Understanding Gas Coalescer Filters Fundamentals and Applications

Understanding Gas Coalescer Filters Fundamentals and Applications

3. Globe Valves These valves are designed for throttling flow, featuring a linear motion mechanism that allows for precise control of fluid movement. While they may cause more pressure loss than gate valves, they are effective in applications requiring variable flow rates.

Another critical application is in laboratory settings, where gas pressure reducers help maintain precise gas flows for experiments and processes. This precision is vital for achieving reliable results, particularly in research and development where accuracy is paramount.

Gas regulators are essential devices used to control the pressure of gas in various industrial applications. They play a critical role in ensuring the safe and efficient operation of equipment that relies on gas as a fuel or raw material. With the increasing reliance on natural gas, propane, and other gaseous fuels in industries such as manufacturing, heating, and energy production, understanding the function and significance of gas regulators has never been more vital.

Conclusion

In summary, relief valves are indispensable devices that ensure the safe operation of various systems by controlling and limiting pressure. Their functionality not only protects equipment but also plays a vital role in safeguarding human lives and the environment. As industries continue to evolve and expand, the importance of reliable and efficient relief valves will only grow, emphasizing the need for innovation and adherence to safety standards in pressure management solutions. Understanding and implementing proper relief valve solutions can lead to enhanced safety, reliability, and efficiency in all operational processes.

The success of supercharger technology has sparked interest among other automotive manufacturers as well. Companies like Ford, Volkswagen, and General Motors are now investing in their own fast-charging infrastructure, recognizing that a robust charging network is essential for the widespread adoption of electric vehicles. Collaborations and partnerships between automakers and charging networks are becoming increasingly common, signaling that the industry understands the importance of making EVs accessible and convenient for all drivers.

As supercharger technology continues to evolve, there are still challenges to address. The rollout of supercharging infrastructure must keep pace with the growing number of electric vehicles on the road. Additionally, ensuring compatibility between different electric vehicle brands and charging systems is vital for creating an inclusive charging network that benefits all users.

- Water Treatment In water distribution systems, maintaining acceptable pressure levels is essential for both operational reliability and regulatory compliance. Pressure regulating skids ensure water is delivered at appropriate pressures, reducing the risk of pipe bursts and leaks.

Another significant aspect of high-pressure organizations is their focus on leadership. Leaders in these environments are often tasked with making quick yet informed decisions, requiring a balance between intuition and analytical thinking. Effective leaders foster a culture of trust and collaboration, empowering team members to take initiative and contribute actively to the organization's goals. They also recognize the importance of managing stress and provide support systems to help team members cope with the demands of their roles.

The safety and efficiency of a gas pressure reducing station heavily depend on regular maintenance routines and adherence to safety protocols. Inspections are routinely conducted to ensure all components are functioning correctly, with an emphasis on identifying wear and tear that could lead to failure. Operators must also be trained in emergency response procedures, ensuring that they can react swiftly in case of a mishap.

One of the primary benefits of utilizing pressure reducing devices is enhanced safety. By preventing overpressure situations, these devices protect both personnel and equipment. Additionally, they contribute to energy efficiency. Properly regulated pressure can lead to reduced energy consumption since equipment does not have to work harder to overcome excessive pressure.

Functionality and Operations

- Automation They can be easily automated and integrated into control systems, enhancing operational efficiency. This automation reduces the need for manual intervention, lowering the likelihood of human error.

Conclusion

One of the key advantages of basket strainers is their ability to effectively trap large particles such as debris, dirt, and scale without significantly impeding the flow of the fluid. This is achieved through a perforated or mesh-lined basket that captures the particles as the fluid passes through. The removable basket makes it easy to clean and maintain the strainer, extending its service life and reducing downtime.

1. Wye Type Strainers These strainers are designed in the shape of a Y and are commonly used in horizontal piping applications. They provide efficient filtration with a lower pressure loss.

In conclusion, pneumatic control valves are essential components in many industrial processes, providing efficient and precise control of air and gas flows. Their ability to react quickly to control signals, combined with their versatility and robust design, makes them invaluable in various applications. As industries continue to evolve and automate, the importance of reliable pneumatic control valves will undoubtedly grow, driving advancements in technology and improving productivity across sectors. Understanding how these valves work and their role in systems can help engineers and operators optimize their use, ensuring that processes run smoothly and efficiently.

Distribution Station A Crucial Hub in Supply Chain Logistics

The organization of natural gas begins with its extraction. It is typically found in underground rock formations and is often associated with other fossil fuels such as oil. The extraction process involves drilling wells, and the gas is collected through pipelines. Once extracted, natural gas is transported via a vast network of pipelines which can span thousands of miles, connecting production sites to markets. This transportation infrastructure is essential for the distribution of natural gas to residential, commercial, and industrial users.

The design and technology of gasification equipment have evolved significantly over the past few decades. Modern gasifiers come in various types, including fixed-bed, fluidized-bed, and entrained-flow gasifiers, each tailored for specific feedstocks and requirements. Fixed-bed gasifiers are often used for converting solid biomass and exhibit simplicity in operation, while fluidized-bed gasifiers provide better heat transfer and are suitable for a variety of feedstocks, including waste oils. Entrained-flow gasifiers, on the other hand, are designed for high-efficiency operation with pulverized feedstock, making them ideal for coal gasification.

The Concept of Smart Regulation A Forward-Looking Approach

The advantages of adopting a Smart Regulator approach are manifold. First and foremost, businesses benefit from reduced compliance costs. By automating routine compliance checks and utilizing real-time data, organizations can allocate resources more effectively and reduce the burden of manual compliance tasks. This, in turn, fosters innovation, as businesses can dedicate more time and energy to product development and market expansion rather than being ensnared in bureaucratic processes.

Gasification has emerged as a promising technology for converting organic or fossil-based materials into a clean syngas, which can subsequently be utilized for various applications like electricity generation, chemical production, and even fuel synthesis. The development of gasification equipment is pivotal in facilitating this process, allowing for improved efficiency, reduced emissions, and better resource management.

In terms of construction materials, shut-off valves can be made from a variety of substances, including brass, stainless steel, plastic, and cast iron, each differing in terms of durability, corrosion resistance, and temperature tolerance. For example, stainless steel valves are preferred in industries dealing with corrosive substances due to their high resistance to rust and chemical damage. Consequently, engineers must consider the application environment when selecting materials to ensure longevity and optimal performance.

1. Electric Gate Valves These valves are primarily used for on/off control. They are designed for full flow, with minimal pressure drop when open, making them suitable for various industrial applications.

The role of closing valves in fluid control systems is integral to the functionality, safety, and efficiency of various industries. By selecting the appropriate type of closing valve for specific applications, engineers and operators can ensure optimal performance and reliability in fluid management. As technologies advance, the design and materials used in closing valves continue to evolve, promising even greater efficiency and safety in fluid control systems. The closing valve may seem like a simple component, but its impact on industrial processes is profound and far-reaching.

What is a Pressure Reducing Device?

2. Gas Turbines In power generation, gas turbines convert natural gas into electricity, offering a more efficient and cleaner alternative compared to coal or oil.

5. Durability and Build Quality Heavy-duty machines are typically constructed from metal, making them more durable than plastic-framed counterparts. Investing in a sturdy machine ensures longevity, even under heavy use.

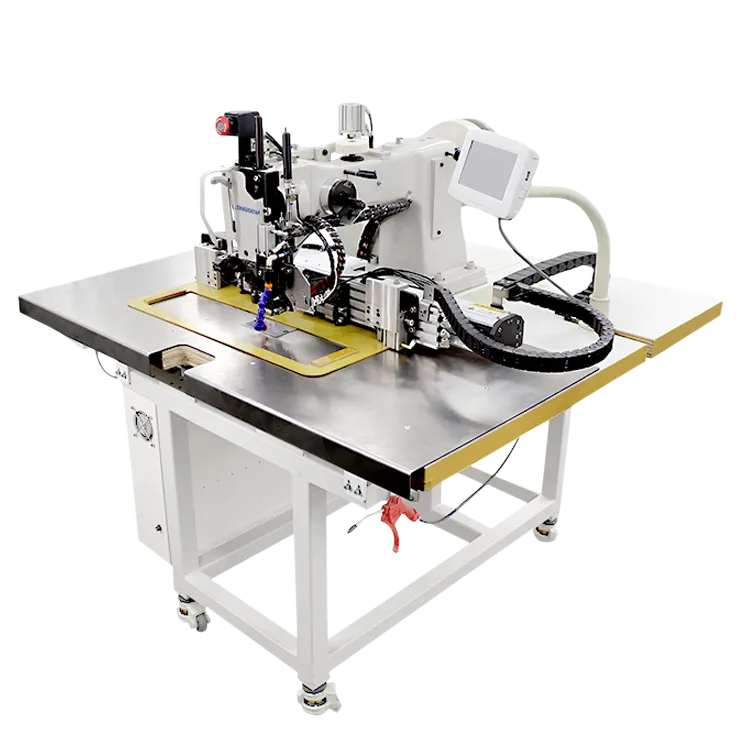

Bag making machines come in various types, each designed to produce different kinds of bags. Some popular types include flat bag making machines, drawstring bag machines, and shopping bag making machines. Each machine is engineered to cater to specific requirements in terms of size, material, and design. Over the years, technological advancements have made these machines faster and more accurate, thus reducing production time and increasing output.

5. Take Your Time Patience is key. Taking your time while sewing will enhance the quality of your work and ensure that each seam is neatly finished.

The technological advancements in hi-speed lockstitch machines also include features such as programmable sewing patterns, automatic thread cutting, and built-in sensors that detect thread breakage. These innovations not only expedite the sewing process but also minimize the risk of errors and material wastage. This level of precision is particularly beneficial in high-stake environments, such as fashion design, where the margin for error may be minimal.

User Friendliness and Accessibility

Exploring the Zig Zag Stitch Machine A Versatile Tool for Seamstresses

These machines are beginner-friendly, making them an excellent choice for those just starting their sewing journey. You don't need to be a sewing expert to operate them effectively.

Commercial upholstery is the making or fixing furniture used in business settings, like bar seats in diners, chairs in movie theaters, office furniture, or restaurant seats. Robust materials are often used because these things get used a lot and worn down. This means a heavy-duty sewing machine is needed because it can handle thick fabrics and make strong stitches. Without such a machine, you might have to deal with broken needles, stitches that aren’t even or aren’t strong enough, and upholstered business furniture that doesn’t last as long or looks professional.

1. Stitch Variety Professional upholstery sewing machines typically offer an array of stitches, including straight, zigzag, and specialty stitches. This variety enables upholsterers to create tailored designs and finishes, elevating the aesthetic appeal of their work.

Quality is a key concern for any textile manufacturer. Overlock sewing machines contribute to higher quality outputs by creating durable seams that withstand stress and movement. The overlocking stitch is inherently stronger and more flexible than a standard straight stitch, making it ideal for garments that require stretch, such as athletic wear or fitted clothing. This ensures that the end products do not only look good but also last longer, reducing return rates and improving customer satisfaction.

For fashion brands, the double tailor machine offers a substantial competitive advantage. With the ability to produce garments faster and more efficiently, brands can respond quickly to market trends and consumer demands. In an industry where timing is critical, being able to execute designs rapidly can make a significant difference in a brand's success. The machine’s efficiency also translates to lower production costs, allowing companies to allocate resources more effectively and potentially pass savings onto consumers.

Cylinder arm sewing machines are versatile tools utilized in various leatherworking applications. In fashion, they are essential for crafting bespoke handbags, jackets, and footwear, where unique shapes and designs are common. In the automotive industry, these machines are used to stitch leather upholstery, ensuring a luxurious finish in high-end vehicles. Furthermore, the agricultural sector benefits from cylinder arm machines for creating durable leather gear and saddles, reinforcing the machine’s significance across multiple industries.

As sewing technology continues to advance, programmable pattern sewing machines represent a significant leap forward, catering to the needs of a broad spectrum of users. They empower individuals to turn their creative visions into reality with speed and precision, making sewing more accessible and enjoyable than ever before. Whether you are a seasoned seamstress or a novice looking to explore the craft, investing in a programmable pattern sewing machine could truly elevate your sewing experience and open up a world of possibilities.

Another important feature to consider is the machine’s stitching capabilities. Look for a heavy duty sewing machine that offers a variety of stitch options, including straight stitch, zigzag stitch, and decorative stitches. This will give you the flexibility to tackle a wide range of sewing projects with ease.

Beyond speed and efficiency, high-speed overlock sewing machines play a crucial role in enhancing the quality and aesthetic appeal of finished garments. The clean edges produced by overlocking not only improve garment durability but also elevate the overall look by providing a polished finish. High-quality seams are vital for meeting customer expectations, particularly in the fashion industry where the slightest flaw can lead to significant dissatisfaction and returns.

In addition to its superior feeding mechanism, a compound feed heavy-duty sewing machine is also equipped with a powerful motor. This allows the machine to sew through multiple layers of fabric, thick materials, and heavy-duty materials with ease. The high-speed motor ensures fast and efficient sewing, making it ideal for large projects or production sewing.

In the world of upholstery, the quality and efficiency of sewing machines play a crucial role in shaping the final product. Professional upholstery sewing machines are designed specifically to meet the demanding needs of upholsterers, offering features that greatly enhance both performance and productivity. This article delves into the significance of these specialized machines and their impact on the upholstery industry.

Improving Craftsmanship

Understanding Thick Threads

A long arm sewing machine typically features an extended arm length, allowing users to work on larger projects with ease. This design is particularly beneficial for quilters who often handle large quilts that require a wider workspace. With a long arm machine, the entire quilt can be maneuvered smoothly without the need to constantly reposition the fabric, reducing the risk of puckering and misalignment.

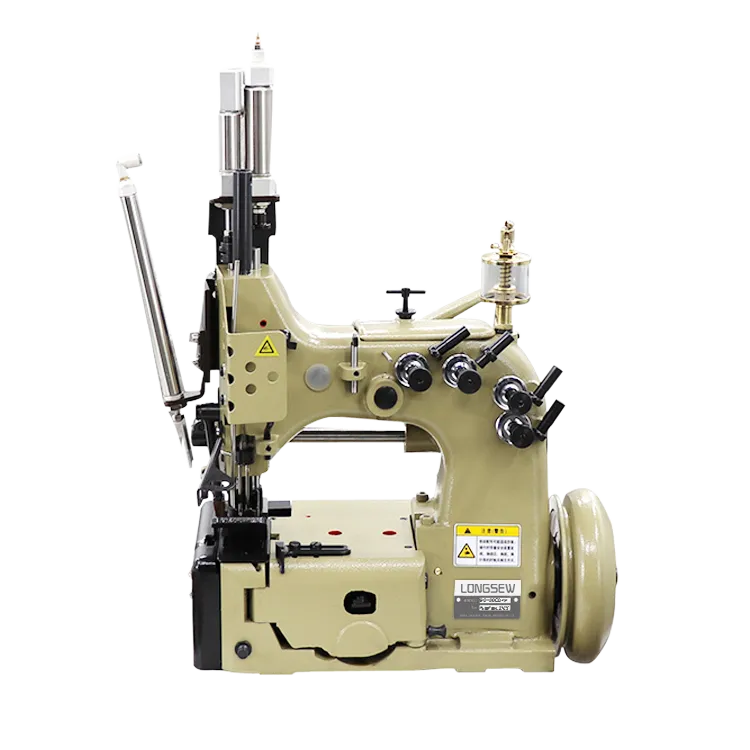

In today’s fast-paced industrial environment, efficient packaging is crucial for businesses aiming to maintain a competitive edge. Among the various elements of the packaging process, bag closing machinery plays a vital role in ensuring that products are securely sealed and ready for distribution. As industries continue to evolve, the demand for innovative bag closing solutions has surged, leading to the development of various types of machinery designed to cater to different needs.

The Cub Leather Sewing Machine A Tailored Solution for Leather Enthusiasts

There are a few ways to tell if a machine has reached its limit, such as if it breaks down often, has inconsistent stitch quality, or lacks advanced features. Such restrictions can make it harder to be creative and productive, which could mean it’s time to think about a change.

A pair of raw or selvage denim jeans is quite thick, requiring special attention during the sewing process. A heavy-duty sewing machine equipped with a strong motor and construction is essential for piercing through multiple layers of such dense material. This powerful machine is not just about brute force. It helps to maintain uniform stitch length and tension while sewing denim to prevent puckering and to ensure a clean, polished finish.

4. Material Usage Waste generated during the overlocking process must also be factored into the overall cost. Efficient use of materials can help in minimizing waste and lowering costs.

Conclusion

The primary advantages of utilizing industrial sewing machines for leatherwork include increased production speed, improved stitching accuracy, and the ability to handle thicker materials. The automation and precision of these machines reduce labor costs and minimize material waste, thereby increasing overall profitability for manufacturers.