Conclusion

Conclusion

The organization of natural gas is also heavily influenced by regulatory frameworks at both national and international levels. Governments establish regulations to ensure the safety and environmental sustainability of natural gas operations. These regulations cover various aspects, including drilling practices, emissions standards, and pipeline safety. Compliance with these regulations is crucial for minimizing the environmental impact and enhancing public trust in the natural gas industry.

The importance of pressure regulation cannot be overstated. If the gas pressure is too high, it can damage appliances, leading to costly repairs and replacements. On the other hand, if the pressure is too low, appliances may not function correctly, potentially leading to inefficient energy use or even hazardous conditions.

In summary, pressure reduction devices are indispensable in ensuring safety, efficiency, and reliability across various industries. Their role in controlling pressure cannot be overstated, as they protect equipment, enhance operational efficiency, and minimize risks. As technology advances, we can expect to see even more sophisticated pressure reduction devices, incorporating smart technologies for enhanced monitoring and control. Understanding and utilizing these devices effectively is key to maintaining safe and efficient operations in any setting that relies on fluid pressure management.

The importance of pressure regulation cannot be overstated. Pressure reducing valves are integral to modern infrastructure, promoting safety, enhancing equipment efficiency, and ensuring reliable service across various applications. Understanding their function and significance can lead to better management and design of systems that depend on controlled pressure, ultimately benefiting both users and providers alike. By investing in quality PRVs, industries can protect their assets, improve performance, and contribute to safer operational environments.

In a typical setup, one gas is heated while the other is cooled. Heat exchangers can be classified into various types based on their design and flow arrangement, including counterflow, parallel flow, and crossflow configurations. In the counterflow design, the two gases flow in opposite directions, maximizing the temperature differential and enhancing heat transfer. Conversely, parallel flow heat exchangers see both gases moving in the same direction, which may lead to less effective heat exchange due to diminishing temperature differences.

Moreover, the power generation sector relies on safety valves to manage steam pressure in boilers and turbines. The failure of these systems could lead to severe accidents, including boiler explosions, which poses a risk not only to equipment but also to plant workers and nearby communities. Regular maintenance and testing of these valves are therefore vital to ensure they function correctly under varying operating conditions.

In political arenas, the influence of high-pressure advocacy organizations is evident in their ability to mobilize public opinion and drive policy changes. These organizations often employ strategies that leverage social media and grassroots campaigns to exert pressure on policymakers, demonstrating the power of collective action in high-pressure situations.

What is Gasification?

In order to maintain effective operation, gas pressure reducing stations are equipped with sophisticated measurement and monitoring systems. These systems track various parameters, such as inlet and outlet pressure, gas temperature, and flow rate. Information gathered from these sensors provides operators with real-time data, allowing for quick responses to any irregularities and enhancing overall safety.

Gas pressure vessels play a significant role in modern industrial operations, enabling the safe storage and management of gases used in a myriad of applications. Understanding the design principles, applications, and safety considerations associated with these vessels is crucial for ensuring their efficient and safe operation. As industries continue to evolve, advancements in technology and safety practices will further enhance the effectiveness of gas pressure vessels, contributing to safer and more efficient processes across the board.

- High Efficiency Gasification can achieve a higher energy conversion efficiency, often exceeding 80%, which maximizes energy recovery from waste materials.

Gas safety relief valves are indispensable in protecting systems that handle gas from potentially hazardous pressure situations. Understanding their function, ensuring regular maintenance, and adhering to safety standards are crucial in safeguarding both personnel and infrastructure. By prioritizing the effectiveness of these valves, industries can continue to operate safely and efficiently in their respective fields.

At its core, a decompression skid serves to manage the pressure of substances that may otherwise pose a risk if not adequately controlled. Typically composed of a series of valves, gauges, and other mechanical components, these skids facilitate the safe release of pressure while capturing and redirecting the material as needed. The design and configuration of each skid can vary depending on the specific application and requirements, including pressure ratings, flow rates, and the types of materials being handled.

Applications and Importance

What is a Pressure Regulator?

The Importance of Pressure Relief Valves

Regular maintenance and testing of pressure relief valves are essential for ensuring their reliability. Manufacturers recommend routine inspections, including checking the set pressure and verifying that the valve opens and closes as intended. Any signs of wear, corrosion, or leaks should be addressed immediately to prevent failures.

Moreover, the development of biogas and synthetic natural gas from renewable sources holds promise for the future. These alternatives not only enhance energy diversity but also reduce dependence on conventional fossil fuels. Some countries are already incorporating biogas into their energy mix, highlighting a path toward a sustainable future where natural gas can play an integral role in an environmentally responsible manner.

When high-pressure gas enters the valve, it pushes against the diaphragm and compresses the spring. As the diaphragm moves, it adjusts the valve opening, allowing only a set amount of gas to pass through to the downstream system. If the output pressure begins to rise above the desired level, the diaphragm moves against the force of the spring, closing the valve slightly to reduce flow. Conversely, if the outlet pressure drops, the diaphragm moves down, opening the valve and allowing more gas to flow through. This dynamic interaction ensures that the pressure remains stable, adapting to fluctuations in demand.

In conclusion, business organizations are essential components of the modern economy, driving growth, fostering competition, and contributing to the social fabric of communities. As the global economy continues to evolve, their importance will only increase. Entrepreneurs must remain agile, innovative, and socially conscious to thrive in this dynamic environment. As consumers, we also wield significant power by supporting businesses that align with our values. Ultimately, the interplay between businesses, consumers, and the government will shape a sustainable and prosperous future for all.

Moreover, gas regulators come in different types and designs, tailored to suit specific applications. For example, low-pressure regulators are typically used in residential settings, while high-pressure regulators serve industrial processes. Some regulators are designed for specific gas types, such as propane or natural gas, ensuring compatibility with the system they serve. Innovations in regulator technology, such as electronic pressure regulation, offer enhanced precision and adaptability for modern automated systems.

There are several types of relief valves, each tailored for specific applications. The most common types include

1. Shell and Tube Heat Exchangers This design features a series of tubes, one set carrying the hot gas and the other the cold gas. The heat is transferred through the tube walls. Shell and tube heat exchangers are known for their durability and are widely used in power plants and chemical processing.

- Manufacturing In industrial settings, gas pressure reducers regulate the pressure of gases needed for welding, cutting, and other manufacturing processes.

Importance of Gas Measurement

Types of Filter Separators

At their core, pressure reducing regulators operate on the principle of controlling the flow of fluids through a system. They accomplish this by utilizing a mechanism that adjusts the valve position based on the output pressure readings. Typically, a diaphragm is employed, which responds to the changes in output pressure. When the output pressure drops below a set threshold, the diaphragm moves to open the valve, allowing more fluid to flow through and thus increasing the pressure. Conversely, if the output pressure rises above the desired level, the diaphragm closes the valve to reduce flow and bring the pressure back within acceptable limits.

The organization of natural gas encompasses several aspects, including exploration, production, transportation, distribution, and regulation. Each of these components requires a structured approach to ensure efficiency, safety, and environmental compliance. Governments, international organizations, and private enterprises collaborate to create a framework that governs the entire natural gas supply chain.

At its core, regulation is aimed at preventing malpractice and safeguarding public welfare. In the financial sector, for example, regulators like the Securities and Exchange Commission (SEC) in the United States are tasked with overseeing the securities industry to protect investors. They enforce laws that ensure transparency and fairness in the market, thus helping to prevent fraudulent practices. This protection fosters trust in financial markets, encouraging both individual and institutional investment, which is vital for economic growth.

Pressure reduction devices function through various mechanisms, the most common being the spring-loaded diaphragm design. In this configuration, a diaphragm responds to incoming high pressure and modulates it to a predetermined lower pressure. The adjustment is typically done through a mechanical screw or digital settings in advanced models, allowing operators to fine-tune the output pressure as needed.

There are several types of gas valves, each designed for specific applications. One of the most common types is the shut-off valve, which allows for the complete interruption of gas flow. This type is particularly vital for emergency situations where gas leaks are suspected, enabling quick disconnection to prevent accidents.

However, while natural gas presents numerous benefits, it is not without challenges. One of the primary concerns is methane leakage during extraction and transportation. Methane is a potent greenhouse gas, with a global warming potential many times greater than CO2 over a shorter timeframe. Addressing leakage is crucial for ensuring that the shift to natural gas does not negate its environmental benefits. Advances in technology and stricter regulations can help minimize these emissions, ensuring that natural gas remains a cleaner alternative.

1. Replacement Shingles It's important to use shingles that match the existing roof in color and style. If the exact match isn’t available, consider using slightly different colors to create a patchwork effect that can blend with weathered areas.

The use of roof tiles dates back to ancient civilizations, but the Romans perfected the design and production of roof tiles, making them a staple of their architectural repertoire. During the Roman Republic and the subsequent Empire, the demand for durable and efficient building materials soared, especially as cities expanded and urbanization increased. Roof tiles made from fired clay provided an effective solution to waterproofing roofs, protecting homes and public buildings alike.

Clay tiles boast a rich history that dates back thousands of years. Used in ancient civilizations for both structural and decorative purposes, these tiles have evolved significantly over time. The term nib typically refers to the unique edge profile of the tile, which allows for easy interlocking and installation. Historically, nib tiles were crafted by skilled artisans who employed traditional methods, leading to beautiful variations in color, texture, and pattern. This artisanal quality is what makes clay nib tiles particularly appealing today, as there is a growing appreciation for handcrafted items in an increasingly industrialized world.

Despite their advantages, potential buyers should be aware of a few considerations. It's crucial to research and select high-quality synthetic shingles, as the market does contain lower-quality options that may not live up to their expectations. Consulting with a professional roofing contractor can provide insights into the best brands and products suited for specific needs.

2. Aesthetic Appeal Architectural shingles offer a more sophisticated and modern look compared to standard shingles. They come in a wide range of colors and styles, allowing homeowners to choose an option that complements their home's design. Their textured appearance mimics the look of more expensive roofing materials like wood shakes or slate, making them an attractive choice without the hefty price tag.

Conclusion

3. Wood Shingles and Shakes

Clay tiles date back to ancient times, with some of the earliest known examples originating from places like Mesopotamia and ancient Egypt. These civilizations employed clay tiles in their structures not only for their superior aesthetic appeal but also for their practicality. The natural clay was readily available and could easily be molded and fired to create durable tiles that withstand the test of time. Over the years, different cultures have developed unique styles and techniques, leading to a rich diversity in design, color, and finish.

Benefits of a Felt Roof for Your Conservatory

1. Replacement Shingles It's important to use shingles that match the existing roof in color and style. If the exact match isn’t available, consider using slightly different colors to create a patchwork effect that can blend with weathered areas.

Proper installation is key to ensuring the longevity of commercial roof shingles. Engaging a skilled roofing contractor who is experienced in commercial applications is critical. They will follow industry standards to ensure that shingles are laid correctly, with proper ventilation and waterproofing measures in place.

As architectural shingles approach the end of their life expectancy, certain signs can indicate that it’s time for a replacement. Homeowners should be vigilant for cracked, curled, or missing shingles. Granule loss, visible wear on the surface, and dark streaks could also signify that the shingles are nearing expiration. If you notice any of these signals, it might be time to consult a roofing professional to assess the condition of your roof.

Installing Steel Roofing Over Asphalt Shingles

As of late 2023, the average cost per square of asphalt shingles ranges from $90 to $100, excluding labor and additional material costs. This price can vary by factors such as the type of asphalt shingles chosen, the complexity of the roof, regional pricing differences, and the specific installation needs.

3. Installation Proper installation is critical to maximizing the lifespan of a steel roof. A roof that is poorly installed can lead to leaks, water damage, and premature wear. It’s advisable to hire experienced contractors who are well-versed in steel roofing installation.

Metal roofing has gained popularity for its longevity and durability. Metal shingles can last anywhere from 40 to 70 years, making them an excellent investment for homeowners looking for a long-term solution. They are resistant to various weather conditions, including hail and heavy snow, and they can also reflect heat, which can lead to energy savings during the hotter months. Although the initial cost may be higher compared to asphalt shingles, the extended lifespan and low maintenance needs make metal roofing a wise choice financially.

Average Cost of Asphalt Shingle Installation

In today’s eco-conscious world, sustainability is a crucial factor for many homeowners. Metal roofs are often made from recycled materials and are 100% recyclable at the end of their lifespan. In contrast, asphalt shingles contribute significantly to landfill waste, as they are not recyclable. By choosing a metal roof that mimics asphalt shingles, homeowners can support sustainable building practices while enjoying the benefits of a long-lasting material.

Preventive Measures

Once you have a clear understanding of these factors, it is advisable to create a budget based on estimated square footage and associated costs. On average, homeowners can expect to pay between $350 to $1,000 per square for a complete shingle roof installation, depending on the factors mentioned above.

Considerations

- Quality of Material Not all asphalt shingles are created equal. Higher-quality shingles are manufactured to resist wear and tear better than lower-quality options. Investing in better-quality shingles can result in a longer lifespan.

The use of stone coated metal roof tile helps promote the sustainable development of the construction industry. By using this environmentally friendly material, we can reduce the negative impact on the environment, promote the rational use and recycling of resources, and conform to the concept of sustainable development.

Final Checks and Cleanup

Aluminum Tile Metal Roofing A Durable and Stylish Choice

3. Optimal Cleaning Solution Consider using a cleaning solution specifically designed for roofs. Some solutions can help break down algae and moss more effectively than water alone, allowing for cleaner results without high pressure.

3. Easy Installation SBS rubber shingles are relatively lightweight compared to other roofing materials, which simplifies the installation process. Many manufacturers offer self-adhesive options that further reduce labor costs and installation time. Their ease of application makes them a favorite among contractors and DIY enthusiasts.

Installing asphalt roll roofing can be a fulfilling and cost-effective project for homeowners looking to improve their property's exterior. While the process is straightforward, always prioritize safety and ensure that you have the right materials to achieve the best results. With a well-executed installation, your asphalt roofing should provide reliable protection and enhance the aesthetic appeal of your home for many years to come.

1. Inspect and Prepare the Roof Ensure your roof deck is clean and in good condition. Remove any old roofing materials, debris, and screws. If the surface is uneven or damaged, repair it before proceeding.

Energy Efficiency

1. Aesthetic Appeal

2. Licensing and Insurance Always ensure that the roofing company you choose is fully licensed and insured. A licensed contractor will have the necessary training and knowledge to complete the job correctly, while insurance protects you from potential liabilities in case of accidents during the roofing process.

When embarking on a roofing project, whether it’s a new roof installation or a simple repair, understanding the cost of materials is crucial. One of the primary components you will encounter is roofing shingles, and knowing how much a bundle of roofing shingles costs can help you budget your project effectively.

In terms of maintenance, clay tiles are relatively easy to care for. Regular sweeping and occasional mopping are generally sufficient to keep them looking new. Unlike some materials that may require frequent sealing or special cleaning products, clay tiles are durable and stain-resistant, making them a practical choice for busy households.

1. Material Quality Higher-quality asphalt shingles, such as architectural shingles, can raise the cost significantly. While they may cost around $4 to $6 per square foot, they often come with longer warranties and enhanced aesthetics.

1. Type of Asphalt Shingles There are three main types of asphalt shingles three-tab, architectural, and luxury shingles. Three-tab shingles are the most basic and least expensive, typically costing between $80 and $120 per square. Architectural shingles, which provide a more dimensional appearance, tend to range from $100 to $180 per square. Luxury shingles, known for their high-quality and aesthetic appeal, can cost anywhere from $150 to $300 per square.

The cost of installing an architectural shingle roof can vary widely based on several factors. Here are some of the key aspects that influence pricing

Three-tab shingles are the most traditional and widely used form of asphalt roofing. Distinguished by their flat, rectangular shape, these shingles are designed to mimic the appearance of slate or tile roofs without the high cost. Three-tab shingles are typically lightweight and easy to install, making them a popular choice among budget-conscious homeowners.

1. Cost-Effective One of the most significant advantages of tri-tab shingles is their affordability. Compared to more complex roofing materials, such as metal or slate, tri-tab shingles provide a budget-friendly option without compromising quality.

- Conduct routine inspections, especially after severe weather.

Enhancing Durability

Aesthetic Versatility

Conclusion

The Appeal of Steel Roof Tiles A Durable and Stylish Choice for Your Home

1. Material Costs The price of architectural shingles themselves typically ranges from $90 to $100 per square (one square equals 100 square feet). Higher-end options with enhanced durability or unique designs can cost even more. It's essential to factor in this material cost when budgeting your roofing project.

Factors Influencing Prices

Tar is a thick, black, viscous liquid derived from the destructive distillation of organic materials, primarily coal and petroleum. In the context of asphalt shingles, tar is used primarily as a binding agent that holds the various layers of the shingles together. Asphalt shingles typically consist of a fiberglass or organic felt base saturated with asphalt, which is a refined form of tar. This combination provides an excellent barrier against moisture and sunlight, two major enemies of roof longevity.

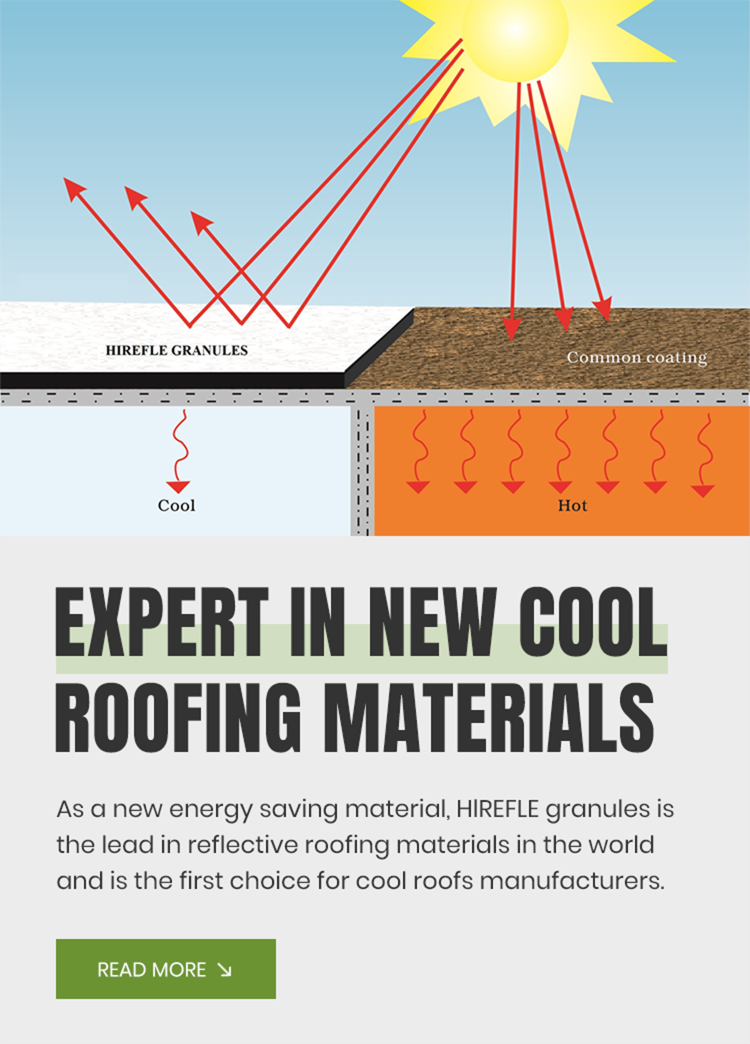

One of the most immediate advantages of sun reflecting roof sheets is their ability to enhance energy efficiency. Traditional dark-colored roofs can absorb up to 90% of solar radiation, significantly increasing indoor temperatures. This necessitates the use of air conditioning systems, which can lead to spikes in energy consumption and costs. In contrast, reflective roofing materials can reduce roof surface temperatures by up to 30 degrees Fahrenheit compared to conventional materials. This means that air conditioning units do not have to work as hard, leading to reduced energy bills and prolonged lifespan of cooling systems.