Applications of Gas Pressure Regulators

Applications of Gas Pressure Regulators

In today's world, the role of pressure pipes is crucial in the efficient transportation of various fluids, from water to industrial chemicals. These pipes are specifically designed to withstand high internal pressures, making them essential for a wide range of applications in municipal, industrial, and agricultural sectors. This article delves into the significance, materials, design considerations, and applications of pressure pipes.

Understanding Gas Pressure Vessels Design, Function, and Safety

While the benefits of intelligent organizers are substantial, it is essential to address the potential drawbacks. The reliance on technology can lead to a disconnect from traditional organizing methods, where analog tools such as paper planners and to-do lists offer a tactile experience that some users find beneficial. Additionally, there’s a risk of becoming too dependent on these technologies, which can lead to challenges when technology fails or when users face information overload. Therefore, a balanced approach that combines intelligent organizing tools with traditional methods may yield the best results.

Gas heat exchangers play a crucial role in various industrial processes, providing efficient means of transferring heat between two or more fluids without mixing them. These devices are epitomized by their ability to maximize energy efficiency, minimize emissions, and enhance overall system performance. With the increasing global emphasis on energy conservation and sustainability, the significance of gas heat exchangers has never been more pronounced.

2. Valves These components control the direction and flow of fluids. Various types of valves, such as control valves, check valves, and isolation valves, are incorporated into the skid design to allow for safe operation and maintenance.

Another challenge facing the LNG industry is the volatility of global energy markets, which can impact the price and demand for LNG. Despite these challenges, the long-term outlook for LNG remains positive, with many countries investing in LNG infrastructure to diversify their energy sources and reduce their dependence on traditional fossil fuels.

Relief valves are critical components in various engineering applications, designed to protect systems from excessive pressure that could lead to catastrophic failures. These valves operate by automatically releasing pressure when it exceeds a predetermined level, ensuring the safety and integrity of equipment.

Pneumatic control valves come in several types, each fitted for specific operational needs

City Gate Station A Nexus of Urban Connectivity

2. Two-stage Regulators These regulators are more complex and are typically used in high-pressure applications. They consist of two distinct stages the first stage reduces the high incoming pressure to an intermediate level, while the second stage further lowers it to the desired output pressure. Two-stage regulators offer greater stability and are ideal for applications requiring precise pressure control.

What is a Gas Regulator?

The Future of Natural Gas Valves

There are several types of natural gas valves, each serving a specific function. Some of the most commonly used valves include

City Gate Station is also increasingly focusing on technological advancements, integrating smart systems to enhance operational efficiency. Innovations such as mobile ticketing, contactless payment systems, and crowd management apps are making the transit experience more convenient for passengers. These technologies not only streamline the purchasing process but also ensure safety and security within the station environment.

Gas pressure vessels are essential components in many industrial processes, as they are used to store and transport pressurized gases safely. These vessels are designed to withstand high pressure and temperature conditions, making them crucial for various applications, such as in the oil and gas, chemical, and manufacturing industries.

Conclusion

3. Temperature Control Since pressure vessels often operate at elevated temperatures, thermal expansion must be considered in the design. Insulation and heat management systems may be necessary to maintain safe operating conditions.

One of the more advanced techniques involves the application of membrane technology, where selective barrier membranes allow only specific gas molecules to pass through while blocking others. This method is particularly useful for separating carbon dioxide and hydrogen sulfide, which are not only undesirable but can also result in environmental penalties if released into the atmosphere.

3. Pharmaceuticals The pharmaceutical industry uses skid mounted systems for processes like formulation and mixing, where cleanliness and precision are paramount. These systems help maintain stringent hygiene standards while offering flexibility in production.

In recent years, the global energy landscape has been undergoing significant transformations, primarily driven by the urgency to address climate change and the transition towards more sustainable energy sources. Within this context, the term Gas Candidate has emerged as a pivotal concept worthy of discussion. The idea of a gas candidate refers to various natural gas resources, technologies, and strategies that can play a crucial role in meeting energy demands while minimizing environmental impact.

In the HVAC (heating, ventilation, and air conditioning) sector, heat exchangers play a pivotal role in controlling indoor climates efficiently. They are used in systems designed to heat or cool air for residential, commercial, and industrial applications. Technologies such as heat recovery ventilators utilize heat exchangers to reclaim energy from exhaust air, thus reducing energy costs while maintaining comfort.

Selecting the appropriate type of pressure relief valve is critical, as it impacts the overall safety and efficiency of the system. Factors to consider include the required pressure range, the medium being handled, and the specific industry standards that apply.

Types of Measurement Systems

There are different types of relief valves — spring-loaded, pilot-operated, and balanced bellows valves, among others. Each type operates on the principle of balancing the force exerted by the gas pressure and the resistance provided by a spring or other mechanism. This ensures that the valve functions precisely at its set pressure, providing reliable protection.

2. Flow Control Valves These valves maintain a desired flow rate of compressed air. They are important for applications where the speed of an actuator needs to be controlled without affecting the overall pressure in the system.

Technological Advancements

4. Pop-off Valves Known for their quick response, pop-off valves open instantly at a specified pressure to prevent damage from sudden pressure surges.

What is a Gas Pressure Regulator?

Gas heat exchangers play a crucial role in various industrial processes, providing efficient means of transferring heat between two or more fluids without mixing them. These devices are epitomized by their ability to maximize energy efficiency, minimize emissions, and enhance overall system performance. With the increasing global emphasis on energy conservation and sustainability, the significance of gas heat exchangers has never been more pronounced.

The Organization of Natural Gas A Global Overview

2. Metering Regulators Positioned downstream of the line pressure regulators, metering regulators are responsible for maintaining a specific pressure before the gas enters individual appliances. They ensure that each device receives the optimal amount of gas needed for efficiency and safety.

The Slurry Pump Blade Factory epitomizes the spirit of innovation and excellence in engineering. By focusing on advanced technology, environmental sustainability, and the diverse needs of its clients, the factory stands as a crucial player in the global industrial landscape. As industries continue to evolve, the need for reliable and efficient slurry pumping solutions will only grow, and the Slurry Pump Blade Factory is poised to meet that demand with precision and expertise. Through its unwavering commitment to quality and innovation, the factory not only supports current industrial practices but also lays the groundwork for a more sustainable and efficient future.

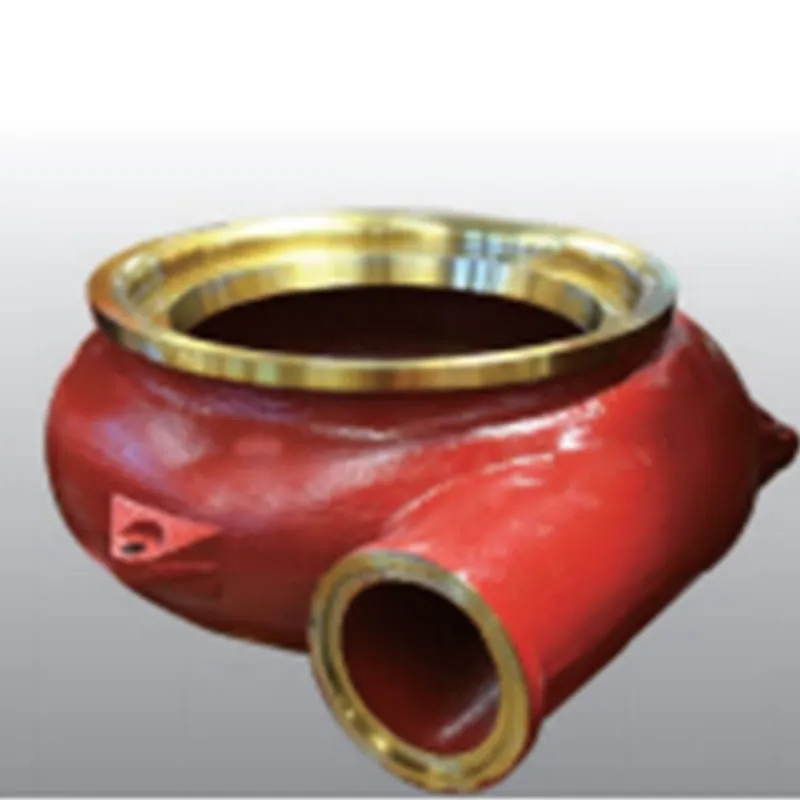

High density slurry pumps are essential components in industrial equipment, especially in the realm of pumps and vacuum devices. These specialized pumps are designed to handle abrasive and high-density slurries, making them ideal for a wide range of applications in industries such as mining, construction, and wastewater treatment.

Meeting Diverse Industry Needs

1. Offshore Oil and Gas Exploration In the oil and gas industry, submarine hammer drilling is crucial for the installation of subsea pipelines and wellheads. The ability to efficiently penetrate the seabed allows for the secure placement of infrastructure that can transport hydrocarbons from extraction points to processing facilities.

There are several types of drainage pumps, each designed for specific applications

In conclusion, the tableau is a versatile and impactful medium that spans time and space, allowing for profound expressions of human emotion and narrative. From its historical roots in painting and theater to its contemporary applications in social media and activism, the tableau continues to resonate with audiences around the world. As we navigate the complexities of modern life, the tableau remains a vital form of artistic expression that encourages reflection, connection, and meaningful dialogue. Through its ability to freeze moments and convey powerful messages, the tableau reminds us of the beauty and complexity of our shared human experience.

2. Lower Operational Costs Given their fuel efficiency and durability, diesel air compressors tend to have lower overall operational costs compared to gasoline-powered models. This makes them a more cost-effective choice for businesses that require reliable air supply.

The DTH hammer operates through a system of compressed air. High-pressure air is directed down the drill string, powering the hammer at the end of the drill bit. The hammer strikes the bit with considerable force, fracturing the rock immediately beneath it. As the bit penetrates further, the broken rock is then cleared from the hole by the same air stream, allowing for continuous drilling without the interruptions often associated with other drilling methods.

5. Noise Reduction Many modern 185 CFM diesel air compressors are designed with noise reduction features. This makes them more environmentally friendly and less disruptive, crucial for use in residential areas or noise-sensitive environments.

The versatility of the Новый 185 CFM air compressor is another critical advantage. It is suitable for a wide range of applications, from construction and landscaping to automotive repair and manufacturing. Its ability to seamlessly integrate with various pneumatic tools makes it a versatile addition to any toolset. This adaptability allows businesses to leverage the compressor for multiple projects, enhancing its value.

The versatility of portable rotary air compressors allows them to be utilized across a variety of sectors

Ongoing missions, including rovers and landers, are equipped with advanced scientific instruments to explore the Martian surface and subsurface. Understanding the effects of Martian low pressure is crucial in assessing the planet's past and present habitability, as well as planning for future explorations.

Advantages of the Fractional Head

Understanding the Basics of Mud Pump Function

تعتبر ضواغط الهواء المحمولة اللولبية من المعدات الأساسية في العديد من الصناعات، حيث تتميز بكفاءتها العالية وقدرتها على تلبية احتياجات متنوعة في مجموعة من التطبيقات. في هذا المقال، سوف نستعرض فوائد ضواغط الهواء المحمولة اللولبية واستخداماتها المختلفة.

As technology advances, the development of even more efficient and durable materials for jaw plates continues to gain attention. Researchers are exploring various alloy compositions and treatments to enhance wear resistance and reduce manufacturing costs. Innovations in metallurgy could lead to the creation of jaw plates that are not only more durable but also lighter, improving the overall efficiency of crushing operations.

Self-priming slurry pump solutions are designed for seamless integration into existing systems and processes. Their compact and versatile design allows for easy installation and operation, minimizing downtime and maximizing productivity.

Third, the structure of the drilling rig:

The drill tool is composed of drill pipe, ball tooth drill bit and impactor. When drilling, two drill rods are used to drill. The reverse air supply structure is composed of a reverse motor, a reverse reducer, and a reverse air supply inverter. The reverse reducer is

В заключение, производство грязных насосов в Кыргызстане - это перспективная отрасль, способная стать двигателем экономического роста. Учитывая уникальные условия страны, производители могут создать инновационные решения, которые будут востребованы не только на внутреннем, но и на внешнем рынках. Заводы, которые осознают важность качества и устойчивого развития, смогут занять свою нишу и способствовать улучшению экологической ситуации, обеспечивая надежное решение для очистки воды и дренажа.

Les matériaux utilisés dans les barres de forage

Производитель грязных насосов Бизнес и технологии в Кыргызстане

In conclusion, the sales of directed drilling rods are set to rise as the industry adapts to the growing demand for efficient and environmentally friendly drilling solutions. The convergence of technology and traditional drilling practices will redefine the future of this market, ensuring that directed drilling remains at the forefront of resource extraction strategies. As firms invest in innovation and sustainability, directed drilling rods will undoubtedly become indispensable tools in the quest for energy security and environmental stewardship.

In the heart of modern industry lies the essential function of pumping materials — a crucial process for various sectors, from mining to wastewater management. One standout example of excellence in this field is the Slurry Pump Blade Factory, a facility dedicated to producing high-performance pumps specifically designed to handle abrasive and viscous materials. This article explores the significance of this factory, its impact on the industry, and the innovative technologies that define its operations.

Cleaning method:

Fill the pump with water

Open the inlet door and clean the clogged part of the pipeline

Plug the leak area and check whether the packing is wet or compressed

What is a Diesel Air Compressor?

Что такое дизельный воздушный компрессор?

One of the key advantages of water well drilling is its ability to provide a self-sufficient source of water. Unlike surface water sources, which can be subject to seasonal fluctuations and contamination, groundwater generally remains stable throughout the year. This stability is particularly critical in agriculture, where access to water can determine crop yields and, consequently, food security. Farmers who drill their own wells can better manage their water resources, applying water more efficiently to their crops and thereby enhancing productivity.

1. Submersible Pumps These pumps are designed to operate submerged in water. They work by pushing water to the surface as opposed to pulling it. This type is commonly used in residential basements and flooded areas due to its efficiency and effectiveness in removing large volumes of water.

The Importance of Mud Evacuation

Submarine Hammer Drilling An Insight into Techniques and Applications

Implementing robust safety protocols and contingency plans can help manage risks associated with downhole drilling. This includes preparing for potential blowouts, managing gas levels, and responding to unexpected geological conditions. The integration of real-time monitoring systems can further enhance safety by providing alerts and data on potential hazards.

Portability is another significant advantage. Unlike stationary compressors, 185 CFM units often come mounted on trailers, making them easy to transport to various job sites. This mobility is particularly beneficial for contractors who work on multiple projects in different locations.

Clean the air filter daily before drilling operations.

\[

3. บริการซ่อมบำรุง สำหรับช่างซ่อมบำรุง คอมเพรสเซอร์ลม CFM 185 เป็นเครื่องมือสำคัญที่ช่วยให้การทำงานเป็นไปอย่างราบรื่น ไม่ว่าจะเป็นการทำความสะอาด การเป่าฝุ่น หรือการใช้เครื่องมือที่ต้องการแรงดันลม