.

A gas pressure vessel operates on fundamental physical principles. When gas is contained within a vessel, it exhibits pressure due to its molecular motion. This pressure increases with temperature and decreases with increasing volume, as described by the ideal gas law (PV = nRT). Therefore, the design of these vessels must consider both the pressure exerted by the gas and the temperature under which the gas is stored.

Distribution Stations The Backbone of Modern Supply Chains

The working principle of a gas pressure regulator valve can be broken down into a few key components the inlet pressure, outlet pressure, and the regulating mechanism. When gas enters the regulator, it encounters a diaphragm that responds to the pressure differences. If the inlet pressure exceeds the desired outlet pressure, the diaphragm moves to close off the gas flow. Conversely, when the outlet pressure drops below the set point, the diaphragm opens to allow more gas in.

2. Thickness and Dimensions The wall thickness of the vessel is directly related to the pressure it will contain. Engineers must calculate the necessary thickness using formulas derived from the material's yield strength and the operational pressures expected.

A pressure regulating skid typically consists of several key components pressure regulators, valves, gauges, piping, and sometimes additional automation systems for monitoring and control. These elements work in concert to maintain the desired pressure throughout the transport system, preventing pressure spikes that could lead to equipment damage or safety hazards.

- Oil and Gas Regulating valves help manage flow and pressure in pipelines, refineries, and processing plants, ensuring safe and efficient operations.

Natural gas valves are mechanical devices designed to control the flow of gas in pipelines and other systems. They are used to manage and regulate the pressure and volume of gas being transported, ensuring that it reaches its destination safely and efficiently. Valves can be found in various configurations, including gate valves, ball valves, globe valves, and butterfly valves, each providing unique advantages depending on the application.

In the ongoing pursuit of sustainable energy solutions, gasification has emerged as a significant technological advancement. A gasifier is a device that converts organic or fossil-based materials into carbon monoxide, hydrogen, and carbon dioxide through a process known as gasification. This process occurs in a low-oxygen environment, enabling the transformation of materials such as biomass, coal, or waste into syngas (synthesis gas), which can be used for various applications, including electricity generation, heating, and as a feedstock for producing chemicals and fuels.

Importance of Gas Metering

- Oil and Gas In this sector, pressure vessels are used to store crude oil, natural gas, and other hydrocarbons. They play a crucial role in refining processes and transportation.

One of the primary reasons for investing in an air purifier is the increasing incidence of respiratory illnesses. According to the World Health Organization, air pollution is a significant risk factor for respiratory diseases such as asthma and chronic obstructive pulmonary disease (COPD). By using an air purifier, individuals can decrease their exposure to allergens and pollutants, ultimately reducing the likelihood of developing these health issues. This is especially vital for vulnerable populations, such as children, the elderly, and those with pre-existing health conditions.

Types of Pressure Regulators

Additionally, many gas distribution companies are exploring partnerships with renewable energy firms to create hybrid systems that can efficiently manage both traditional natural gas and greener alternatives. This transition will not only help reduce carbon footprints but also ensure energy security in the face of fluctuating demand and supply challenges.

The Importance of Gas Pressure Reducers

2. Safety With built-in features like pressure relief and regulation, these valves help maintain safe operating conditions. This is critical in environments where malfunction could lead to catastrophic failures.

The Power of NG Embracing the Next Generation of Technology

The set pressure can be adjusted on the valve itself, allowing for flexibility depending on the needs of the system. This adaptability makes PRVs crucial for various applications, including residential gas supplies, commercial settings, and industrial operations.

1. Tank Water Heaters These are the traditional water heaters that store a significant amount of hot water in a tank, usually ranging from 20 to 80 gallons. They heat the water continuously and keep it warm so that it is readily available whenever needed. While they are generally more affordable, they take up more space and can lead to higher energy bills due to heat loss.

The significance of pressure relief valves cannot be overstated. They play an essential role in safeguarding equipment such as boilers, pressure vessels, pipelines, and tanks. Without them, these systems are at risk of experiencing ruptures, explosions, or other disastrous failures due to uncontrolled pressure buildup.

Understanding Gas Heat Exchangers Principles and Applications

In conclusion, natural gas distribution stations are integral to the efficient and safe delivery of natural gas to consumers. They ensure the proper regulation of pressure, maintain the quality of the gas supplied, and implement robust safety measures. As the world continues to prioritize sustainability, these facilities are evolving to incorporate renewable alternatives into their operations. The future of energy distribution lies in the ability to adapt and innovate, and natural gas distribution stations are at the forefront of this transformation, playing a crucial role in the energy landscape of tomorrow.

2. Two-stage Regulators These regulators are more complex and are typically used in high-pressure applications. They consist of two distinct stages the first stage reduces the high incoming pressure to an intermediate level, while the second stage further lowers it to the desired output pressure. Two-stage regulators offer greater stability and are ideal for applications requiring precise pressure control.

Importance of Gas Pressure Reducing Valves

In addition to the design, several factors influence the efficiency of gas heat exchangers, including surface area, flow arrangement, and the properties of the gases involved. Engineers often optimize these factors to enhance performance and ensure effective energy transfer.

1. Tank Water Heaters These are the traditional water heaters that store a significant amount of hot water in a tank, usually ranging from 20 to 80 gallons. They heat the water continuously and keep it warm so that it is readily available whenever needed. While they are generally more affordable, they take up more space and can lead to higher energy bills due to heat loss.

On the other hand, electronic or smart gas meters represent the latest advancements in gas metering technology. These meters not only measure gas consumption but also have the capability to transmit data wirelessly. This allows utilities to remotely monitor consumption patterns, perform diagnostics, and even detect leaks more efficiently. Smart meters enhance transparency for consumers by providing detailed insights into their consumption habits, allowing them to manage their energy use better.

Logistics and transportation also see the utilization of vehicle-mounted equipment, particularly in the realm of delivery and freight services. Trucks can be equipped with refrigeration units for perishable goods, loading ramps for heavy equipment, or even automated sorting systems. These enhancements allow delivery services to be more efficient and cost-effective, meeting the demands of a rapidly growing e-commerce market. Vehicle-mounted technology ensures that shipments are delivered on time and in optimal condition, which is essential in today’s competitive landscape.

Another important category is the gas-phase filter, which targets gaseous pollutants such as volatile organic compounds (VOCs), sulfur dioxide (SO₂), and nitrogen oxides (NOₓ). These substances pose significant health risks and contribute to the phenomena of smog and acid rain. Chemical sorbents, such as activated carbon, zeolites, and silica gels, are commonly used in gas-phase filters to adsorb or react with these harmful gases, thus preventing them from entering the atmosphere.

There are several types of gas heat exchangers, each designed for specific applications. The two most common types are air-to-air heat exchangers and air-to-water heat exchangers.

Overall, plaster corner angles are a simple yet essential element in any construction project. From protecting corners to enhancing aesthetics and improving acoustics, these angles play a key role in shaping the look and feel of a space. By investing in high-quality plaster corner angles and ensuring proper installation, builders and designers can create visually stunning and structurally sound interiors that stand the test of time.

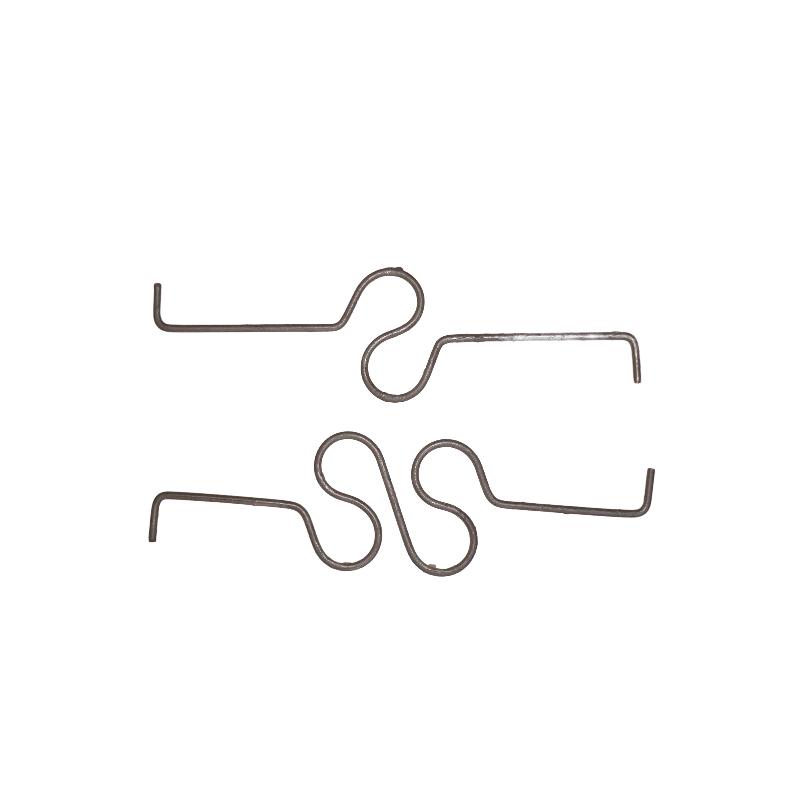

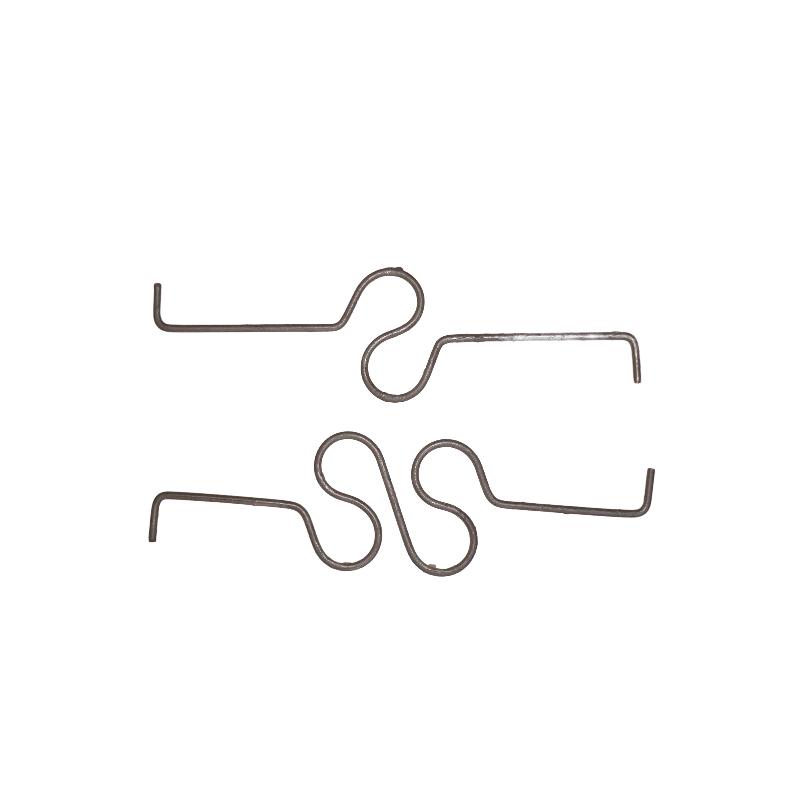

Horizontal joint reinforcement, masonry joint reinforcement, and brick reinforcement ladders are essential techniques for ensuring the structural integrity and durability of masonry constructions. These reinforcement methods play a critical role in preventing cracks, distributing loads evenly, and enhancing the overall stability of masonry walls. By incorporating these techniques into their projects, builders can create safer, more resilient structures that stand the test of time. Understanding and utilizing these reinforcement strategies is crucial for achieving high-quality masonry construction.

Additionally, the fence can be electrified or combined with other materials like wooden posts for added strength and aesthetic appeal Additionally, the fence can be electrified or combined with other materials like wooden posts for added strength and aesthetic appeal

Additionally, the fence can be electrified or combined with other materials like wooden posts for added strength and aesthetic appeal Additionally, the fence can be electrified or combined with other materials like wooden posts for added strength and aesthetic appeal welded wire fence 6ft.

welded wire fence 6ft. This type of fencing uses a low-voltage electric shock to deter animals from trying to breach the barrier This type of fencing uses a low-voltage electric shock to deter animals from trying to breach the barrier

This type of fencing uses a low-voltage electric shock to deter animals from trying to breach the barrier This type of fencing uses a low-voltage electric shock to deter animals from trying to breach the barrier types of field fencing. Electric fencing is highly effective and relatively easy to install, but it does require regular maintenance to ensure that it remains in good working order.

types of field fencing. Electric fencing is highly effective and relatively easy to install, but it does require regular maintenance to ensure that it remains in good working order.

Galvanized iron wire is extensively used in creating fencing and animal enclosures on farms. Its high tensile strength ensures that fences are robust enough to withstand the pressures exerted by livestock, keeping animals securely contained. The zinc coating on the wire prevents rust, even in outdoor conditions, ensuring that the fences remain durable and effective over long periods. Farmers use this wire to build various types of fencing, including barbed wire fences, which provide an additional layer of security. The longevity and low maintenance of galvanized iron wire fences make them a cost-effective solution for protecting crops from wildlife and securing livestock.