Understanding Coalescing Filters A Key to Efficient Fluid Management

Understanding Coalescing Filters A Key to Efficient Fluid Management

The primary function of a gas pressure reducing valve is to decrease and stabilize the pressure of a gas entering a system. When gas flows from a high-pressure source, such as a gas main, to a lower-pressure distribution system, the PRV adjusts the pressure to a predetermined level suitable for the downstream equipment. The valve operates on the principle of a diaphragm mechanism, where changes in downstream pressure result in adjustments to the valve opening, maintaining the desired output pressure.

Natural gas safety valves are devices designed to control the pressure within gas systems to prevent unsafe conditions. These valves automatically release excess pressure to protect pipelines, equipment, and facilities from damage that could result from over-pressurization. By ensuring that systems operate within designated pressure limits, safety valves contribute significantly to the safe handling of natural gas.

At its core, the smart regulator embodies the integration of technology into regulatory frameworks. Traditionally, regulators have relied on prescriptive rules and compliance checks to manage industries and protect consumers. However, these methods often struggle to keep pace with the rapid changes brought about by innovation. The smart regulator adopts a more agile and data-driven approach, utilizing tools like artificial intelligence, machine learning, and big data analytics to monitor trends, assess risks, and make informed decisions in real-time.

In summary, regulating valves are a vital component in the control and management of fluid systems across various industries. Their ability to adapt to changing conditions not only optimizes operational efficiency but also enhances safety and equipment longevity. Understanding the different types of regulating valves and their respective applications can help industries select the right valve for their specific needs, ultimately leading to improved performance and reliability in their operations.

Moreover, as the world increasingly embraces decarbonization, organizations in the natural gas sector must invest in infrastructure that supports hydrogen production and distribution, where natural gas can play a fundamental role. This shift will require careful planning, investment, and regulatory support to ensure a successful transition.

Maintenance and Best Practices

Moreover, the power generation sector relies on safety valves to manage steam pressure in boilers and turbines. The failure of these systems could lead to severe accidents, including boiler explosions, which poses a risk not only to equipment but also to plant workers and nearby communities. Regular maintenance and testing of these valves are therefore vital to ensure they function correctly under varying operating conditions.

The primary benefit of using pressure regulators is safety. By preventing overpressure situations, these devices significantly reduce the risk of accidents, including explosions or equipment failures. They also contribute to the efficiency of systems by ensuring optimal operating conditions, which can lead to lower energy consumption and reduced operating costs.

Applications of Pressure Relief Valves

In many developing countries, LPG has become a vital alternative to traditional biomass fuels, such as wood and coal. Cooking with biomass can release significant indoor air pollutants, leading to severe health issues for households that rely on these sources. LPG, being a cleaner option, has helped to mitigate these health risks. Many governments have launched initiatives to promote LPG adoption as part of their energy transition strategies, recognizing that this shift can enhance public health broadly while reducing environmental degradation.

Education and training also play vital roles in promoting gas safety. Workers who handle gas systems must be knowledgeable about the function and importance of safety valves. They should understand how to operate the valves, recognize signs of malfunction, and respond appropriately in emergencies. This knowledge can be the difference between averting a disaster and facing a severe incident.

How Cyclone Separators Work

At its core, regulation is aimed at preventing malpractice and safeguarding public welfare. In the financial sector, for example, regulators like the Securities and Exchange Commission (SEC) in the United States are tasked with overseeing the securities industry to protect investors. They enforce laws that ensure transparency and fairness in the market, thus helping to prevent fraudulent practices. This protection fosters trust in financial markets, encouraging both individual and institutional investment, which is vital for economic growth.

Applications in Various Industries

The mechanism behind coalescing filters is relatively straightforward. As a mixture flows through the filter medium, smaller droplets adhere to the fibers and merge with other droplets. This aggregation process continues until the droplets grow large enough to be separated by gravity or other means. This system is particularly effective in applications where the management of liquid contaminants in gas streams is paramount.

One of the primary responsibilities of commercial regulators is to establish and enforce laws designed to protect consumers from fraudulent practices. This includes regulating advertising standards, ensuring product safety, and overseeing financial transactions. By scrutinizing companies for compliance with these laws, regulators aim to build trust in the marketplace, ensuring that consumers have access to accurate information and safe products. For instance, organizations like the Federal Trade Commission (FTC) in the United States play a crucial role in preventing deceptive advertising that could lead consumers to make uninformed decisions.

Applications of Gas Pressure Regulating Valves

In conclusion, gas filtration is a critical process for managing industrial emissions and protecting public health and the environment. Through various methods such as mechanical filtration, adsorption, and chemical scrubbing, industries can effectively remove harmful pollutants from gas streams. As technology advances, the efficiency and effectiveness of gas filtration systems will continue to improve, promoting cleaner air and a more sustainable future. The ongoing challenge for industries will be to balance operational efficiency with environmental responsibility, ensuring that growth does not come at the expense of the planet.

Natural Gas Filtration Ensuring Clean and Safe Energy

One of the more advanced techniques involves the application of membrane technology, where selective barrier membranes allow only specific gas molecules to pass through while blocking others. This method is particularly useful for separating carbon dioxide and hydrogen sulfide, which are not only undesirable but can also result in environmental penalties if released into the atmosphere.

One of the most significant roles of regulators is to enhance public trust. In an era where misinformation can spread rapidly, having authoritative bodies that can validate information and enforce compliance becomes crucial. This trust is vital not only for the effective functioning of the economy but also for fostering innovation. When companies know that there are fair regulations in place, they are more likely to invest in new technologies and ideas, confident that their innovations will not be stifled by unfair practices or harmful competition.

The primary function of commercial regulators is to create and enforce rules that businesses must follow. This includes ensuring that companies adhere to standards of transparency and accountability. For example, in many countries, regulators require firms to disclose financial information, allowing investors and consumers to make informed decisions. Such transparency is vital for maintaining trust in the marketplace, as undisclosed information can lead to manipulative practices that ultimately harm consumers and the economy at large.

Importance of Gas Heat Exchangers

1. Spring-Loaded Valves These are the most widely used safety valves. They utilize a spring mechanism to hold the valve closed until the set pressure is reached. Once the pressure limit is exceeded, the spring mechanism compresses, allowing the valve to open.

Furthermore, gas pressure vessels are designed to handle a wide range of temperatures, as gases can expand or contract significantly with changes in temperature. This is why gas pressure vessels are often equipped with insulation or cooling systems to maintain a stable temperature inside the vessel. By regulating the temperature, operators can ensure that gases remain in their desired state and do not pose a risk of over-pressurization or other safety hazards.

There are several types of gas safety valves, each tailored to specific applications and safety requirements

. One common type is the pressure relief valve, which is designed to release excess gas pressure within the system to prevent over-pressurization. This type of valve is often used in conjunction with pressure regulators, ensuring that gas pressures remain within safe limits.Understanding Gas Metering An Essential Component of Energy Management

Natural gas filters are designed to remove impurities and contaminants from the gas stream. These impurities can include water, dust, sand, and other particulate matter that can accumulate during natural gas extraction, processing, and transportation. The presence of these contaminants can lead to several issues, including corrosion of pipelines, reduced efficiency of gas-burning appliances, and potential safety hazards such as explosions or leaks.

Understanding Natural Gas Pressure Regulators

- Precision Control Electric valves provide accurate and consistent flow regulation, which is critical in applications requiring strict adherence to flow rates.

Applications and Benefits

- Oil and Gas To control pressure levels in pipelines and storage tanks, preventing explosions or leaks.

The equipment employed in the natural gas industry plays a critical role in ensuring the smooth operation of the supply chain from extraction to end-user. As the world continues to seek cleaner energy sources, the importance of advancements in natural gas technology and equipment cannot be overstated. Continued investment in better equipment will enhance efficiency, reduce environmental impact, and ultimately support the transition to a more sustainable energy future.

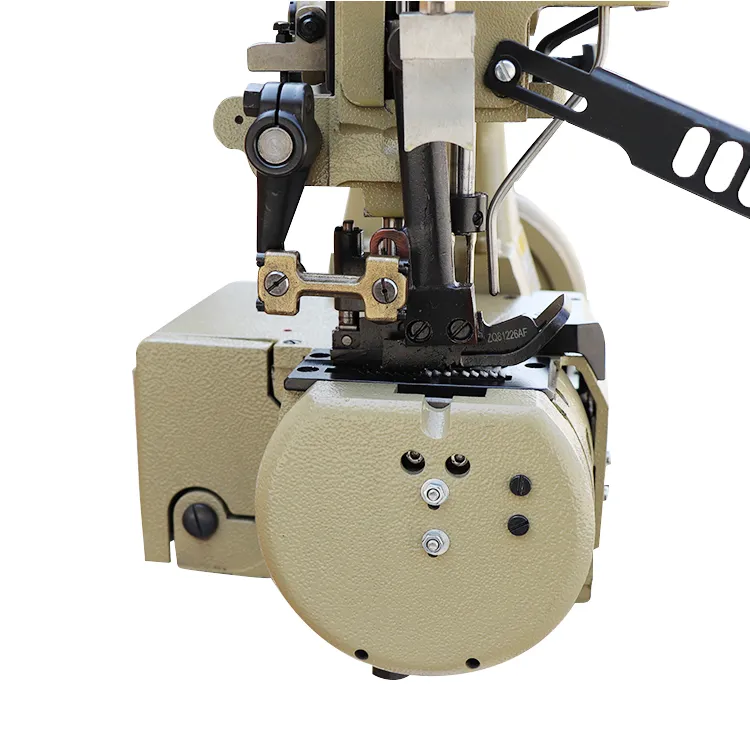

Double Needle Chain Stitch Sewing Machine An Overview

Additionally, the double needle setup allows for decorative stitching. The appearance of two parallel lines of stitching adds a professional touch to finished garments, making them visually appealing. This not only enhances the overall design but also allows for creative expression in garment construction.

Zig Zag Industrial Sewing Machine for Sale A Comprehensive Guide

Conclusion

Structure and Functionality

1. Local Fabric and Craft Stores Many brick-and-mortar craft stores stock self-threading sewing machines. Visiting a local store allows you to see the machines in action and ask questions to knowledgeable staff who can help guide your decision.

When considering the implementation of automatic bag closer machines, businesses must evaluate their specific requirements, including the type of products, production volume, and budget. Investing in the right technology can yield significant returns, from increased productivity and reduced labor costs to improved product quality and sustainability.

Automatic template sewing machines are designed to automate various sewing tasks, reducing the need for manual intervention. Unlike traditional sewing machines that require constant adjustments and oversight, these advanced machines use pre-programmed templates to execute intricate patterns and designs with precision. This automation allows for consistent quality across multiple pieces, which is particularly beneficial for mass production environments.

3. Janome Horizon Memory Craft 9450QCP This high-end model is designed for serious quilters and sewists. It features an extensive 350 built-in stitches, precise stitching controls, and an impressive working space, enabling you to handle large projects with ease.

3. Wide Throat Space When working with large pieces of leather, having enough throat space to maneuver the fabric is vital. A wider opening allows you to handle bulky items better, making it easier to sew bags, belts, or upholstery.

The significance of sewing machine chains extends beyond mere efficiency. They have contributed to the cultural and social shifts within the textile industry. With the ability to mass-produce garments, sewing machine chains have facilitated the rise of the fast fashion industry. This phenomenon has made fashionable clothing accessible to broader audiences, but it has also raised questions about sustainability and ethical labor practices. The ease of production has led to increased demand for cheap, quickly made garments, often at the expense of quality and the well-being of workers in developing countries.

4. Versatility Many overlocking machines are equipped to handle various types of materials and thicknesses. This versatility allows manufacturers to work with a range of carpet styles, from plush to Berber, significantly broadening their production capabilities.

Sofa upholstery sewing machines are designed to handle heavy fabrics and intricate stitching patterns that are typical in furniture manufacturing. Unlike standard sewing machines, these machines are built with robust motors and components that can withstand the demands of sewing thick layers of upholstery materials, such as leather, velvet, and heavy-duty canvas. This capability is essential, as sofas often require a combination of different fabrics and padding, necessitating a sewing machine that can perform at a high level without compromising on quality.

3. Stitching Machines For bags made of fabric or paper, stitching machines are often employed. These machines sew the edges together using thread, providing a robust and flexible seal. This method is especially suited for heavy or bulk materials where additional strength is necessary.

Sewing Challenges and Tips

Features of Heavy Duty Sewing Needles

In summary, an overlocker is an invaluable tool in both professional and home sewing environments. Its ability to create durable, clean finishes while simultaneously trimming fabric edges is unmatched by traditional sewing machines. Whether you are a seasoned tailor or a hobbyist, investing in an overlocker can significantly enhance your sewing experience, boost the quality of your garments, and open up new possibilities for creative expression. In the world of fabric construction, the overlocker is not just a convenient appliance; it is a game-changer.

Moreover, with the rise of sustainable practices in manufacturing, there is a growing trend towards eco-friendly sewing solutions. Newer models of compound feed machines are being designed with energy efficiency in mind, helping manufacturers lower their carbon footprint while maintaining high productivity levels.

At its core, the single needle lockstitch machine operates using a straightforward mechanism. It consists of two threads—a top thread and a bottom thread, typically wound on a bobbin. The top thread is looped through a needle, while the bottom thread is fed from the bobbin, which resides underneath the sewing plate. When the needle pierces the fabric, it creates a loop that intertwines with the bottom thread. This action produces a tight, secure stitch, which is the hallmark of lockstitch technology.

Another factor to consider in pricing is the timing of your purchase. Sewing machines are often discounted during promotional events such as Black Friday, Cyber Monday, or spring sales. Retailers may also offer discounts on previous year’s models to make way for newer inventory. Shoppers looking for a bargain can significantly benefit from keeping an eye on seasonal sales and clearance events, allowing them to purchase a higher-quality machine for a lower price.

Benefits for Manufacturers

In the world of sewing, the heavy-duty mechanical sewing machine stands out as a powerhouse tool, designed to handle a variety of fabrics and projects that demand greater strength and durability. Unlike standard sewing machines, which may struggle with thicker materials, heavy-duty machines are equipped to tackle everything from denim and canvas to thick upholstery fabrics, making them essential for both amateur and professional seamstresses alike.

Some thinner materials will require a special kind of stitch and also a lower ironing temperature. Thicker materials might also need to be sewn in layers. This process requires a powerful heavy duty sewing machine that can easily reach through the material without breaking or bending the needle.

This built-in walking foot will evenly feed your material as it grabs (with its traction like grip) the top of your material. This built in walking foot works in conjunction with the feed dogs which pull the bottom piece of the material through the sewing process.

Finishing Up

Keep in mind that just because a machine isn’t specifically labeled “heavy-duty,” doesn’t mean it can’t handle heavier fabrics, like denim, leather, or multiple layers. So when you are shopping for a sewing machine for jeans and denim it is important to know what kind of features to look for because heavy-duty sewing machines are made differently than basic home or beginner sewing machines.

1. Needles Use heavy-duty needles specifically designed for leather. These needles have a wedge-shaped point that helps pierce through the dense material without causing damage.

Overlockers Precision and Finishing Touches

1. Brand Recognition Well-established brands like Brother, Singer, Bernina, and Janome often carry a premium due to their reputation for quality and reliability. Investing in a machine from a reputable brand can be beneficial in terms of durability and customer support.

5. Ease of Adjustment Many industrial sergers come equipped with advanced tension control and stitch length settings, allowing operators to quickly adjust their settings based on fabric type and desired stitch characteristics.