The Future of Gas Distribution Stations

The Future of Gas Distribution Stations

Modern gas pressure reducing stations often integrate smart technologies, enabling remote monitoring and control. By leveraging the Internet of Things (IoT), operators can monitor multiple stations from a central location, improving response times to potential issues and optimizing operational efficiency.

The International Society of Hypertension is a worldwide organization dedicated to reducing the global burden of hypertension through advocacy, research, and education. Founded in 1966, the ISH brings together health professionals from various fields to focus on high blood pressure prevention and management. They provide resources for evidence-based treatment protocols and promote research to better understand the underlying causes of hypertension. Their emphasis on global collaboration in research facilitates the sharing of knowledge and strategies essential for managing hypertension in different populations.

Safety Considerations

However, as the LNG market grows, the challenges and environmental considerations associated with regasification equipment cannot be overlooked. The construction and operation of regasification facilities can have ecological impacts, such as water usage and emissions from auxiliary systems. Therefore, companies are increasingly investing in innovative technologies and practices to mitigate these environmental concerns, including the use of renewable energy sources in the vaporization process.

Importance of Filtration in Natural Gas Processing

2. Manual Shut-off Valves These valves require manual intervention to close off the gas supply. They are often installed in strategic locations for emergency shut-off.

Moreover, proper regulation can prolong the lifespan of appliances. When appliances operate consistently within safe thresholds, they experience less wear and tear, leading to fewer breakdowns and maintenance issues. This quality assurance translates to greater satisfaction for homeowners, as they don’t have to frequently replace or repair their devices.

A distribution station acts as a centralized point where goods are received, sorted, and dispatched to various destinations. This process typically begins with receiving shipments from manufacturers or suppliers. Upon arrival, the goods are unloaded and cataloged, allowing for effective inventory management. Advanced tracking systems and technologies, including RFID tags and barcoding, facilitate real-time monitoring of inventory levels. This not only improves accuracy but also enhances efficiency by reducing the time spent on manual inventory checks.

Moreover, pneumatic control valves are characterized by their durability and reliability

. They are typically designed to handle high pressures and can function effectively in extreme temperatures. This resilience makes them suitable for demanding environments, such as factories and warehouses, where they contribute to efficient workflow and increased productivity.In conclusion, superchargers are more than just a solution to charging electric vehicles; they are a key driver in the transition to a sustainable transportation framework. By reducing charging times, alleviating range anxiety, and expanding access to charging stations, they have positioned electric vehicles as a viable alternative to traditional gasoline cars. As technology continues to evolve, we can expect superchargers to play an increasingly vital role in shaping the future of mobility, reaffirming our commitment to a cleaner, greener planet.

The significance of relief valves cannot be overstated. Overpressure situations can lead to catastrophic failures, including explosions, equipment damage, and even injuries or fatalities. By preventing these scenarios, relief valves contribute to operational efficiency and safety.

Applications

3. Operational Efficiency By maintaining optimal pressure levels, these valves contribute to the overall efficiency of gas systems. They allow processes to run smoothly without interruptions caused by pressure anomalies.

2. Safety With built-in features like pressure relief and regulation, these valves help maintain safe operating conditions. This is critical in environments where malfunction could lead to catastrophic failures.

However, despite its advantages, there are some challenges associated with CNG. One of the primary obstacles is the availability and accessibility of refueling stations. In many regions, CNG infrastructure is still underdeveloped, leading to concerns about the feasibility of long-distance travel. Additionally, while the production of CNG is cleaner than other fossil fuels, it still involves extraction processes that can have environmental impacts, such as methane leakage during gas extraction and transportation. As such, it is essential to continue refining extraction methods and improving the sustainability of the entire supply chain.

How Gas Pressure Reducers Work

3. Efficiency By maintaining consistent pressure, gas pressure regulators help optimize the performance of appliances and machinery, improving efficiency and reducing operational costs.

In the context of natural gas transmission, PRS helps maintain the integrity of the pipeline infrastructure. High-pressure pipelines can be prone to leaks and failures, which can have serious environmental and safety implications. By controlling the pressure within the system, PRS not only extends the lifespan of pipelines but also mitigates the risk of gas leaks.

What is a Gas Pressure Reduction Station?

1. In Vehicles Electric auxiliary heaters are increasingly common in electric and hybrid vehicles. Unlike conventional internal combustion engines that produce waste heat during operation, electric drivetrains often lack sufficient residual heat during colder months. An auxiliary heater can instantly provide warmth to the cabin, enhancing passenger comfort while preventing battery drain.

One of the most significant advantages of natural gas is its efficiency and environmental friendliness. When burned, it produces fewer pollutants compared to coal and oil, resulting in lower carbon dioxide emissions. This characteristic positions natural gas as a transitional fuel in the shift toward renewable energy sources. As societies aim to reduce greenhouse gas emissions and combat climate change, natural gas serves as a vital component in the global energy supply chain.

3. Safety Systems Given that natural gas is flammable, safety measures such as gas detection systems, emergency shut-off valves, and robust monitoring protocols are vital to prevent leaks and accidents.

Electric water heaters are renowned for their convenience and efficiency. Here are some key benefits

Another important category is the gas-phase filter, which targets gaseous pollutants such as volatile organic compounds (VOCs), sulfur dioxide (SO₂), and nitrogen oxides (NOₓ). These substances pose significant health risks and contribute to the phenomena of smog and acid rain. Chemical sorbents, such as activated carbon, zeolites, and silica gels, are commonly used in gas-phase filters to adsorb or react with these harmful gases, thus preventing them from entering the atmosphere.

Regulatory Standards

Furthermore, many businesses are finding that going green can be economically advantageous. Consumers increasingly prefer to buy products from companies with environmentally friendly practices. Therefore, by utilizing gas filters and promoting cleaner production methods, industries can attract a more eco-conscious customer base.

The importance of gas pressure regulating valves cannot be overstated. They are essential for

In conclusion, gas boosters are integral to enhancing efficiency in gas distribution networks. Their ability to increase pressure, improve system reliability, and integrate with renewable sources makes them invaluable in the quest for a sustainable energy future. As technological advancements continue to evolve, the role of gas boosters will likely expand, supporting a more efficient and environmentally friendly energy landscape. The continuous development and implementation of these devices will be crucial as we strive towards a balanced energy ecosystem that meets the needs of today while safeguarding the health of our planet for future generations.

Most types of electrical tape have a maximum operating temperature between 80°C and 130°C.

2. Durability Made to withstand extreme temperatures and harsh environments, self-fusing rubber tape maintains its effectiveness and integrity over time. Its resistance to abrasion, UV radiation, and chemical exposure ensures longevity, even in challenging conditions.

Conclusion

Butyl Sealant tapeis crafted from butyl rubber, a man-made material that was first synthesized during the early 1900s in order to strengthen traditional rubber adhesives. This innovative product surpasses natural rubbers in its capacity to stay sticky at far colder temperatures - an impressive feature that sets it apart from other adhesive materials.

how to use self amalgamating rubber tape. Work your way along the length of the repair area, ensuring that the tape is evenly applied and makes good contact with the surface.

how to use self amalgamating rubber tape. Work your way along the length of the repair area, ensuring that the tape is evenly applied and makes good contact with the surface. In electrical work, insulating strips are used to cover live wires, preventing accidental contact that could lead to short circuits or electric shock In electrical work, insulating strips are used to cover live wires, preventing accidental contact that could lead to short circuits or electric shock

In electrical work, insulating strips are used to cover live wires, preventing accidental contact that could lead to short circuits or electric shock In electrical work, insulating strips are used to cover live wires, preventing accidental contact that could lead to short circuits or electric shock insulating strip. In buildings, they can be seen lining windows and doors to reduce heat loss, improve energy efficiency, and enhance acoustic insulation.

insulating strip. In buildings, they can be seen lining windows and doors to reduce heat loss, improve energy efficiency, and enhance acoustic insulation.Compliance with Fire Safety Regulations

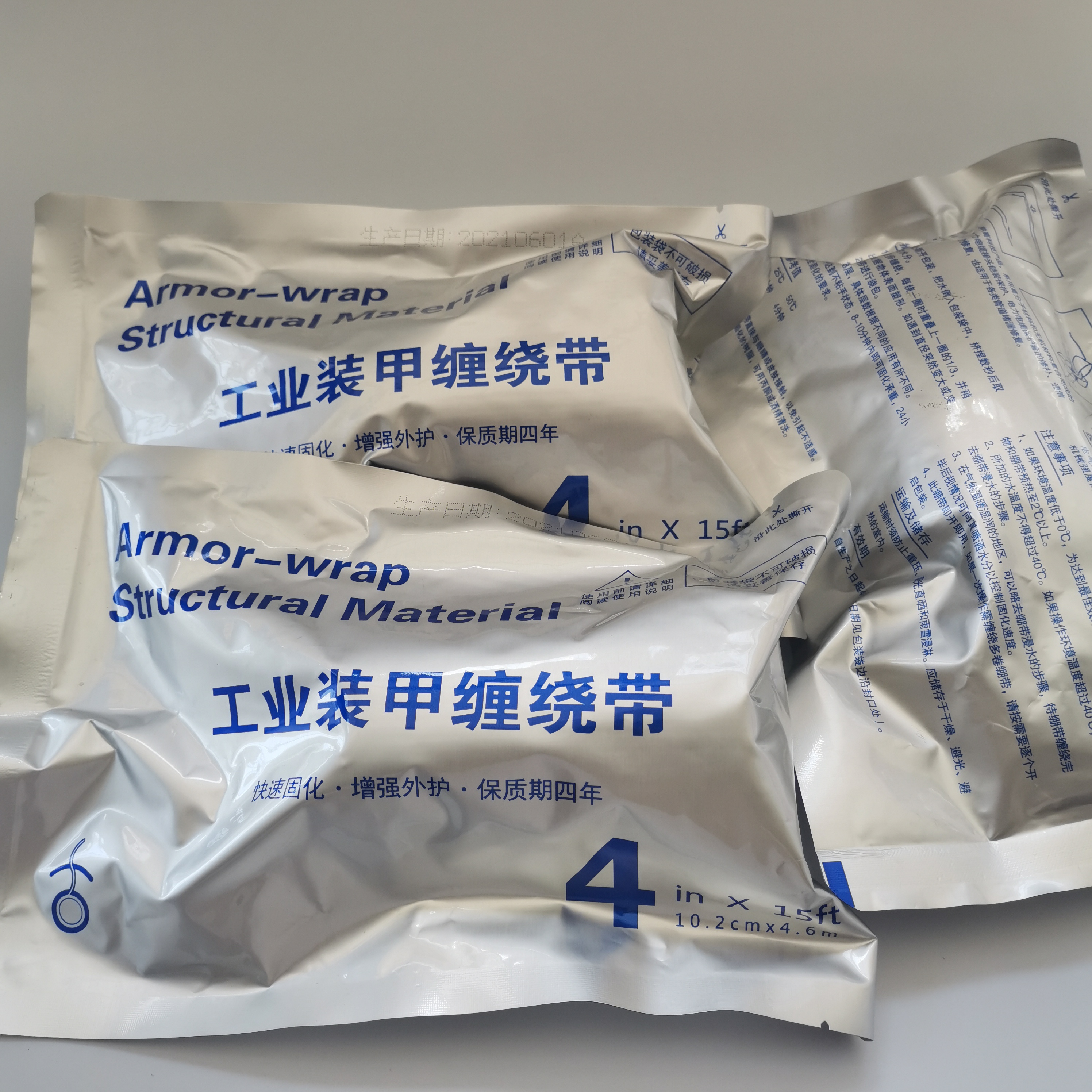

Code: XF-KJD

floor marking tape yellow black. Unlike paint, which can require significant downtime for application and curing, floor marking tape can be installed quickly and with minimal disruption. It is also resistant to wear and tear, withstands heavy foot traffic, and can endure exposure to chemicals, oils, and extreme temperatures, ensuring longevity in industrial settings.

floor marking tape yellow black. Unlike paint, which can require significant downtime for application and curing, floor marking tape can be installed quickly and with minimal disruption. It is also resistant to wear and tear, withstands heavy foot traffic, and can endure exposure to chemicals, oils, and extreme temperatures, ensuring longevity in industrial settings.Repairing split garden hose pipes

In addition to its thermal resistance, silicone insulation tape is highly flexible. This characteristic allows it to conform to irregular surfaces, ensuring comprehensive coverage and effective insulation. Whether wrapping electrical wires, reinforcing connections, or protecting sensitive components, silicone tape adheres securely without the need for additional adhesives. Its self-fusing properties enable it to bond to itself when wrapped, creating a durable and robust protective layer that can withstand vibration and movement.

In the automotive sector, it's used for wire harnessing and general repair work In the automotive sector, it's used for wire harnessing and general repair work

In the automotive sector, it's used for wire harnessing and general repair work In the automotive sector, it's used for wire harnessing and general repair work cloth insulation tape. Even in the arts and crafts world, its adhesive strength and colorful options make it a popular choice.

cloth insulation tape. Even in the arts and crafts world, its adhesive strength and colorful options make it a popular choice.