When selecting an electric water heater, consider the following factors

When selecting an electric water heater, consider the following factors

Electric regulating valves play a vital role in modern industrial processes by offering unparalleled control, efficiency, and reliability. Their ability to integrate with automated systems makes them indispensable as industries continue to embrace digital transformation. As technology advances, it is expected that the functionality and applications of electric regulating valves will continue to evolve, further enhancing process management and operational efficiency across various sectors.

The primary function of a safety pressure relief valve is to sense the internal pressure and open when it reaches a set threshold, allowing the excess pressure to escape. This process helps in preventing explosions, equipment damage, and potential injuries to workers present in the vicinity. Once the pressure drops back to a safe level, the valve closes automatically, resuming normal operations.

In Writing and Communication

Pressure Regulating Skids Ensuring Safety and Efficiency in Fluid Transport

- Horizontal Filter Separators These provide a larger surface area for gas-liquid separation and are often favored in systems that process high volumes of gas.

2. Safety Valves Safety is paramount in any industrial operation. Safety valves are critical components that protect the system from pressure surges and potential hazards. They are designed to release excess pressure automatically, preventing damage to equipment or injury to personnel.

How Do They Work?

In summary, filter separators play a critical role in industrial processes by providing an effective means of separating contaminants from fluids. Through their filtration and separation capabilities, these devices not only improve product quality and operation efficiency but also contribute to sustainable practices. As industries continue to innovate and prioritize efficiency and environmental responsibility, filter separators will remain an indispensable component of modern industrial systems. Their evolution will undoubtedly shape future developments, ensuring that they meet increasingly sophisticated processing demands.

There are several types of filters used in natural gas applications, each designed to target specific types of contaminants

Gas pressure regulators find applications in various sectors

One common type of safety valve used in natural gas systems is the pressure relief valve. This valve opens to release excess pressure within the pipeline, preventing structural damage to the system and minimizing the potential for gas leaks. Other types of valves, such as automatic shut-off valves, activate in the event of an earthquake or other disturbances to halt gas flow and prevent catastrophic outcomes.

Moreover, the use of effective filtration systems is not just a matter of operational efficiency; it also has regulatory implications. Many regions have stringent environmental regulations aimed at reducing air pollution. Utilizing high-quality natural gas filters helps operators comply with these regulations, thereby mitigating the risk of fines and enhancing their commitment to environmental stewardship.

Regular maintenance of gas regulators is essential for ensuring their proper performance. Homeowners and businesses should schedule periodic inspections by qualified professionals. Common maintenance tasks include checking for leaks, ensuring that the regulator is free from corrosion, and confirming that all components are functioning correctly.

4. Flexibility These valves can be adjusted to accommodate various pressure requirements, making them versatile for different applications and operational conditions.

- Environmental Compliance Many industries are subject to strict emissions regulations. Using gas coalescer filters helps companies meet these standards by ensuring that only clean gases are released into the atmosphere.

Considerations for Choosing an Electric Water Heater

Applications of Pressure Regulating Devices

Moreover, pressure regulators are designed to handle various conditions, including temperature fluctuations and changes in gas composition. They are built to withstand challenging environments, ensuring that the pressure management is reliable even under adverse conditions.

1. Chemical Industry In the chemical manufacturing process, gases such as hydrogen, nitrogen, and ammonia are often stored in pressure vessels. Their ability to contain gases under high pressure is essential for both the production and storage phases.

Gas pressure reducing valves are widely used in various sectors. In residential applications, they are commonly found in natural gas supplies to households for cooking, heating, and hot water systems. Proper pressure regulation ensures that appliances function safely and efficiently, preventing issues such as incomplete combustion or hazardous gas leaks.

Conclusion

In Technology

The importance of these stations is further highlighted during peak demand seasons, such as winter, when households rely heavily on natural gas for heating. Efficient operation and management of gas distribution stations ensure that supply can meet demand, thus preventing shortages and ensuring safety.

Understanding Pressure Regulation The Role of Pressure Reducing Valves

4. Butterfly Valves Featuring a rotating disc, butterfly valves are compact and lightweight, making them ideal for large volume applications where space is a constraint.

- Efficiency By maintaining a consistent pressure, these valves help to optimize the performance of gas-powered equipment, leading to better fuel efficiency and reduced operational costs.

Conclusion

1. First-Stage Regulators These are used right after the source of natural gas, such as a gas main, to reduce the high pressure from transmission pipelines to a more manageable level for distribution. They can handle high flow rates and pressure, making them suitable for industrial applications.

drifter for rock drill. This innovative tool used high-pressure hydraulic fluid to power a piston that rotated the drill bit, allowing for much greater penetration rates and precision. The hydraulic drifter quickly became the go-to tool for drilling holes in hard rock, paving the way for many of the major engineering projects of the time.

drifter for rock drill. This innovative tool used high-pressure hydraulic fluid to power a piston that rotated the drill bit, allowing for much greater penetration rates and precision. The hydraulic drifter quickly became the go-to tool for drilling holes in hard rock, paving the way for many of the major engineering projects of the time. Applying moderate pressure and maintaining a consistent speed can prevent overheating and premature wear Applying moderate pressure and maintaining a consistent speed can prevent overheating and premature wear

Applying moderate pressure and maintaining a consistent speed can prevent overheating and premature wear Applying moderate pressure and maintaining a consistent speed can prevent overheating and premature wear hardened drill bits. Additionally, using a lubricant like cutting oil can significantly improve the drilling efficiency and bit life.

hardened drill bits. Additionally, using a lubricant like cutting oil can significantly improve the drilling efficiency and bit life.

Hengshui Jrain, completed a lot of FRP fittings for our Australia customer, and they were loaded from workshop today. Hope their travel oversea is joyful.

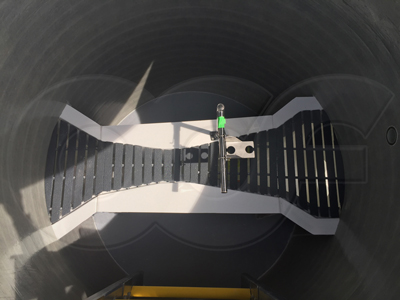

As we all know, there are fiberglass pultruded gratings and fiberglass molded gratings, but how to divide gratings by the shape? Generally speaking, fiberglass grating can be divided to four categories, the most important is divide according to product usage as well as the characteristics of their classification.

According to common usage rules it can be roughly divided to following few categories:

The thread design on some shanks enables a screw-in connection, ensuring a tight fit and preventing slippage during operation The thread design on some shanks enables a screw-in connection, ensuring a tight fit and preventing slippage during operation

The thread design on some shanks enables a screw-in connection, ensuring a tight fit and preventing slippage during operation The thread design on some shanks enables a screw-in connection, ensuring a tight fit and preventing slippage during operation rock drill shank.

rock drill shank.