.

Support groups are another essential component of organizations focused on pressure reduction. Groups like the Anxiety and Depression Association of America (ADAA) create safe spaces for individuals to share their experiences and connect with others facing similar challenges. This sense of community can alleviate feelings of isolation and foster a supportive network where individuals can receive encouragement and understanding. Hearing from others who have successfully navigated their stressors can provide hope and motivation to seek improvements in one’s own life.

Relief valves are critical components in various engineering applications, designed to protect systems from excessive pressure that could lead to catastrophic failures. These valves operate by automatically releasing pressure when it exceeds a predetermined level, ensuring the safety and integrity of equipment.

Conclusion

Types of Pressure Reducers

Natural gas filter separators are critical components in the processing and treatment of natural gas in the oil and gas industry. As the demand for cleaner and more efficient energy sources continues to grow, the role of filter separators becomes increasingly significant in ensuring that the natural gas delivered to consumers is clean, reliable, and safe.

The advancement of technology has further revolutionized gas organization. Modern gas management systems often include digital monitoring tools that provide real-time data on gas levels, usage patterns, and safety metrics. This technological integration allows for predictive maintenance and timely interventions, thereby preventing potential issues before they escalate. Additionally, the use of automation in gas distribution can significantly reduce human error, a leading cause of accidents in gas handling.

The materials used in constructing gas pressure vessels must ensure durability, strength, and resistance to extreme temperatures and corrosive substances. Steel, for example, is commonly used due to its high tensile strength, while coatings or linings are often applied to protect against specific chemicals.

In conclusion, pressure reducing regulators play an indispensable role in a multitude of applications across various industries. By providing a reliable means of controlling pressure, these devices enhance safety, improve process efficiency, and ensure the proper functioning of equipment. As technology advances, the development of more sophisticated and reliable regulators continues to enhance their importance in modern industrial systems. The understanding and proper maintenance of these devices will ensure they perform effectively, continuing to protect lives and improve operational efficiency in the sectors they serve.

In conclusion, pneumatic control valves are indispensable components in fluid control systems across various industries. Their ability to manage the flow of gases quickly and reliably contributes to enhanced efficiency, safety, and productivity in industrial processes. As technology advances, the role of these valves will continue to evolve, integrating with automation systems to meet the growing demands of modern manufacturing and engineering. Therefore, understanding and utilizing pneumatic control valves effectively can lead to significant benefits for any organization reliant on pneumatic applications.

High-pressure organizations, often referred to as high-stakes or high-performance entities, operate within environments that demand exceptional performance, quick decision-making, and high levels of accountability. These organizations can be found in various sectors, including healthcare, finance, technology, and emergency services. Their existence is driven by the need for rapid responses to complex challenges, often under significant constraints.

Moreover, the transition towards renewable energy has led to a growing emphasis on the role of natural gas as a bridge fuel. It can serve as a cleaner alternative to coal and oil, facilitating the transition to a low-carbon energy future. However, the industry must address challenges related to methane emissions and the long-term sustainability of natural gas extraction.

The Role of Regulators in Modern Society

One of the foremost aspects of smart organization is prioritizing tasks. The Eisenhower Matrix, a popular tool for time management, divides tasks into four categories based on urgency and importance. This method helps individuals focus on what truly matters, ensuring that they allocate their time and energy effectively. By distinguishing between urgent and important tasks, one can avoid the trap of working on activities that may seem pressing but contribute little to long-term goals.

Key Components of Gas Regulators

3. Inlet and Outlet Ports These are the entry and exit points through which gas flows into and out of the regulator. The inlet is connected to the gas supply line, while the outlet delivers gas to the application or user.

The Importance of Gas Valves in Modern Applications

The operation of a gas coalescer filter hinges on the principle of coalescence, where smaller droplets merge to form larger droplets. The filter element is typically made from a porous medium that captures liquid particles suspended in the gas flow.

Despite its importance, the nomination process is not without challenges. Issues such as bias and lack of transparency can undermine the effectiveness of nominations in any sector. It is essential for organizations and institutions to implement fair and equitable nomination processes that promote inclusivity and diversity. By doing so, they can ensure that deserving individuals are recognized and that the nomination system functions effectively.

In an era characterized by rapid technological advancements and evolving societal needs, the concept of smart regulation has emerged as a crucial framework for governments and organizations. Smart regulation is not only about creating laws and guidelines; it emphasizes a dynamic approach that leverages technology and data to enhance regulatory effectiveness while minimizing economic burden and ensuring public safety.

The functionality of metering systems has evolved significantly, particularly with the advent of smart technologies. Traditional metering systems often relied on manual readings, which were time-consuming and prone to human error. In contrast, smart meters enable real-time data collection and transmission, allowing for more accurate billing and immediate feedback to consumers about their usage. This innovation empowers users to manage their consumption better, promoting energy and resource conservation. Additionally, real-time monitoring can help utilities manage load more effectively, reducing the likelihood of outages and enhancing system reliability.

Types of Shut-off Valves

2. Two-Stage Pressure Reducers Suitable for applications requiring more precise control over pressure, these reducers first lower the pressure in two stages for smooth output.

To ensure the effective operation of gas safety valves, regular maintenance is paramount. Dust, corrosion, and other contaminants can impair the functioning of these valves, leading to potential failures. Routine inspections can identify wear and tear before they result in serious hazards, essentially acting as a preventive measure against gas leaks.

The organization of natural gas encompasses several aspects, including exploration, production, transportation, distribution, and regulation. Each of these components requires a structured approach to ensure efficiency, safety, and environmental compliance. Governments, international organizations, and private enterprises collaborate to create a framework that governs the entire natural gas supply chain.

3. Air-to-Air Heat Exchangers Commonly used in HVAC systems, these devices facilitate heat transfer between two air streams. They are often employed in energy recovery ventilators to improve indoor air quality while minimizing thermal losses.

Gas metering is a crucial aspect of energy management in both residential and commercial settings. As the world increasingly shifts towards cleaner energy sources, understanding the mechanisms of gas measurement has never been more important. This article aims to shed light on the significance of gas metering, how it works, and its implications for consumers and the environment.

So, what exactly is Flutter? At its core, Flutter is an open-source UI software development kit (SDK) designed for creating applications that can run on multiple platforms. It leverages the Dart programming language, which is easy to learn and offers benefits such as feature-rich libraries and strong support for asynchronous programming. Flutter's architecture is based on the concept of widgets, which are the building blocks of both the user interface and the app's underlying functionality. This widget-centric approach enables developers to create highly interactive and visually captivating applications.

Furthermore, with the rise of smart manufacturing and Industry 4.0, air control valves are increasingly integrated into automated systems. This connectivity allows for real-time monitoring and analysis, enabling businesses to optimize their operations continuously. Predictive maintenance, powered by data analytics, can identify potential issues before they escalate, further reducing downtime and maintenance costs.

5. Ultrasonic Gas Flow Measurement This method measures the flow rate of gas using ultrasonic sound waves. It is often employed in natural gas distribution networks and industrial applications due to its non-invasive nature and high accuracy.

3. Equipment Protection Appliances designed to operate at lower pressures can be damaged or operate inefficiently if subjected to high pressure. PRVs protect sensitive equipment from excess pressure, extending their lifespan and reducing maintenance costs.

The Impact of Vehicle-Mounted Equipment on Modern Transportation

In addition to aesthetics and energy efficiency, durability is a hallmark of modern sheet metal roofing. High-quality metal panels are designed to withstand extreme weather conditions, including heavy rain, snow, and high winds. Additionally, many manufacturers offer warranties on their products, extending for decades, which attests to the confidence they have in the longevity of their roofing solutions. This reliability is particularly appealing to commercial builders, who seek low-maintenance and long-lasting materials.

Moreover, metal roofing is lightweight compared to traditional materials like asphalt or wood shingles. This means less strain on the barn’s structure and potentially lower construction costs. The ease of installation associated with metal roofing can also reduce labor costs, making it a practical option for both new constructions and renovations.

De plus, DCBA se distingue par son engagement en faveur de l’environnement. L’entreprise utilise des matériaux recyclables et adopte des procédés de fabrication durables, ce qui fait de chaque achat une contribution à la préservation de notre planète. En choisissant leurs feuilles de toit, vous optez pour une solution écologique, tout en bénéficiant d’un produit de qualité.

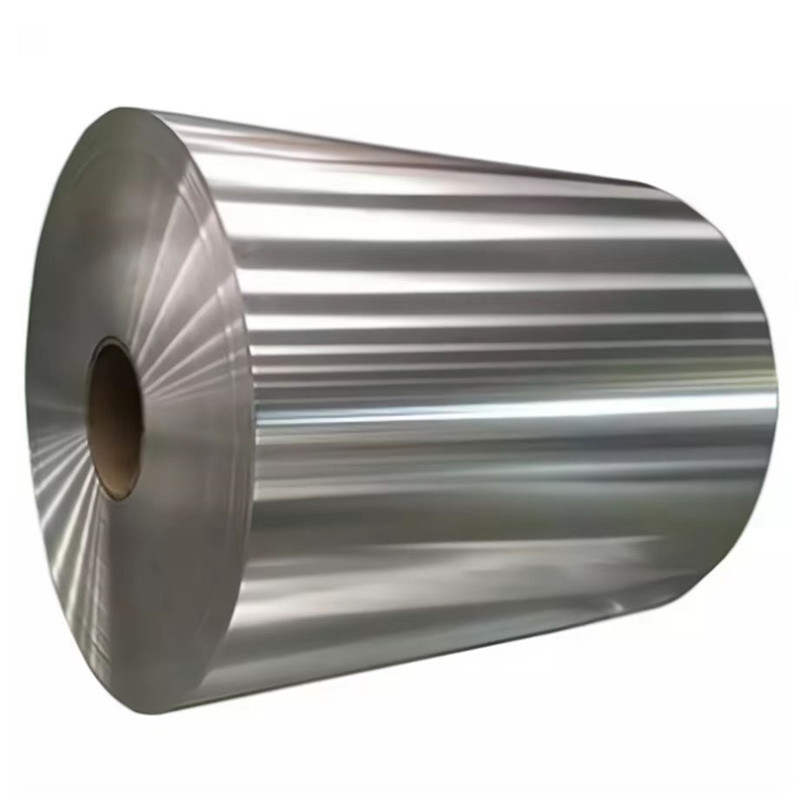

The Evolution and Advantages of Coil Metal Roofing A Comprehensive Overview

Star Wars tin box manufacturers play a vital role in celebrating the beloved franchise through durable and visually captivating memorabilia. These boxes not only store beloved collectibles but also serve as a testament to the creativity and passion of both the artists who design them and the fans who cherish them. As the Star Wars saga continues to evolve, so too will the imaginative designs and features of the tin boxes that capture the magic of a galaxy far, far away.

1. Research Local Suppliers Start by researching suppliers in your local area. Local suppliers often have a better understanding of regional building codes and environmental factors that might influence your selection of CGI sheets. Additionally, they can provide immediate support and quicker delivery times.

Longevity and Durability

Advantages of Tin Can Candles

A Variety of Designs

The world of manufacturing and materials has seen numerous innovations over the years, but few have had as substantial an impact on everyday life as tin plates, particularly those produced in China. Baret ware, a specific type of tin plate, has gained recognition for its unique properties and applications. This article delves into the evolution, significance, and modern uses of China baret ware tin plates.

2. Polyurethane Caulk This type provides strong adhesion and is excellent for gap-filling applications. Polyurethane caulk also has a durable finish, making it suitable for areas that are subject to abrasion.

1. Corrosion Resistance The primary advantage of galvanized angle iron is its resistance to rust and deterioration, which is particularly beneficial in regions with high humidity or harsh weather conditions.

5. Aesthetics Available in a variety of colors and finishes, 26 gauge sheet metal roofing can complement any architectural style. Whether one desires a modern look or a classic aesthetic, there is likely a metal roof that fits the vision.

Several factors influence the cost of sheet metal roofing, including

White metal roofing panels are typically made from galvanized steel or aluminum, coated with a layer of white paint or finish that reflects sunlight. This reflective quality is significant in reducing heat absorption, making buildings cooler and more energy-efficient. The use of white metal in roofing is not only practical but also enhances the overall visual appeal of a structure, providing a modern, clean look that complements various architectural styles.

The most common materials used for metal roofing include steel, aluminum, copper, and zinc. Each metal comes with its own set of properties and price points. For instance, galvanized steel is often more affordable compared to aluminum and copper, yet it provides excellent corrosion resistance. On the other hand, materials like copper, while more expensive, offer long-lasting benefits and unique aesthetics. The choice of material significantly impacts the overall cost of the metal sheets.

2. Innovative Designs The latch design can significantly impact its usability and aesthetic appeal. Manufacturers that invest in R&D to create innovative latch designs can offer clients tailored solutions that meet unique requirements.

Once the materials are prepared, they undergo a meticulous extrusion process where they are shaped into sheets of various thicknesses and sizes. Cutting-edge machinery allows for precise measurements, ensuring that the slip sheets are custom-fit for different roofing applications. After shaping, the sheets are subjected to rigorous quality control tests, checking for durability, flexibility, and the ability to withstand environmental stresses.

The Importance of Metal Tool Boxes

3. Experience and Reputation Suppliers with years of experience in the industry are often more trustworthy. You can research online reviews, request references, or check their portfolio to gauge their reputation.

Key Components of the Roof Inspection Sheet

The future of corrugated metal roofing appears bright, with ongoing innovations in design, materials, and manufacturing processes. As technology advances, factories will continue to refine their techniques, introducing smarter solutions that cater to evolving consumer needs. This includes the development of solar-reflective coatings, advanced insulation options, and customizable designs that appeal to a wide range of architectural styles.

Sustainability is another emerging consideration in the manufacturing sector. Many malleable iron galvanized manufacturers are now prioritizing environmentally friendly practices, such as using recycled materials and reducing waste during production. This focus on sustainability not only makes them more appealing to environmentally conscious consumers but also aligns with global efforts to reduce the carbon footprint of manufacturing processes.

In recent years, metal roofing has become an increasingly popular choice for homeowners looking to invest in durable, energy-efficient, and aesthetically appealing roofing solutions. Among the myriad of options available, Apex Metal Roofing stands out as a premier choice. If you're considering a new roof, here’s why buying from an Apex Metal Roofing factory might be one of the smartest decisions you make for your home.

In summary, MGO roof sheets represent a cutting-edge solution in modern roofing materials, providing a combination of durability, safety, and environmental benefits. As the demand for sustainable and resilient building materials continues to grow, MGO roof sheet suppliers and manufacturers are positioned at the forefront of this transformation. By prioritizing quality, innovation, and customer support, they play an essential role in shaping the future of construction and ensuring that builders and homeowners alike can rely on superior roofing solutions. Whether for new builds or renovations, MGO roof sheets are undoubtedly a wise investment for any project.

The manufacturing process itself is fascinating. Factories typically begin by designing the money boxes using computer-aided design (CAD) software, allowing them to visualize and refine their ideas efficiently. Once the design is finalized, metal sheets are cut and shaped using various techniques, including stamping or casting. The boxes then undergo painting and finishing processes that give them their distinctive appearances. Quality control is essential, ensuring that each product meets safety standards, especially for items aimed at children.

The versatility of fabric roof sheets is another reason for their rising popularity. They can be used in a wide range of applications, from sports arenas and exhibition halls to residential homes and agricultural facilities. Their ability to create open and airy spaces without the need for numerous support columns makes them particularly appealing for large venues. Additionally, the aesthetic potential of fabric roofs allows designers to create visually striking structures that can be customized in terms of color, texture, and translucency.

In addition to providing quality materials, many galvanized steel and iron suppliers also offer value-added services that can benefit businesses. These services may include custom cutting, welding, and coating options that allow companies to have materials tailored to their exact specifications. Such flexibility can enhance operational efficiencies by minimizing waste and reducing the time spent on procurement. As businesses increasingly turn to suppliers for comprehensive solutions, those that can offer a broader range of services will stand out in a competitive market.

Understanding Corrugated Roof Sheet Thickness and Its Importance

The market for Star Wars tin boxes is diverse, with various manufacturers offering everything from limited edition releases to more accessible, mass-produced items. Collectors often navigate this landscape by monitoring trends, participating in online forums, and attending conventions where exclusive items may be revealed. Prices can vary significantly, with rare editions fetching high premiums, while more common designs remain affordable for fans of all ages.

The manufacturing of corrugated roof sheets follows specific standards that define the acceptable thickness levels. These standards can vary based on the material used, such as steel, aluminum, or fiberglass. Typically, the thickness of corrugated metal roof sheets may range from 0.3 mm to 1.2 mm, with common choices being 0.375 mm, 0.5 mm, and 0.6 mm.

3. Minimum Order Quantities Some suppliers may have high minimum order requirements, which could be a barrier for small businesses or those just starting. It is essential to find suppliers that offer flexible ordering options.

In the rapidly evolving world of construction and architecture, roof panel sheet metal has emerged as a crucial component in the design and functionality of modern structures. As energy conservation and sustainability become more pressing concerns, the demand for high-quality materials such as sheet metal roofing is increasing. This has led to a significant rise in the importance of roof panel sheet metal manufacturers, who play a vital role in ensuring that building projects meet current aesthetic, functional, and environmental standards.

3. Sustainability Practices Inquire about the supplier’s sustainability practices. Do they use environmentally friendly materials? What measures do they take to reduce waste during production? Suppliers dedicated to eco-friendly practices can bolster your brand’s commitment to sustainability.

Dôležitosť výberu dodávateľov

The benefits of tin can candles extend beyond just the eco-friendly production process. These candles are highly customizable. Consumers can choose or create blends that resonate with their personal preferences, often opting for bespoke options available at local artisan markets or online stores. Since they are crafted from recyclable material, they can also be repurposed after the candle has burnt out, serving as planters, holders for office supplies, or even decorative pieces.

Moreover, comprehensive records of past inspections can be beneficial when negotiating property sales, as prospective buyers will appreciate the transparency regarding the roof's condition.

Benefits of Aluminium Foil Sheets in Roofing

Market Trends and Future Prospects

3. Weather Resistance RVs are often exposed to various weather conditions, from intense sun to torrential rain. Sheet metal, especially when coated with protective finishes, provides excellent weather resistance. This feature prevents issues such as rust and leaks, ensuring that the interior of the RV remains dry and safe.

4. Customer Service An efficient supplier should be responsive and willing to assist customers with inquiries related to product specifications and installation. A supplier’s dedication to customer service can significantly enhance the purchasing experience.

Modern tin plate ceiling factories leverage advanced technologies, such as computer-aided design (CAD), to create custom patterns and sizes

. This capability allows architects and homeowners to personalize their spaces while maintaining the traditional charm associated with tin ceilings.Another advantage of modern metal roofing is its energy efficiency. Many metal roofs are coated with reflective finishes that reduce heat absorption, keeping buildings cooler during hot months and subsequently lowering energy bills. This attribute is particularly appealing in regions with extreme climates where air conditioning costs can become burdensome. Furthermore, the longevity of metal roofs means fewer resources are consumed over time, making them a more sustainable building option.

Durability and Security

4. Eco-Friendly Option Metal roofing materials are often recyclable, making them an environmentally conscious choice. Many manufacturers are committed to sustainability, using recycled materials to produce metal sheets. This characteristic not only helps reduce waste but also supports green building initiatives.

Metalowe kuwety ogrodowe Wybr producenta

अल्बुकर्क, न्यू मैक्सिको, अपने जीवंत सांस्कृतिक धरोहर और विविध उद्योगों के लिए जाना जाता है। इनमें से एक महत्वपूर्ण उद्योग टिन कैन निर्माण है, जो न केवल स्थानीय अर्थव्यवस्था को बढ़ावा देता है, बल्कि खाद्य पैकेजिंग के क्षेत्र में भी एक महत्वपूर्ण भूमिका निभाता है। टिन कैन, जिन्हें स्टील और टिन के संयोजन से बनाया जाता है, लंबे समय तक खाद्य सामग्री को सुरक्षित रखने में सक्षम होते हैं।

Steel roof sheets come in numerous sizes, generally measured in length, width, and thickness. The most common widths for steel sheets range from 600 mm to 1200 mm, while lengths can vary anywhere from 1 meter to over 12 meters. Thicknesses usually range from 0.3 mm to 1.0 mm, depending on the application and structural requirements.

Итак, если вы ищете поставщика МГО кровельных листов, важно учесть все вышеперечисленные аспекты. Надежный производитель предложит вам не только качественные материалы, но и полное сопровождение вашего проекта, что позволит вам избежать множества проблем в процессе строительства. Делайте выбор ответственно, и ваша крыша станет надежной защитой вашего дома на долгие годы.