essential components of modern gas distribution systems. Their ability to safely and efficiently regulate gas pressure makes them invaluable in residential, commercial, and industrial settings. As the demand for natural gas continues to rise, the importance of these devices will only grow. Investing in high-quality pressure reducers and regular maintenance can ensure optimal performance, safety, and compliance in utilizing natural gas, highlighting the critical role they play in the energy landscape. Whether you are a homeowner or an industry professional, understanding and utilizing natural gas pressure reducers is vital for harnessing the full potential of natural gas as a reliable energy source.

Regular maintenance of gas regulators is essential for ensuring their proper performance. Homeowners and businesses should schedule periodic inspections by qualified professionals. Common maintenance tasks include checking for leaks, ensuring that the regulator is free from corrosion, and confirming that all components are functioning correctly.

Gas pressure regulators are utilized across a wide range of industries, including healthcare, manufacturing, energy, and construction. In the healthcare industry, for example, regulators are crucial in ensuring that medical gases such as oxygen are delivered at safe and effective pressures to patients. In manufacturing and energy sectors, regulators help in optimizing the performance of equipment and preventing hazardous situations.

3. Activated Carbon Filters These filters are particularly effective in removing odorants and volatile organic compounds (VOCs) from natural gas. They employ activated carbon to adsorb unwanted chemicals, ensuring a cleaner product.

Cleaning and Storage: After use, it is important to clean and dry the bacon press or steak weight thoroughly to prevent rusting. Proper storage in a dry environment and occasional re-seasoning will help maintain the quality of the cast iron over time.

There is often confusion when comparing saute pans, fry pans, and French skillets. A French skillet can be described as a combination of a saute pan and a frying pan.

Skillets and frying pans are basically the same types of pan. When it comes time to create a delicious meal, you want the right cooking instrument for the job. Skillets are great for shallow sauces and searing meat, while saute pans can hold a large volume of ingredients. In the end, it is your kitchen and your choice - cook with whatever you want. However, using the right pan for your recipe ensures that you will have a smoother time making those delectable at-home meals.

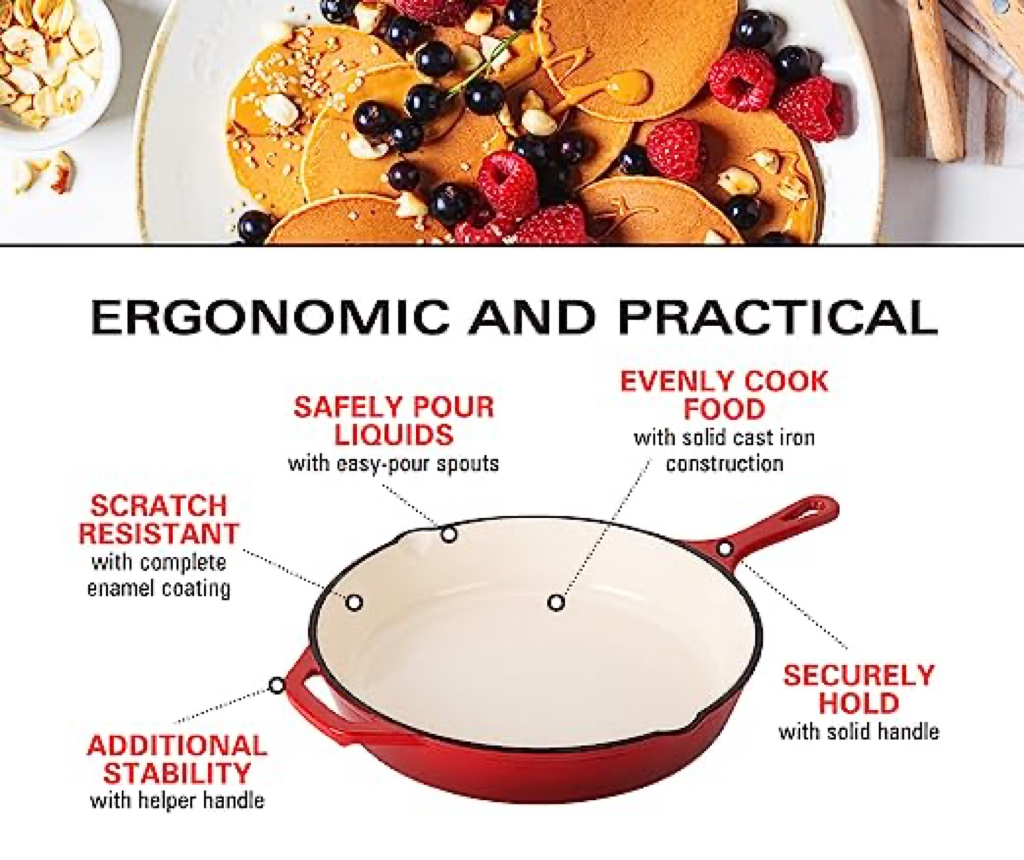

While they are more resistant to acidic foods that can sometimes react with bare cast iron, it's still essential to handle them with care to avoid chipping or cracking the enamel While they are more resistant to acidic foods that can sometimes react with bare cast iron, it's still essential to handle them with care to avoid chipping or cracking the enamel

While they are more resistant to acidic foods that can sometimes react with bare cast iron, it's still essential to handle them with care to avoid chipping or cracking the enamel While they are more resistant to acidic foods that can sometimes react with bare cast iron, it's still essential to handle them with care to avoid chipping or cracking the enamel enameled cast iron skillet set. A gentle hand wash and occasional reseasoning can keep these skillets in top condition for years to come.

enameled cast iron skillet set. A gentle hand wash and occasional reseasoning can keep these skillets in top condition for years to come. It should be avoided to use soap and water immediately after cooking, as this can strip away the seasoning It should be avoided to use soap and water immediately after cooking, as this can strip away the seasoning

It should be avoided to use soap and water immediately after cooking, as this can strip away the seasoning It should be avoided to use soap and water immediately after cooking, as this can strip away the seasoning cast iron shallow fry pan. Instead, a simple scrub with a stiff brush and hot water, perhaps while the pan is still warm, is usually sufficient. After cleaning, it is essential to dry the pan thoroughly and apply a thin layer of oil to protect the seasoning before storing it.

cast iron shallow fry pan. Instead, a simple scrub with a stiff brush and hot water, perhaps while the pan is still warm, is usually sufficient. After cleaning, it is essential to dry the pan thoroughly and apply a thin layer of oil to protect the seasoning before storing it. mini cast iron grill pan. It requires seasoning, which involves coating the pan with oil and heating it to create a non-stick surface. With proper care, your pan will develop a natural patina over time, enhancing its non-stick properties and durability.

mini cast iron grill pan. It requires seasoning, which involves coating the pan with oil and heating it to create a non-stick surface. With proper care, your pan will develop a natural patina over time, enhancing its non-stick properties and durability.In conclusion, black cast iron griddles and grill pans offer versatile cooking options for a wide range of culinary creations. Whether used in home kitchens or professional settings, these culinary tools enhance cooking techniques, impart unique flavors, and create visually appealing dishes, making them valuable additions to any culinary repertoire.

Non-stick pans have some form of an interior coating such as Teflon or PTFE which prevents food from sticking during cooking. They're best for foods like pancakes, eggs, fish, or crepes which require low or medium heat and little or no oil. This makes them ideal for weight management because you can use them to cook low-fat food.

The details: While cast-iron frying pans are very familiar, home cooks typically know less about carbon steel pans. But they have all the advantages of cast iron and several more: They’re lighter, heat up faster and more evenly, and can cook a wider variety of foods. That’s why they’re the go-to pan in many restaurant kitchens. If you’ve ever eaten at a steakhouse, your meat was probably seared in a carbon steel frying pan.

One of the most obvious differences between skillets and frypans is its shape. But it is also a factor that often confuses people, simply because they’re both flat-bottomed rounded pans with a handle. Here’s how they differ in regards to shape.

All in all, whether you choose a set with a lid, a single skillet with a lid, a Cast Iron Skillet With a Removable Handle, or a Cast Iron Skillet With a Wooden Handle, a cast iron skillet is a must-have for any cooking enthusiast. Cast iron skillet versatility, durability, and heat retention make it a valuable tool for a variety of culinary creations.

Most of these pans have a long handle, making it easy to move the pan on and off the stove. However, larger frying pans may include a smaller grab handle to carry the weight.