Gas regulators can be classified into several categories based on their intended application

Gas regulators can be classified into several categories based on their intended application

Applications of Gas Coalescer Filters

2. Pilot-operated Relief Valves These valves use a smaller pilot valve to control the operation of a larger main valve. This design allows for more precise control of pressure and is often used in high-pressure systems.

In recent years, the development of advanced gas filtration technologies has taken center stage in addressing the ever-increasing challenges posed by air pollution. Innovations such as nanomaterials and membrane filtration systems have shown great promise in enhancing the efficiency and efficacy of gas filters. These cutting-edge technologies can target specific contaminants at a molecular level, offering a more tailored approach to air quality management.

Moreover, as countries work towards reducing carbon emissions, natural gas has emerged as a cleaner alternative to coal and oil. Gas distribution stations, therefore, contribute significantly to transitioning energy systems and supporting renewable energy integration, as they can balance supply and demand effectively.

Moreover, gas boosters can enhance the reliability of gas supply systems. Fluctuations in demand, such as during peak usage times in winter months, can create challenges for gas distribution. By using gas boosters, operators can quickly adjust the pressure in response to changing demand, preventing supply shortages and maintaining consistent service levels. This adaptability is vital in creating a resilient energy infrastructure that can weather fluctuations in both demand and supply.

What is a Gas Safety Valve?

Conclusion

In conclusion, pneumatic control valves are indispensable components in fluid control systems across various industries. Their ability to manage the flow of gases quickly and reliably contributes to enhanced efficiency, safety, and productivity in industrial processes. As technology advances, the role of these valves will continue to evolve, integrating with automation systems to meet the growing demands of modern manufacturing and engineering. Therefore, understanding and utilizing pneumatic control valves effectively can lead to significant benefits for any organization reliant on pneumatic applications.

Advocacy and High-Pressure Politics

- Ease of Installation Electric water heaters are generally easier to install than gas models and don't require venting to the exterior of the home. This factor can lead to lower installation costs and greater flexibility in placement.

Conclusion

The deployment of modern gasification equipment offers several benefits. First, it enables the efficient conversion of various feedstocks, which means a wider range of organic materials can be utilized, thus supporting waste reduction initiatives. Second, gasification can significantly reduce greenhouse gas emissions compared to traditional combustion methods, supporting global climate goals. Third, the flexible use of syngas allows for its application in diverse industries, from power generation to the production of transportation fuels.

Blood pressure control devices are invaluable tools in the fight against hypertension. With an array of options available, from manual monitors to smart technology, individuals can choose a device that best fits their needs and lifestyle. Regular monitoring of blood pressure can lead to timely interventions, better management of hypertension, and ultimately a healthier life. As technology continues to evolve, these devices will likely become even more sophisticated, providing crucial support in the ongoing battle against cardiovascular diseases. Embracing these tools is a step toward proactive health management and overall well-being.

Importance of Gas Valves

How Pressure Regulating Valves Work

In today's fast-paced world, stress and pressure have become ubiquitous elements of everyday life. With the challenges posed by work, personal relationships, and societal expectations, many individuals find themselves struggling to cope. This overwhelming pressure has led to the rise of various organizations dedicated to reducing stress and promoting mental well-being. These organizations play a crucial role in raising awareness, providing resources, and offering support to help individuals manage their stress levels effectively.

There are several types of regulating valves, each suited for different applications. The most common types include

Conclusion

3. HVAC Systems In heating, ventilation, and air conditioning (HVAC) systems, pressure reduction devices are vital for regulating refrigerant flow. Proper pressure management is essential for achieving energy efficiency and maintaining optimal temperatures.

Organizations such as the American National Standards Institute (ANSI) and the American Society of Mechanical Engineers (ASME) provide guidelines that help in the selection, installation, and maintenance of relief valves. Compliance with these standards is not only a matter of safety but also a legal requirement in many jurisdictions.

At the core of any pressure reducing regulator is a pressure-sensing mechanism. When the upstream pressure (inlet) exceeds the set point, the PRR automatically adjusts an internal valve, limiting the downstream pressure (outlet) to a predetermined level. This regulation maintains a constant output pressure even when there are fluctuations in the inlet pressure or variations in flow rates. Most regulators incorporate a spring-loaded diaphragm that responds to changes in pressure, creating a reliable feedback loop that maintains stability.

In conclusion, pressure pipes are a fundamental component of modern infrastructure, enabling the efficient and safe transport of fluids. With advancements in materials and technology, the durability and efficiency of pressure pipes continue to improve, catering to the growing demands of urbanization and industrialization. As we look to the future, the role of pressure pipes will only become more prominent, making it essential for engineers, planners, and policymakers to prioritize effective pressure pipe design and implementation in their projects.

How Do Gas Regulators Work?

A gas pressure reducing station typically consists of several components including pressure regulators, valves, measurement devices, and sometimes, heating elements. The primary function is to reduce the high pressure of gas received from the transmission pipelines to the lower pressures required for distribution systems. This process is essential to prevent damage to downstream equipment and to ensure the safety of both the users and the infrastructure.

The Importance of Shut-Off Valves in Industrial Applications

As the world grapples with climate change and environmental degradation, distribution stations are also adapting to minimize their ecological footprint. Many facilities are adopting sustainable practices, such as utilizing energy-efficient systems and incorporating renewable energy sources. Moreover, optimizing transportation routes and using alternative fuels for delivery vehicles can significantly reduce greenhouse gas emissions associated with the distribution process. By aligning with global sustainability goals, distribution stations not only enhance their operational efficiency but also contribute positively to environmental stewardship.

2. Pilot-operated Relief Valves These valves use a smaller pilot valve to control the operation of a larger main valve. This design allows for more precise control of pressure and is often used in high-pressure systems.

Natural gas safety valves are devices designed to control the pressure within gas systems to prevent unsafe conditions. These valves automatically release excess pressure to protect pipelines, equipment, and facilities from damage that could result from over-pressurization. By ensuring that systems operate within designated pressure limits, safety valves contribute significantly to the safe handling of natural gas.

Like their aluminum counterpart, carbon steel frying pans are an excellent conductor of heat. However, they are a more durable and long-lasting option with the proper care, plus they can be used on induction cooktops. They can maintain both low and high temperatures for greater versatility and can cook both delicate foods like eggs and fish as well as sear thick meats like steaks and pork chops. Like cast iron, carbon steel pans require regular seasoning to maintain their non-stick capabilities. However, they heat up faster and are more lightweight, making them a great alternative to cast iron skillets. It is important to note that carbon steel pans are not ideal for cooking acidic foods as they can alter the foods' taste.

Best for: searing a nice crust on meats, such as chops and steak (not good for acidic foods, like tomato sauce, as the iron reacts, imparting a metallic flavor)

using a bacon press. By pressing the bacon as it cooks, you can achieve an ideal crispiness that is difficult to attain through other methods. Moreover, because the bacon press promotes even heat distribution, each slice comes out with a uniform color and texture, making every breakfast feel like a celebration.

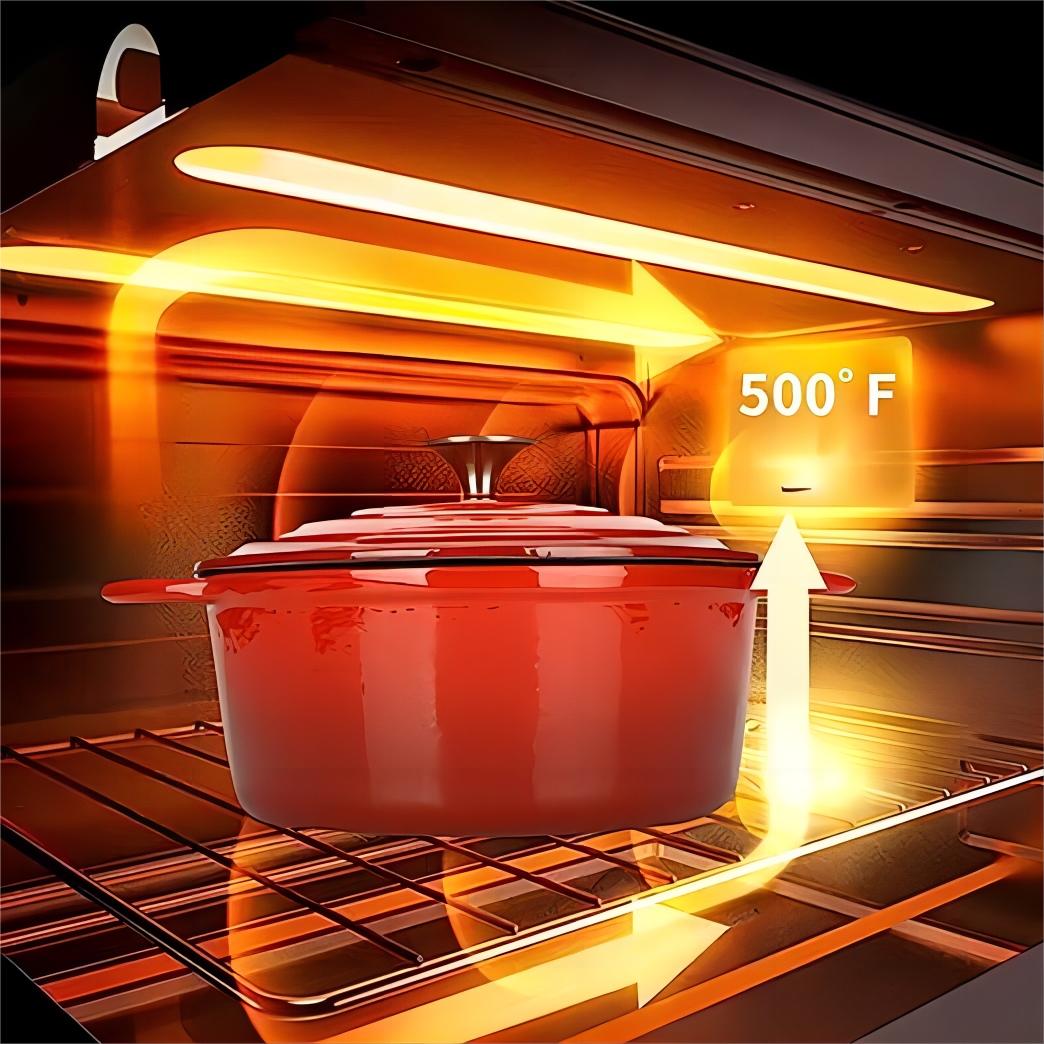

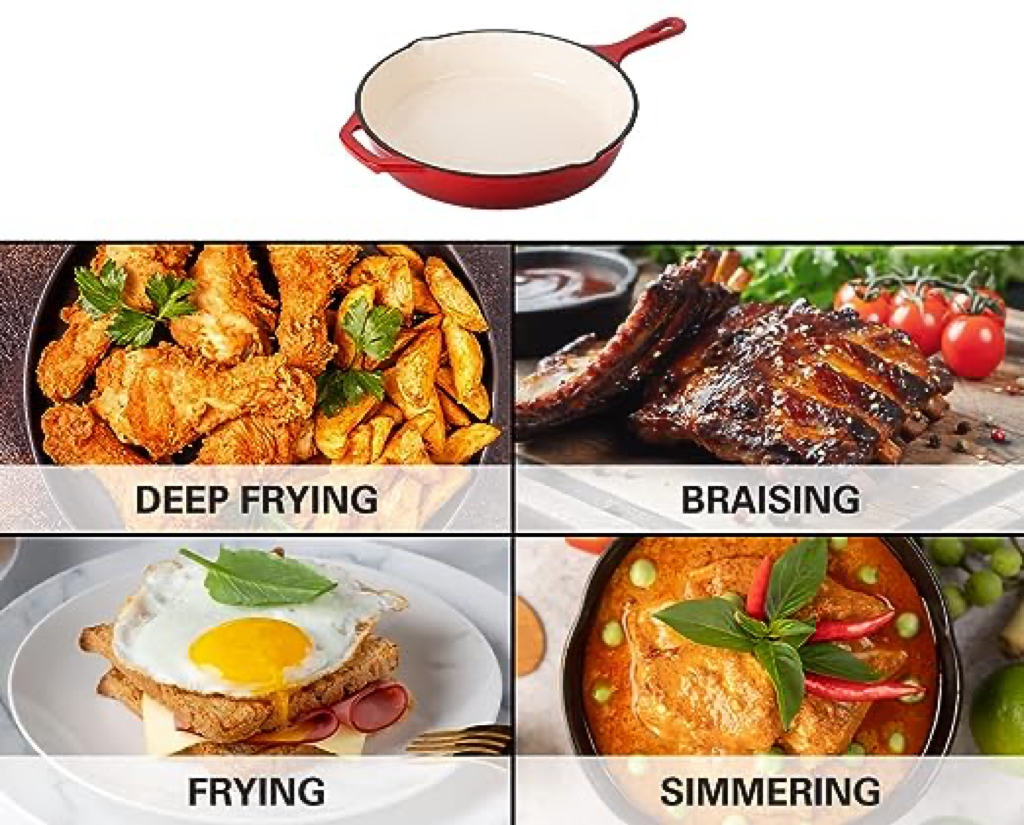

using a bacon press. By pressing the bacon as it cooks, you can achieve an ideal crispiness that is difficult to attain through other methods. Moreover, because the bacon press promotes even heat distribution, each slice comes out with a uniform color and texture, making every breakfast feel like a celebration.All in all, enamel cookware is a timeless addition to any kitchen. Whether you're making hearty soups, hosting hot pot night, or just need a reliable pan, enamel cookware has you covered. Its durability, versatility, and classic style make it a must-have for any home cook. Invest in enamel cookware today and enhance your cooking experience.

Here’s where things may get a little confusing, so we’ll start with the basics. For one, both frypans and skillets have handles attached to its side. One difference is that frypans usually have shorter handles compared to the longer one on skillets. The skillet’s longer handle allows for an easier time to move the pan around the stovetop or to transfer it into the oven for baking.

While it is also rare for skillets to come with a lid, you’ll certainly see it more often than you would on a frypan. The lid is also typically fully opaque so you won’t be able to monitor your cooking as easily. But it sure helps with slow-cooking and braising dishes.

cheap cast iron skillet. Unlike non-stick pans, which require special cleaners and can be damaged by harsh chemicals, cast iron skillets are virtually indestructible. Simply season the skillet with oil after each use, and it will stay in top condition for years to come.

cheap cast iron skillet. Unlike non-stick pans, which require special cleaners and can be damaged by harsh chemicals, cast iron skillets are virtually indestructible. Simply season the skillet with oil after each use, and it will stay in top condition for years to come.Enamel pots are a popular choice for slow cooking and stewing. Enamel coating not only adds a pop of color to the kitchen but also makes the pot easy to clean and maintain.

In addition to their beauty, enamel pots are also known for their durability. The enamel coating not only prevents stains and scratches, it also helps distribute heat evenly for thorough, consistent cooking. This makes enamel pots a reliable and long-lasting addition to your kitchen cookware collection.

large cast iron fry pan. Once heated, the entire surface of the pan becomes hot, ensuring that your food cooks evenly without any hot spots. This makes it perfect for dishes that require long cooking times or multiple ingredients. The even heat distribution also means that you can achieve a perfect sear on your steaks or a crispy crust on your cornbread.

large cast iron fry pan. Once heated, the entire surface of the pan becomes hot, ensuring that your food cooks evenly without any hot spots. This makes it perfect for dishes that require long cooking times or multiple ingredients. The even heat distribution also means that you can achieve a perfect sear on your steaks or a crispy crust on your cornbread.If you're looking to buy cast iron cookware, it's worth researching different brands and reading reviews to make sure you're getting the best value for your money. Some well-known brands offer a variety of cast iron cookware at competitive prices, making it easier to find an option that fits your budget. Additionally, shopping at reputable retailers or online marketplaces can provide a variety of options and potential discounts.

Cooking on a cast iron griddle is a versatile and enjoyable experience, especially when used on an electric stove. Whether you're preparing a hearty breakfast or grilling a steak for dinner, a cast iron griddle gets the job done with ease. Here are some tips for using a cast iron griddle on an electric stove, poaching eggs on the skillet, and cleaning the skillet afterward.

In the United Kingdom, skillets can also refer to larger, deeper, lidded pots or pans with long handles and legs. In the United States, the term refers to a dish constructed from a shallow skillet-shaped metal or ceramic pan and includes cooked diced veggies and meats.