.

4. Adaptability Sliders can be customized to accommodate different types of equipment based on the specific needs of a project. This adaptability means that the same slider can be used for various tasks by swapping out the mounted tools.

The impact of superchargers extends beyond mere convenience; they play a crucial role in the broader adoption of electric vehicles. As more charging stations become available, consumers feel increasingly comfortable transitioning from gasoline-powered cars to electric ones. This shift is essential in combating climate change and working toward sustainable transportation solutions. Additionally, the growing presence of superchargers has prompted other manufacturers to invest in similar technology, leading to a competitive landscape that benefits consumers through improved infrastructure and lower costs.

2. Pilot-Operated Valves These valves utilize a separate pilot valve to control the main valve. They are more complex but are advantageous for larger systems requiring precise pressure management. Pilot-operated valves can handle larger flow rates and are often used in critical applications where accuracy is paramount.

Types of Gas Filters

Applications

The Future of High-Pressure Organizations

A typical pressure reduction station consists of various components, including pressure regulators, filtering systems, metering devices, and safety equipment. The pressure regulators are the heart of the system, managing the reduction of gas pressure by adjusting the flow and minimizing fluctuations. This ensures a consistent supply of natural gas at the required pressure without risking damage to pipelines or end-user equipment.

This hole is visually called a breathing hole. There is a lever made of fine brass in the lower air chamber, the total length is about 5cm, and the rotation performance is very sensitive. The right end of the lever is connected to the center of the rubber membrane, and the left end is adhered to the valve pad and fastened to the intake nozzle, which has a damping effect on the high-pressure petroleum gas that is sprayed. The distance of the left and right ends of this lever from the fulcrum is short left and long right, which are unequal arm levers. Its performance characteristics are: a small change in the force on the right end of the lever will inevitably cause a large change in the force on the left end of the lever. In principle, the amplification of the force is achieved; in effect, the damping effect on the high-pressure gas is increased.

Distribution Stations The Backbone of Energy Delivery

1. Mobility One of the most significant benefits is the ease of movement. A slider enables users to transport equipment across different locations with minimal effort. This mobility is particularly beneficial in environments where tools need to be frequently repositioned, such as job sites or large agricultural fields.

Safety and Storage

A pressure reducer is a mechanical device designed to decrease the pressure of gas or liquid from a high level to a lower, more manageable level. It can regulate the flow and maintain a stable output pressure, regardless of fluctuations in the input pressure. This function is essential in many industries, including healthcare, manufacturing, and energy, where precise pressure control is necessary.

Understanding Gas Separator Filters Importance and Functionality

For larger users, such as industrial plants or community gas systems, LPG is typically stored in bulk tanks. These tanks can hold thousands of liters of gas and are essential for ensuring a continuous supply. Bulk storage tanks come in both above-ground and underground formats and must adhere to stringent safety standards to prevent leaks or catastrophic failures. Additionally, these tanks are equipped with safety valves and pressure release systems to maintain safe operating conditions.

Types of Natural Gas Regulators

Moreover, the LNG sector has significant economic implications. It creates jobs in various stages of the supply chain, from upstream exploration to downstream markets. Additionally, exporting LNG can significantly enhance a country’s trade balance and open new avenues for investment and development.

Benefits and Challenges

2. Plate Heat Exchangers These consist of multiple thin plates arranged to create channels for fluid flow. Plate heat exchangers are known for their compact design and high heat transfer coefficient, making them suitable for various HVAC and refrigeration applications.

Natural gas, when extracted, often contains various impurities, including water vapor, carbon dioxide (CO2), hydrogen sulfide (H2S), and solid particulates. These contaminants can cause operational issues in pipelines, combustion systems, and other equipment, reducing efficiency and increasing maintenance costs. Using natural gas filters is essential to safeguarding the integrity of the gas supply and ensuring compliance with regulatory standards.

The primary advantage of these devices is their ability to empower patients. With the knowledge of their blood pressure readings, individuals can make informed decisions about their health management. Regular monitoring helps in identifying patterns that may indicate worsening conditions, prompting timely medical intervention.

Some PRVs are equipped with additional features, such as gauges and sensors, to provide real-time readings of pressure levels. Additionally, they can be adjusted manually or automatically, depending on the specific requirements of the system.

Furthermore, the integration of gas boosters with renewable energy sources is becoming increasingly relevant. As the world moves towards a greener energy future, the combination of gas and renewables is often seen as a transitional strategy. Gas boosters can facilitate the smooth integration of intermittent renewable energy sources, such as wind and solar, into existing gas networks. By providing a reliable gas supply when renewable sources fall short, gas boosters help stabilize the grid and support the transition to a low-carbon economy.

The operation of gas pressure regulators is not just about efficiency; safety is a paramount concern. Poorly regulated gas pressure can lead to equipment failures, leaks, or even explosions. Therefore, it is crucial for industries to use regulators that meet specific safety standards and regulations.

Regulators are typically positioned at various points throughout the gas distribution system, including at distribution stations, local service lines, and appliances within homes or businesses. They can be classified into two main types pressure-reducing regulators and automatic regulators. Pressure-reducing regulators serve to decrease the pressure of the gas as it flows from high-pressure systems to lower-pressure systems. Automatic regulators, on the other hand, adjust to variations in demand, ensuring a consistent pressure is maintained regardless of fluctuations.

In addition to safety, gas regulators contribute to operational efficiency. By maintaining a constant and appropriate pressure level, they prevent fluctuations that could lead to inconsistent performance of burners, heaters, and other gas-powered equipment. This consistency allows for optimized combustion processes, resulting in better fuel efficiency and reduced emissions. Industries can thus achieve their environmental targets while saving on energy costs, making gas regulators a smart investment.

Moreover, coalescing filters contribute to improved data quality and integrity. In many business intelligence applications, high-quality data is paramount for effective decision-making. By leveraging coalescing filters to maintain clean, concise data sets, organizations can ensure that their analytical insights are based on the most accurate and relevant information available.

Despite its numerous benefits, the transition to a Smart Regulator model is not without challenges. Data security and privacy concerns are paramount, as the increased reliance on data necessitates robust cybersecurity measures to protect sensitive information. Additionally, there is a need for regulators to build the necessary skill sets to interpret and leverage complex data analytics effectively.

Gas safety valves generally operate using a mechanical mechanism that involves pressure sensing. When the normal pressure of gas diminishes beyond a preset threshold—often due to a leak—the valve automatically closes. This action effectively prevents the escape of gas into the atmosphere. Modern gas safety valves can be equipped with various technologies, including electronic sensors and alarms, to enhance their reliability and responsiveness.

At their core, pressure reducing regulators operate on the principle of controlling the flow of fluids through a system. They accomplish this by utilizing a mechanism that adjusts the valve position based on the output pressure readings. Typically, a diaphragm is employed, which responds to the changes in output pressure. When the output pressure drops below a set threshold, the diaphragm moves to open the valve, allowing more fluid to flow through and thus increasing the pressure. Conversely, if the output pressure rises above the desired level, the diaphragm closes the valve to reduce flow and bring the pressure back within acceptable limits.

Types of Natural Gas Pressure Regulators

In conclusion, natural gas filtration plays a vital role in ensuring the quality, safety, and efficiency of natural gas as a primary energy source. As the energy sector evolves, continuous improvements in filtration technologies will be essential in meeting global energy demands while adhering to environmental standards. By prioritizing clean natural gas production, the industry can contribute to a sustainable energy future for generations to come.

Maintenance of metal door knobs is relatively straightforward, another reason for their popularity. Regular cleaning with a gentle soap solution helps remove dirt buildup and prevents tarnishing. For brass knobs, occasional polishing can restore their luster, while stainless steel knobs typically just require a quick wipe down to keep them looking their best. This ease of maintenance makes them a practical choice for busy homeowners or property managers.

Weather-resistant coatings protect them from corrosion, ensuring longevity even in damp or humid environments Weather-resistant coatings protect them from corrosion, ensuring longevity even in damp or humid environments

Weather-resistant coatings protect them from corrosion, ensuring longevity even in damp or humid environments Weather-resistant coatings protect them from corrosion, ensuring longevity even in damp or humid environments sliding door wheels heavy duty. The rust-proof feature is particularly beneficial for exterior sliding doors that are exposed to varying weather conditions.

sliding door wheels heavy duty. The rust-proof feature is particularly beneficial for exterior sliding doors that are exposed to varying weather conditions.Moreover, basketball has become a vital source of entertainment, with thrilling games that capture the attention of millions. The anticipation of a buzzer-beater shot or a slam dunk can evoke exhilarating emotions, making it a captivating spectator sport. The annual events like the NBA Finals and the NCAA March Madness generate unparalleled excitement, drawing in fans and creating a festive atmosphere. Such events create a sense of unity, where strangers become friends as they cheer for their teams, highlighting sports as a powerful tool for community building.

Aluminum profiles fall into this category because they primarily perform the function of providing support for buildings. You can come up with virtually any type of building component in your mind and aluminum profiles might have a use for them. Though the material is heavily lacking in hardness, it does measure high in machinability. This allows production facilities to transform aluminum profiles to a great extent.

The base, whether it's an Edison screw or bayonet mount, ensures secure attachment to the socket, transforming our homes, workplaces, and public spaces into illuminated havens The base, whether it's an Edison screw or bayonet mount, ensures secure attachment to the socket, transforming our homes, workplaces, and public spaces into illuminated havens

The base, whether it's an Edison screw or bayonet mount, ensures secure attachment to the socket, transforming our homes, workplaces, and public spaces into illuminated havens The base, whether it's an Edison screw or bayonet mount, ensures secure attachment to the socket, transforming our homes, workplaces, and public spaces into illuminated havens cosulet sau bulb cu baza.

cosulet sau bulb cu baza.It is ideal for specific aluminum components prone to extreme wear environments and applications. You may also consider it in window and door applications, which require enhanced electrical insulation.

Most modern building designs may have some floor-ceiling windows.

In winter, they can help retain heat inside your home by providing an extra layer of insulation against the cold weather In winter, they can help retain heat inside your home by providing an extra layer of insulation against the cold weather

In winter, they can help retain heat inside your home by providing an extra layer of insulation against the cold weather In winter, they can help retain heat inside your home by providing an extra layer of insulation against the cold weather windows roller. This not only saves money on energy bills but also reduces your carbon footprint.

windows roller. This not only saves money on energy bills but also reduces your carbon footprint.In conclusion, thermal break aluminium profiles represent a significant advancement in building technology, combining aesthetics with performance. They not only help builders and architects design energy-efficient structures but also address critical issues related to thermal comfort and condensation. As the construction industry increasingly prioritizes energy efficiency and sustainability, the integration of thermal break systems in aluminium profiles is expected to become more widespread, offering a compelling solution for eco-friendly building practices. This innovative technology not only enhances the functionality of the building envelope but also aligns with the global commitment to reduced energy consumption and environmental responsibility.

In ancient societies, spear-making was a crucial skill for survival, hunting, and war. Traditional spearheads were made from materials such as stone and bronze; however, the advent of cast iron during the Iron Age significantly transformed their construction. The casting process allowed for more intricate designs and larger production volumes, thereby providing warriors with a reliable and effective tool for combat.

In addition to its security features, a lockable box also provides convenience and accessibility. With a key or combination lock, you can quickly access your items whenever you need them, while keeping them protected when not in use. Some models even come with digital locks or biometric scanners for added security.

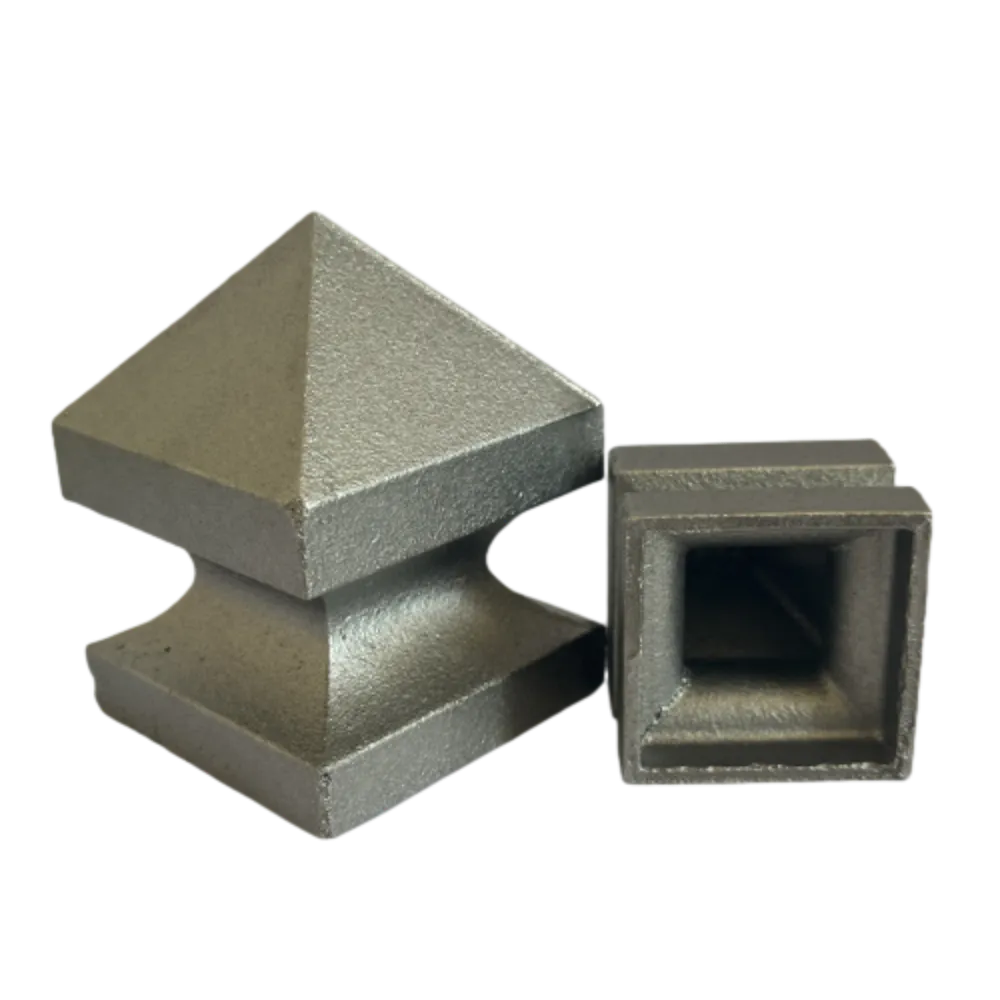

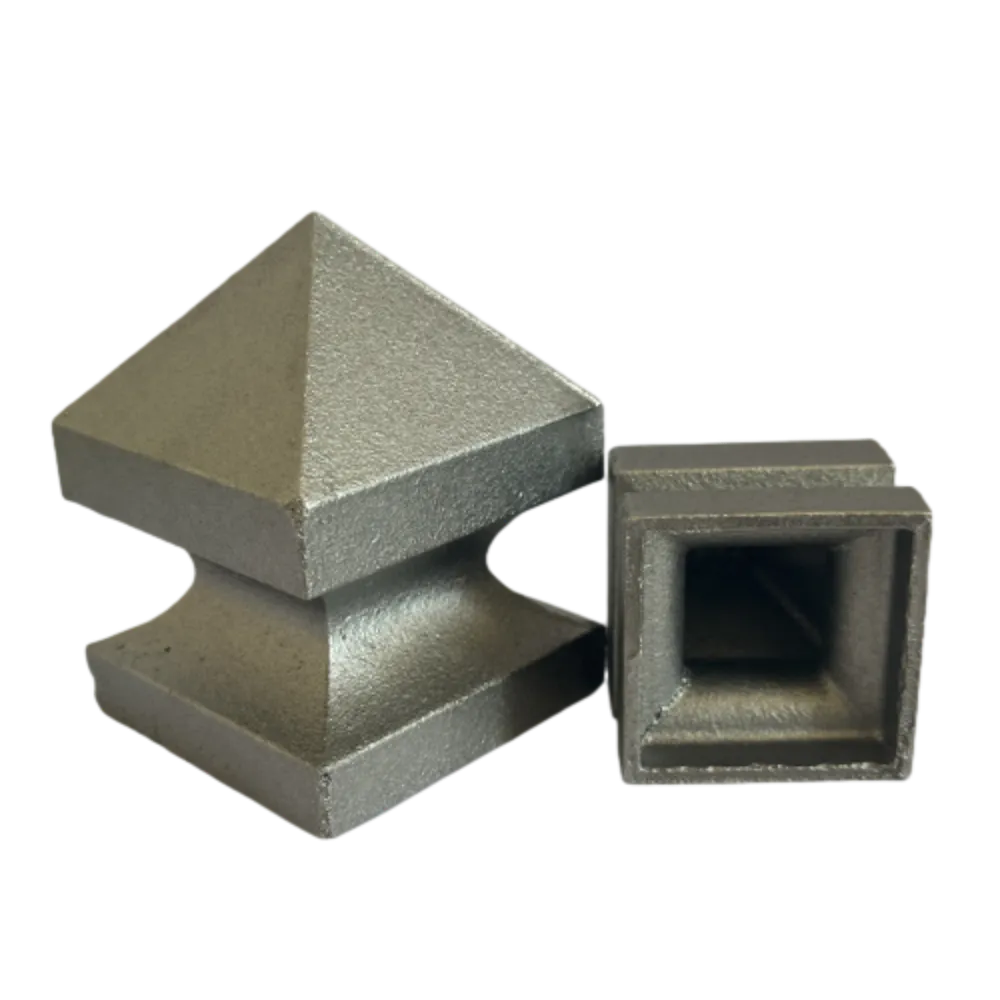

Not merely the component for joining panels together, metal fence posts are also the primary anchors for any installation. By acting as a fence’s “feet,” posts provide stability and security necessary to keep the panels firmly in place. Their height can vary to accommodate whichever panel height you’ve chosen. Matching the post to the panel is essential. These components rely on 2″ square tubing and are visually distinct from the panels. To anchor iron safety fence panels to their corresponding posts, special hardware called a “sleeve,” or a “bracket” attaches the top and bottom rails to the post. Then they’re permanently attached using either screws or a weld.

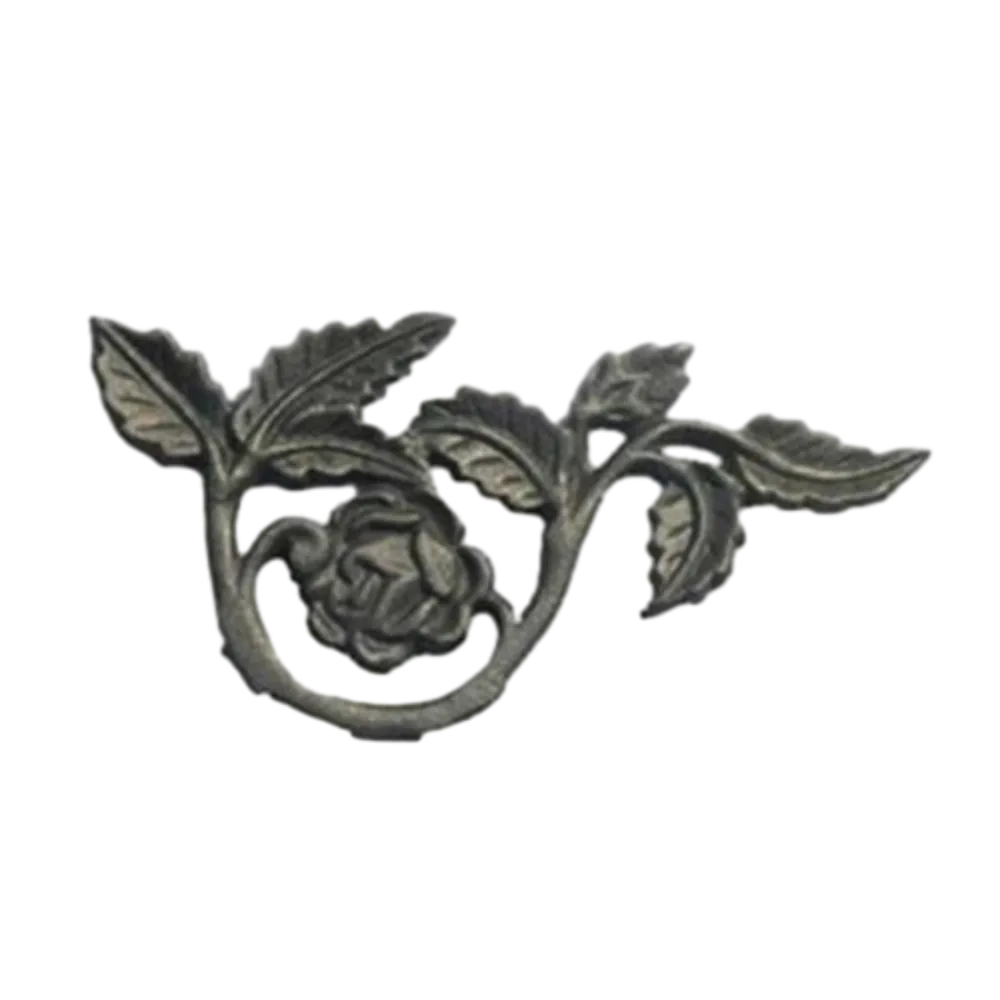

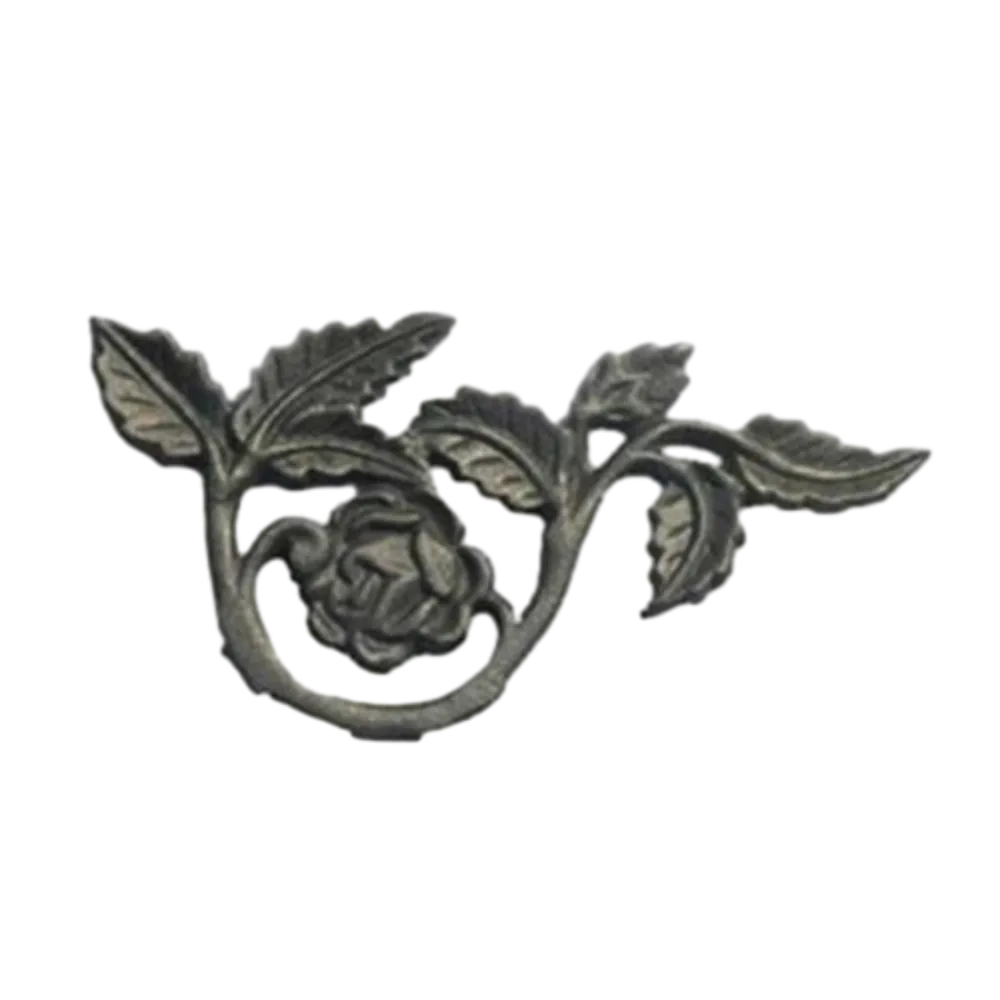

Cast iron ornaments are more than mere decorative accents; they are enduring symbols of craftsmanship and tradition. Crafted with precision and attention to detail, each piece showcases the mastery of skilled artisans, echoing the rich heritage of centuries past. Whether adorning a gate, fence, or interior space, these cast iron ornaments exude a sense of refinement that transcends fleeting trends.

Clean the window screens regularly: The window’s surface is susceptible to collecting dirt, dust, and grime, making it appear lifeless and gloomy. Use a gentle soap or glass cleaner, water solution, and a microfiber cleaning cloth to clean the door’s surface. Avoid using harsh chemicals or abrasive cleansers because doing so can ruin the door’s finish.

stainless steel barn door handles. Most handles come with all the necessary hardware and instructions, making it a simple process to attach them to your door. With just a few basic tools and some patience, you can have your new handles installed and functioning in no time.

stainless steel barn door handles. Most handles come with all the necessary hardware and instructions, making it a simple process to attach them to your door. With just a few basic tools and some patience, you can have your new handles installed and functioning in no time. screen door wheel replacement. Begin by attaching the wheel assembly to the bottom of the screen door, making sure it is aligned with the track. Use the provided mounting screws to secure the assembly in place. Tighten the screws securely, but avoid over-tightening, which can strip the threads.

screen door wheel replacement. Begin by attaching the wheel assembly to the bottom of the screen door, making sure it is aligned with the track. Use the provided mounting screws to secure the assembly in place. Tighten the screws securely, but avoid over-tightening, which can strip the threads.