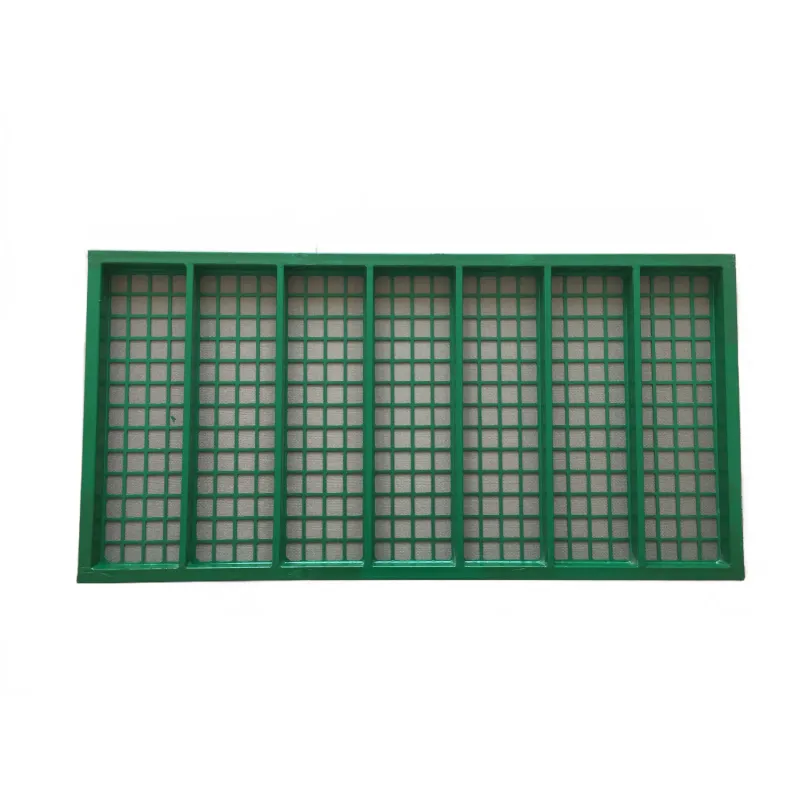

In summary, steel grid walkways represent a superior solution for various applications, combining durability, safety, customization, and environmental sustainability. Their robust construction and practicality make them ideal for industrial, commercial, and outdoor settings. As businesses increasingly prioritize employee safety and environmental responsibility, the adoption of steel grid walkways is likely to continue growing. Whether for pedestrian traffic in factories, access pathways over uneven terrain, or safety grids in commercial venues, steel grid walkways provide an effective and reliable option for meeting diverse needs. As industries evolve and new materials emerge, the timeless advantages of steel grid walkways will undoubtedly remain a vital component of modern infrastructure.