Gas pressure reduction stations consist of various components, including pressure control valves, regulators, filters, and relief valves

Understanding Pressure Reduction Devices Importance and Applications

The effectiveness of gas filtration largely depends on the type of filtration technology employed

. Common techniques include mechanical filtration, adsorption, and chemical scrubbing. Mechanical filtration, which is the simplest form, uses physical barriers such as filters or screens to capture larger particles from the gas stream. While this method is effective for particulate matter, it may not adequately remove gaseous pollutants, necessitating the use of additional technologies.

Conclusion

By reducing the pressure of the gas to an appropriate level, gas pressure reduction stations ensure that the gas can be safely and efficiently used in a variety of applications. For example, residential appliances such as stoves, water heaters, and furnaces require low-pressure gas to operate effectively. Gas pressure reduction stations play a critical role in providing a reliable and consistent supply of natural gas to homes and businesses.

Understanding Natural Gas Pressure Regulators

Modern gasification systems consist of several key components gasifiers, feeding systems, cooling and cleaning systems, and gas utilization units. The gasifier, the core of the equipment, provides the necessary conditions for gasification to occur. Typically, this involves high temperatures (between 700°C and 1,200°C), controlled levels of oxygen, and steam. Various types of gasifiers exist, including fixed-bed, fluidized-bed, and entrained-flow gasifiers, each with its advantages and suitability for specific feedstocks and applications.

Moreover, effective communication plays a vital role in the success of high-pressure organizations. In these fast-paced environments, the ability to share information quickly and clearly can mean the difference between success and failure. Team members must be trained to communicate succinctly and assertively, ensuring that critical information is relayed efficiently. The establishment of clear channels for communication is crucial, as it minimizes the chances of misunderstandings and facilitates better teamwork.

Natural Gas Valve A Crucial Component in Energy Systems

When the outlet pressure exceeds a preset level, the diaphragm moves to close the valve slightly, reducing the flow of gas. Conversely, if the outlet pressure drops below the desired level, the diaphragm will open the valve wider, allowing more gas to flow in. This self-regulating mechanism ensures that the pressure remains stable, adjusting to varying demands.

Effective gasification depends on various equipment components, each playing a crucial role in the overall process. Key components include

In conclusion, the candidate for gas presents both opportunities and challenges in the global energy landscape. As nations strive to achieve their climate targets and transition to a cleaner energy future, natural gas can play a critical role as a transitional energy source. However, addressing methane emissions, ensuring energy security, and engaging the public are essential components of harnessing the potential of natural gas effectively. Through concerted efforts and innovations, natural gas can contribute positively to a balanced and sustainable energy future, paving the way for a cleaner, greener planet.

Shut-off valves are crucial components in various industrial applications, serving a fundamental role in the control and regulation of fluid flow. These valves are designed to either completely stop or allow the passage of liquids and gases within a system. Their functionality is not only vital for operational efficiency but also for ensuring safety and environmental protection.

4. Process Control Regulators allow for greater control over processes, resulting in improved product quality and consistency.

Despite their benefits, blood pressure regulating devices are not without challenges. Accuracy can vary between devices, so it’s essential for users to choose reliable models that have been validated for accuracy. Furthermore, patient education is crucial; users must understand how to use these devices correctly to avoid misinterpretation of results.

In the ever-growing field of natural gas utilization, the importance of valves cannot be overlooked. As the world increasingly turns to natural gas as a clean and efficient energy source, ensuring the reliability and safety of its distribution is paramount. Natural gas valves are at the forefront of this effort, providing the necessary control and safety measures that protect both infrastructure and human life. Efforts to innovate and improve valve technology will continue to be essential as we move toward a more sustainable energy future, ensuring that natural gas remains a vital part of our global energy landscape.

The geopolitical implications of natural gas cannot be overlooked either. Natural gas reserves are concentrated in specific regions, leading to strategic partnerships and power dynamics among countries. For instance, nations that are rich in natural gas, such as the United States and Qatar, can leverage their resources to gain geopolitical influence. Consequently, securing natural gas supplies has become a central theme in international relations, often driving foreign policy decisions.

Gasification is a thermal process that transforms carbonaceous materials, such as coal, biomass, or municipal solid waste, into syngas through the application of heat and controlled amounts of oxygen or steam. The syngas—a mixture primarily consisting of hydrogen, carbon monoxide, and some carbon dioxide—serves as a versatile energy carrier. This innovative process not only aids in waste management but also plays a significant role in transitioning towards a renewable energy landscape.

3. Operational Efficiency The presence of water and particulates in gas streams can significantly hinder operational efficiency. Gas coalescer filters allow for uninterrupted gas flow, minimizing downtime and enhancing the overall productivity of gas processing operations.

In terms of construction materials, shut-off valves can be made from a variety of substances, including brass, stainless steel, plastic, and cast iron, each differing in terms of durability, corrosion resistance, and temperature tolerance. For example, stainless steel valves are preferred in industries dealing with corrosive substances due to their high resistance to rust and chemical damage. Consequently, engineers must consider the application environment when selecting materials to ensure longevity and optimal performance.

Conclusion

Applications Across Industries

3. System Longevity Proper pressure management through the use of reducers can extend the lifespan of equipment. High-pressure gases can cause wear and tear on valves, pipes, and other components. By controlling pressure, reducers minimize stress on these parts, leading to decreased maintenance needs and increased reliability.

In addition to reducing the pressure of the gas, gas pressure reduction stations may also incorporate equipment for measuring and monitoring the flow and quality of the gas. This data is essential for ensuring the safe and efficient operation of the natural gas distribution system. By monitoring key parameters such as pressure, temperature, and flow rate, operators can quickly identify any issues or abnormalities and take corrective action as needed.

Maintenance of natural gas regulators is essential to ensure their reliable operation. Regular inspections can help identify wear and tear, buildup of debris, or other issues that could impede performance. Homeowners and businesses should work with qualified professionals to conduct these inspections, ensuring that any potential problems are addressed promptly.

Conclusion

The filtration component serves to entrain solid particles, debris, and other impurities that may exist within the fluid. These contaminants can range from dirt and rust to more complex materials like wax and polymers. The separator aspect, on the other hand, is responsible for distinguishing between different phases of the mixture—commonly oil, water, and gas—allowing for the effective removal of undesired components.

- Size Assess the hot water needs of your household. A larger family may require a tank heater with sufficient capacity, whereas a smaller household might benefit from a tankless unit.

Components of Gasification Equipment

Pressure reduction stations, often referred to as PRS, are strategically located along gas pipelines. Their primary function is to reduce the high pressure of natural gas—often exceeding 1,000 psi—down to safer levels, typically around 10 to 60 psi, that are suitable for household usage. This pressure reduction is achieved through a combination of mechanical and equipment methodologies, including pressure regulators, control valves, and safety devices.

Gas pressure regulators are essential devices used in various industries and applications, ensuring the safe and efficient use of gases. As a crucial component in gas distribution systems, they are designed to control and stabilize the pressure of gases throughout the system. This article will examine the function, types, and significance of gas pressure regulators in modern applications.

Natural gas, as an essential energy source, has been gaining increasing attention in recent years due to its numerous benefits and advantages. With its clean burning properties and abundance, natural gas has become a popular choice for various applications, ranging from residential heating to industrial production. In this article, we will explore the reasons behind the growing popularity of natural gas and its potential as a primary energy source.

5. Customizability Skid mounted units can often be customized to meet specific operational requirements. Businesses can tailor these systems to suit particular environments or production needs, ensuring optimal performance in diverse applications.

Training Aid

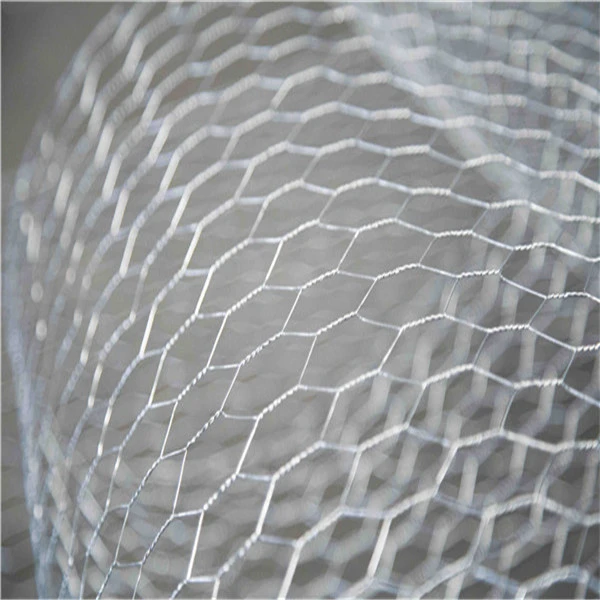

Another significant benefit of PVC poultry netting is its flexibility. This material can be easily cut and shaped to fit different areas of a farm, whether it’s a small backyard setup or a large commercial poultry operation. This adaptability allows farmers to create enclosures that are tailored to their specific needs, whether that includes protection against larger predators such as raccoons and foxes or simply to keep the birds confined within a designated area.

- Agricultural Settings Protecting livestock and crops from predators while still allowing visibility for monitoring. Mesh fencing can also be used to separate different farming areas.

1. Fencing Whether erecting a simple garden fence or something more elaborate, ground spike 4x4 posts provide the necessary support to keep the structure upright and secure.

Functionality and Boundaries

Enhanced Stability

Creating Atmosphere

5. Safety and Security In safety applications, this wire mesh can serve as a barrier in industrial facilities or public spaces. It provides a secure way to restrict access to areas where safety concerns are paramount, such as around machinery or hazardous sites.

Using a wire crate can have a positive impact on your dog’s behavior. Dogs, like humans, thrive on structure and routine. A crate can provide a sense of predictability that helps reduce anxiety and stress. When dogs know they have a designated space where they can relax, they are less likely to engage in destructive behaviors out of boredom or anxiety.

Understanding Chain Link Fencing

Additionally, the welded wire design ensures that the fence maintains its shape over time, resisting sagging and deformation. Many products feature galvanized steel, making them resistant to rust and corrosion, thus ensuring longevity. This is especially important in areas that experience harsh weather conditions, where exposure to moisture can quickly deteriorate other types of fencing.

1. Corrosion Resistance The zinc coating provides an excellent barrier against moisture and chemicals, significantly increasing the lifespan of the wire mesh in outdoor and harsh environments.

3. Cleaning Keeping the holders clean from debris and mold can prevent deterioration. A simple wash with soap and water, combined with thorough drying, can keep your wooden holders looking fresh.

Design and Functionality

Rigid wire fencing boasts several advantages that make it a preferred choice for many individuals and businesses

Razor barbed wire is a type of fencing material characterized by sharp blades or points that are attached to a wire strand. Unlike traditional barbed wire, which features simple barbs that may be less intimidating, razor barbed wire elevates the concept of deterrence through its design, which is engineered to pose a significant physical threat to would-be intruders. This fencing solution is widely used in high-security areas, including prisons, military bases, and industrial sites, but its applications extend to residential properties as well.

Ispirazioni di Design

3. Cost-Effectiveness When compared to traditional fencing solutions, steel wire mesh fences often provide a more cost-effective option, especially in large installations. Their durability reduces the long-term costs associated with repairs and replacements.

4. Brooding Areas In brooding situations where chicks need extra protection, poultry netting can help create a secure environment. It ensures that younger birds are shielded from larger livestock and potential predators.

Conclusion

Versatility in Application

Aesthetic Appeal

Creative Solutions

As of 2023, wire mesh costs generally range from $0.80 to $7.00 per square foot, depending on the factors outlined above. For instance, standard galvanized steel wire mesh may cost around $1.50 to $2.50 per square foot, whereas premium options such as stainless steel could exceed $5.00 per square foot. Purchasing in bulk often yields discounts, making it more economical for large projects.

1. Fencing Systems One of the most common applications for galvanized mesh clips is in the construction of fencing. Whether it's agricultural fencing, security fencing, or decorative garden fencing, mesh clips play a critical role in affixing wire mesh to fence posts. The combination of galvanized wire and mesh clips ensures that the fence can endure extreme weather conditions while preventing rust and corrosion.

Welded wire fencing consists of steel wires that have been electrically welded at their intersections, creating a sturdy and uniform mesh. The 25% refers to the percentage of material used in the production of the wire, indicating a balance between strength and affordability. This type of fence is known for its ability to withstand environmental stressors, making it an excellent option for various settings.

3. Low Maintenance Maintenance is often an overlooked aspect of fencing solutions. The welded nature of this fence means it’s less likely to sag or warp, significantly reducing the need for regular upkeep. Occasional cleaning to remove debris and checking for rust are typically all that’s required, making it a hassle-free option.

4. Installation Services Consider suppliers that provide installation services or at least guidance, ensuring that the fence is installed correctly for maximum effectiveness.

Benefits of Welded Wire Netting

Exploring the Benefits of Mesh Fences A Practical Solution for Various Needs

- Strength and Durability One of the primary benefits of 10 gauge welded wire is its strength. It can withstand significant pressure and is resistant to bending and breaking, making it a reliable option for various applications.

Conclusion

- Cost-Effective While the initial investment may be higher than some alternatives, the durability and low maintenance of galvanized PVC coated wire mesh reduce long-term costs associated with replacements and repairs.

4. Low Maintenance Unlike wooden fences that may require regular staining or painting, coated mesh fences are relatively low-maintenance. The protective coating prevents rust and corrosion, which means that periodic inspections and cleaning are usually all that is needed to keep the fence looking good and functioning properly.

Understanding Barbed Wire Fence Prices A Comprehensive Overview

1. Durability Steel is inherently a strong material, and when treated correctly, a steel wire mesh fence can last for decades. Whether exposed to harsh weather conditions or environmental factors, these fences remain resilient.

Secondly, consider the design and color of the fence. A well-chosen style can enhance the aesthetics of your yard while ensuring your chickens remain safe. Additionally, some vinyl fences come with added features such as lattice tops or decorative elements that can further elevate the appearance of your outdoor space.

Benefits of Wire Fencing

4. Shelving and Storage The mesh can also be used in the production of shelves and storage solutions. Its robustness supports weight while maintaining an open structure that allows for ventilation—ideal for storing items that need airflow.

BRC mesh is classified into various types based on the gauge of the wires used, their arrangement, and the specific applications they are designed for. Here are some common types

Another significant benefit is the ease of installation. Welded gabion baskets can be rapidly assembled on-site, reducing labor costs and project timelines. Furthermore, they can be stacked and arranged in countless configurations, offering design flexibility to suit specific project requirements.

3. Decorative Features Beyond their functional benefits, galvanised gabion boxes can be designed as visually appealing features in landscapes. They can be used as planters, seating arrangements, or decorative walls, adding texture and character to any garden or outdoor space. The natural aesthetic of stone and other fill materials can blend harmoniously with the surrounding landscape.

While the initial investment in a green plastic fence might be higher than wooden alternatives, the long-term savings are substantial. Given their durability and low maintenance requirements, homeowners can save money over time on repairs and replacements. Additionally, their ability to withstand environmental impact without fading or breaking means that they maintain their appearance longer, which is an attractive quality for any property owner.

In addition, 4x2 welded wire fences are frequently utilized in commercial settings, such as parks and recreational areas, where they can serve as protective barriers without obstructing views. They can also be used to delineate boundaries around construction sites, providing both security and safety.

- Fencing One of the most common uses is for fencing in residential, commercial, and agricultural settings. It provides secure boundaries for properties, gardens, and farms, keeping animals in and intruders out.

Before installing flat wrap razor wire fencing, it is essential to check local regulations and zoning laws, as some areas may have restrictions related to its use. Many jurisdictions recognize the need for security and allow the installation of such barriers, provided they comply with specific guidelines. Consulting with local authorities can ensure that the installation is both effective and lawful.

In industrial environments, welded wire mesh can function as safety barriers, shelving, and storage solutions. Its customizable dimensions allow manufacturers to produce mesh tailored to specific needs, whether it be for securing machinery or organizing inventory in warehouses.

5. Enkel rengöring Många täckta inhägnader är designade med tanke på enkelhet och funktionalitet. De flesta material är lätta att rengöra, vilket gör det enkelt att hålla en hygienisk miljö för ditt husdjur. Regelbunden rengöring är viktigt för att förhindra sjukdomar och hålla luften frisk.

5. Visibility and Airflow Unlike solid fences, chain link fences do not obstruct views, allowing you to maintain sightlines while securing your space. They also allow for airflow, which is beneficial in preventing damage from wind or snow buildup.