Definition and Overview

Definition and Overview

Another essential type of filter is the activated carbon filter, used primarily for removing gases such as hydrogen sulfide and carbon dioxide. Activated carbon has a porous structure that effectively adsorbs certain gases, cleaning the natural gas before it reaches consumers. This filtration process is particularly important in areas where natural gas fields are rich in sour gas (gas containing hydrogen sulfide), which can be hazardous if not treated adequately.

What is a Natural Gas Pressure Regulator?

Moreover, electric auxiliary heaters are generally easy to install and operate. Their straightforward design means that users do not require advanced technical knowledge to maintain them. Additionally, many modern systems come equipped with smart features, allowing homeowners and vehicle operators to control the heating remotely via smartphone applications.

Natural gas is one of the cleanest and most efficient fuels available today, used for heating, cooking, and generating electricity. However, like any other fuel, natural gas can be dangerous if not handled properly. This is where safety valves come into play, specifically designed to protect against any potential threats.

Applications of Gas Pressure Reducers

2. Regulating Valves As the name suggests, these valves are used to regulate the pressure and flow of air in a system. They ensure that the pneumatic pressure remains within desired limits, thus preventing damage to machinery and ensuring smooth operation.

Located in Medina, one of the holiest cities in Islam, Al-Madina Gateway Station plays a crucial role in facilitating the movement of millions of pilgrims who visit the city annually, especially during the Hajj season. The station is strategically positioned to provide easy access to the Prophet's Mosque, a masterpiece of Islamic architecture that attracts visitors from across the globe. This accessibility significantly enhances the experience for both locals and tourists, enabling them to engage more fully with the spiritual and historical significance of the area.

While pressure reducing valves are designed to require minimal maintenance, regular checks are essential to ensure their proper functioning. Common issues include leaks, which can occur at the valve seat or due to diaphragm damage. Additionally, if the outlet pressure is not stable, it may indicate a malfunction or wear in internal components, necessitating inspection or replacement.

However, while natural gas presents numerous benefits, it is not without challenges. One of the primary concerns is methane leakage during extraction and transportation. Methane is a potent greenhouse gas, with a global warming potential many times greater than CO2 over a shorter timeframe. Addressing leakage is crucial for ensuring that the shift to natural gas does not negate its environmental benefits. Advances in technology and stricter regulations can help minimize these emissions, ensuring that natural gas remains a cleaner alternative.

Hypertension Canada is a leading Canadian organization focused exclusively on hypertension. They provide clinical practice guidelines for healthcare providers to ensure effective management of hypertension in patients. Hypertension Canada also emphasizes the importance of self-monitoring blood pressure and provides resources for patients to take an active role in monitoring their health. Their awareness campaigns are instrumental in educating Canadians about the risks associated with uncontrolled blood pressure and encouraging regular check-ups.

Because of the inherent risks associated with pressure vessels, they are subject to stringent regulations and industry standards. Organizations such as the American Society of Mechanical Engineers (ASME) set guidelines for the design, construction, and maintenance of pressure vessels. Compliance with these standards not only ensures safety but also enhances the reliability and efficiency of the equipment.

In Technology

In conclusion, gas distribution stations are essential to our energy landscape. They ensure the safe, efficient, and reliable delivery of natural gas, playing a crucial role in energy accessibility, economic stability, and environmental sustainability. As we face the challenges of aging infrastructure and the transition to renewable energy, these stations will continue to evolve, ensuring a resilient energy future. The importance of maintaining and modernizing gas distribution systems cannot be overstated, as they remain a critical link in the chain of energy supply that underpins our modern society.

The concept of supercharging was popularized by Tesla, a pioneer in the electric vehicle market. Tesla's Supercharger network was launched in 2012, enabling its users to recharge their electric vehicles significantly faster than conventional charging stations. While a standard Level 2 charger may take several hours to recharge an EV, Tesla's superchargers can provide up to 80% charge in approximately 30 minutes for many models. This drastic reduction in charging time has been instrumental in bolstering consumer confidence in electric vehicles, as it allows drivers to take long road trips without the fear of running out of power.

Importance of Gas Pressure Regulating Valves

The natural gas market is characterized by a complex interplay of supply and demand, influenced by various factors such as geopolitical stability, economic growth, and technological advancements. The recent surge in shale gas production, particularly in the United States, has reshaped the global natural gas landscape, leading to increased competition and lower prices. This revolution has not only provided energy security for many nations but also contributed significantly to economic growth and job creation.

The safety and efficiency of a gas pressure reducing station heavily depend on regular maintenance routines and adherence to safety protocols. Inspections are routinely conducted to ensure all components are functioning correctly, with an emphasis on identifying wear and tear that could lead to failure. Operators must also be trained in emergency response procedures, ensuring that they can react swiftly in case of a mishap.

2. Plate Heat Exchangers Comprising multiple thin plates stacked together, this type efficiently transfers heat between two gases. They offer a high surface area for heat transfer, making them efficient and compact. Plate heat exchangers are often used in food processing and HVAC applications.

- Safety Electric water heaters eliminate the risks associated with gas leaks and ventilation issues, making them a safer option for many households.

The importance of safety valves can be illustrated through numerous historical accidents. The Bhopal disaster of 1984, often cited as one of the world's worst industrial disasters, underscores the catastrophic consequences of pressure control failures. In this incident, a combination of equipment malfunction and human error led to the release of toxic gas, resulting in thousands of deaths and long-term health effects. Properly functioning safety valves could have mitigated such an incident, highlighting the necessity for stringent safety measures in industrial settings.

4. Cost-Effectiveness Investing in the right type of shut-off valve can result in long-term savings by reducing the need for repairs, replacements, and operational inefficiencies.

Vaporizers are perhaps the most critical element of the regasification process. They employ different technologies, such as ambient air heating, seawater heating, or intermediate fluid heating to warm the LNG. The choice of vaporizer type often depends on the geographical location of the regasification terminal, the environmental conditions, and the volume of LNG being processed. For example, coastal facilities may utilize seawater vaporizers due to their availability, while inland facilities might rely on air or intermediate fluid systems.

Natural gas, primarily composed of methane, is found in underground reservoirs and must undergo a process to become liquefied. This liquefaction involves cooling the gas to approximately -162 degrees Celsius (-260 degrees Fahrenheit), at which point it transforms into a liquid state. The resulting LNG takes up about 1/600th of the volume of natural gas in its gaseous form, which makes it much more economical for storage and transportation, especially over long distances where pipelines are not feasible.

1. Precision Control Electric actuators provide high accuracy in flow regulation, which is essential in processes that require exact fluid measurement, such as chemical dosing or temperature control.

The Nature of High-Pressure Organizations

2. Gasifier The gasifier is the core reactor where the actual gasification takes place. Various gasifier designs exist, including fixed-bed, fluidized-bed, and entrained-flow gasifiers. Each design has its advantages and is selected based on the type of feedstock, the desired end products, and operational conditions. In this unit, feedstock is subjected to high temperatures (usually between 700°C to 1500°C) in the presence of limited oxygen, triggering thermochemical reactions that convert it into syngas.

Moreover, business organizations are vital in fostering competition. A competitive business environment often leads to better quality products and services, lower prices for consumers, and more choices in the marketplace. This competition can stimulate innovation, as companies strive to differentiate themselves and attract customers. Consequently, businesses invest in research and development, leading to technological advancements that can enhance productivity and efficiency across various sectors.

For instance, gate valves are typically used to start or stop the gas flow completely, while globe valves provide more precise flow control. Ball valves, known for their reliability and ease of use, are often employed in applications that require quick shut-off capabilities. Safety valves, on the other hand, are essential for protecting equipment by relieving excess pressure and preventing potential hazards.

Function of Pressure Reducing Regulators

Moreover, the use of decompression skids enhances operational efficiency. By ensuring that the decompression process occurs in a controlled environment, operators can minimize downtime and optimize resource extraction. This is particularly important in offshore platforms, where limited access to repair and maintenance can lead to significant production losses if equipment fails.

As supercharger technology continues to evolve, there are still challenges to address. The rollout of supercharging infrastructure must keep pace with the growing number of electric vehicles on the road. Additionally, ensuring compatibility between different electric vehicle brands and charging systems is vital for creating an inclusive charging network that benefits all users.

- Oil and Gas Production In upstream applications, these filters are essential for separating water and other impurities from raw gas before further processing or transportation.

The coalescing filter operates on the principle of separating two immiscible liquids—commonly water and fuel. At the heart of the filter is a media that promotes the coalescence of smaller water droplets into larger ones. When a fuel or oil mixture enters the filter, the hydrophobic (water-repelling) fibers of the filter media capture the water droplets. As these droplets collide with one another, they merge to form larger droplets that can then be drained from the system. This process effectively diminishes the water content in the fuel, thereby ensuring cleaner fuel is delivered to engines or machinery.

PRVs are widely used across various sectors, including water supply systems, HVAC installations, and industrial manufacturing processes. In municipal water systems, for instance, PRVs are critical for protecting pipes and fixtures from damage caused by excessive pressure. In HVAC systems, they maintain optimal pressure in heating and cooling circuits, enhancing system efficiency and comfort. Additionally, in the manufacturing sector, PRVs are often employed to ensure that machinery and equipment operate within specified pressure ranges, preventing potential failures and maintenance issues.

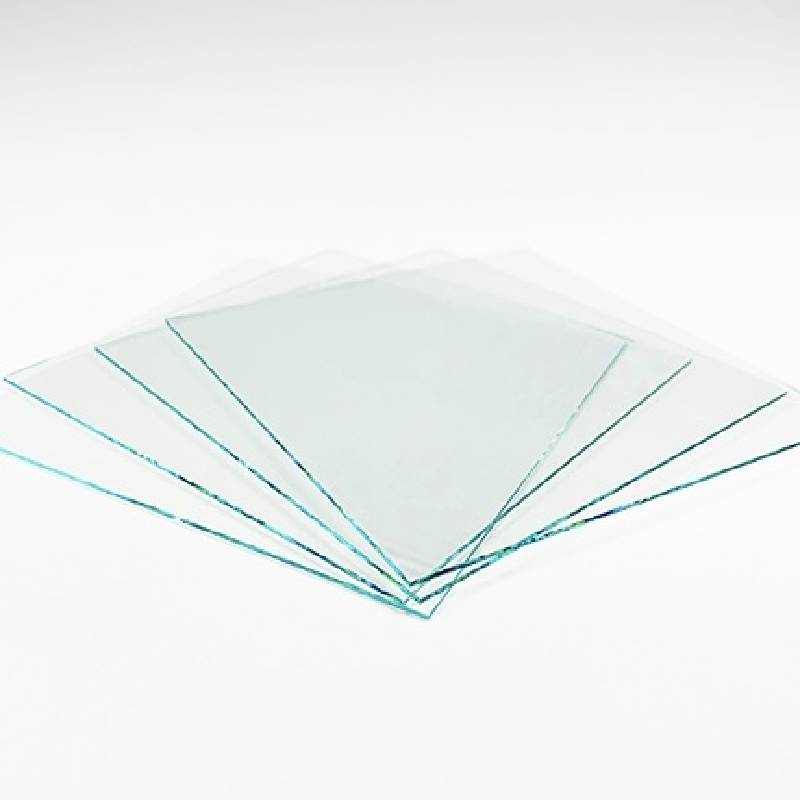

float glass plate. It serves us at dinner tables, in kitchens, and in art studios, bearing witness to the weight of food, the heat of ovens, and the scratch of artists' tools. Its strength lies not just in its composition but in its form—the even distribution of its mass creating a structure that can, surprisingly, withstand considerable pressure before it finally gives way.

float glass plate. It serves us at dinner tables, in kitchens, and in art studios, bearing witness to the weight of food, the heat of ovens, and the scratch of artists' tools. Its strength lies not just in its composition but in its form—the even distribution of its mass creating a structure that can, surprisingly, withstand considerable pressure before it finally gives way.Overall, custom acid etched glass is a versatile and practical option for adding a touch of sophistication to any space. Its customizable design options, practical benefits, and safety features make it a popular choice for designers and architects looking to create unique and stylish interiors. Whether used in residential homes, commercial buildings, or public spaces, acid etched glass is sure to make a statement and leave a lasting impression.

What is a Partially Silvered Mirror?

3. Display Cases and Retail Retail environments frequently employ 4mm float glass in display cases and shelving units, showcasing products while maintaining a clean and attractive presentation.

What is Float Glass Used For?

Its versatility also extends to color options, with a range of colors available to suit any taste and decor scheme Its versatility also extends to color options, with a range of colors available to suit any taste and decor scheme

Its versatility also extends to color options, with a range of colors available to suit any taste and decor scheme Its versatility also extends to color options, with a range of colors available to suit any taste and decor scheme milky frosted glass.

milky frosted glass.One of the main advantages of 2mm float glass is its thinness, which makes it ideal for use in applications where weight and space constraints are a concern. Its lightweight nature also makes it easy to handle and transport, which adds to its appeal in various industries.

Frosted glass cabinets with black accents can add a touch of elegance to a kitchen, while a black frosted glass shower door can create a luxurious spa-like atmosphere in a bathroom Frosted glass cabinets with black accents can add a touch of elegance to a kitchen, while a black frosted glass shower door can create a luxurious spa-like atmosphere in a bathroom

Frosted glass cabinets with black accents can add a touch of elegance to a kitchen, while a black frosted glass shower door can create a luxurious spa-like atmosphere in a bathroom Frosted glass cabinets with black accents can add a touch of elegance to a kitchen, while a black frosted glass shower door can create a luxurious spa-like atmosphere in a bathroom frosted glass black. The combination of frosted glass and black is also popular in modern furniture design, with pieces such as black metal and frosted glass coffee tables adding a touch of sophistication to any living room.

frosted glass black. The combination of frosted glass and black is also popular in modern furniture design, with pieces such as black metal and frosted glass coffee tables adding a touch of sophistication to any living room.In addition to glare reduction and energy efficiency, coated tinted float glass provides protection against harmful ultraviolet (UV) rays. Prolonged exposure to UV radiation can lead to skin damage and fading of interior furnishings, artwork, and flooring materials. Tinted float glass helps mitigate these effects by filtering out a significant percentage of UV rays, thereby protecting both individuals and their belongings. This feature is especially beneficial in spaces that experience a high amount of natural light, such as sunrooms, galleries, and retail displays.

low e plus glass. Perhaps the most significant advantage is its ability to reduce energy consumption. By lowering heating and cooling costs, Low-E glass can help to lower utility bills and reduce greenhouse gas emissions.

low e plus glass. Perhaps the most significant advantage is its ability to reduce energy consumption. By lowering heating and cooling costs, Low-E glass can help to lower utility bills and reduce greenhouse gas emissions.It is this hidden microscopic behavior of glass that makes glass such a curious vessel of beauty, which runs counter to everything we were taught as children about the state of matter. What we usually come into contact with is that matter has three states: solid, liquid, and gas. This is not unusual in any fanciful imagination. Still, glass is special.

One of the key factors that influence the price of blue reflective glass is the quality of the materials used in its production. Higher quality materials will result in a more durable and visually appealing glass with a higher price tag. The manufacturing process also plays a significant role in determining the price, as precision and attention to detail are required to achieve the desired reflective finish.

Opting for patterned glass cut to size is a decision that marries aesthetics with practicality. By providing an extensive array of designs and customizable dimensions, this glass offers flexibility that caters to diverse needs. As interior design continues to evolve, the integration of patterned glass solutions will undoubtedly play a pivotal role in shaping modern spaces. Whether revamping a home or designing a commercial space, choosing patterned glass is a commitment to quality, style, and sustainability, a perfect blend for any project.

In the contemporary design landscape, materials play a pivotal role in shaping not only aesthetics but also functionality. Among these materials, tinted black glass has emerged as a popular choice, embodying a striking blend of elegance, privacy, and practicality. This article delves into the multifaceted appeal of tinted black glass, exploring its applications, benefits, and the unique atmosphere it creates in various settings.