Principles of Gas Heat Exchangers

Principles of Gas Heat Exchangers

Understanding Pressure Reducing Regulators A Comprehensive Overview

Natural gas heat exchangers are integral to the efficient functioning of energy systems, contributing to the effective management of thermal energy. As technological advancements continue to reshape the landscape of energy production and consumption, these devices will play an increasingly critical role in achieving energy efficiency and sustainability. Investing in innovations related to heat exchangers will not only enhance the performance of natural gas systems but also support the transition towards a more sustainable energy future.

When selecting a pressure regulator, various factors need to be considered, including the type of fluid (liquid or gas), the required flow rate, the inlet and outlet pressure ranges, and the material of construction. For example, corrosive fluids may necessitate regulators made from specialized materials to prevent degradation. Additionally, factors such as temperature, humidity, and the presence of particulates can affect regulator performance, so it's important to choose one that is designed to withstand the specific conditions of your application.

A gas pressure reducer, often referred to as a pressure regulator, plays a crucial role in the safe and efficient handling of gases in various applications, ranging from household appliances to complex industrial processes. By maintaining a consistent outlet pressure regardless of fluctuations in the inlet pressure or varying flow rates, these devices ensure optimal performance and safety in gas utilization.

How Gas Pressure Regulating Valves Work

Shut-off valves are crucial components in various industrial applications, serving a fundamental role in the control and regulation of fluid flow. These valves are designed to either completely stop or allow the passage of liquids and gases within a system. Their functionality is not only vital for operational efficiency but also for ensuring safety and environmental protection.

In various industrial settings, the safe handling and management of gas are paramount to prevent accidents and ensure the well-being of personnel. One critical component that plays a vital role in this regard is the gas safety valve. This device not only helps maintain operational efficiency but also prevents potentially hazardous situations that could lead to catastrophic failures.

A precision voltage regulator is an electronic device that maintains a constant output voltage level despite changes in input voltage and load conditions. These regulators are designed to deliver high accuracy, typically within a few millivolts of the specified output voltage. Unlike standard linear or switching regulators, precision voltage regulators focus on minimizing output voltage variation, often referred to as output voltage ripple, and provide stable performance in environments where fluctuations can significantly impact electronic circuits.

Functions and Importance

Within this system, a filter element plays a critical role in removing solid impurities and contaminants, such as sand and other particles that might hinder the quality of the final product. This filtration process is essential because even a small amount of solid contamination can cause significant damage to downstream equipment, leading to increased maintenance costs and operational downtime.

Safety Considerations

- Environmental Compliance Many industries are subject to strict emissions regulations. Using gas coalescer filters helps companies meet these standards by ensuring that only clean gases are released into the atmosphere.

The installation of a pressure regulating skid is generally a straightforward process, as they are pre-assembled and tested before being delivered to the site. This pre-assembly not only saves valuable time during installation but also ensures that the skid operates efficiently from the get-go. The compact design of skids allows them to be easily integrated into existing systems, making them a practical choice for operators looking to enhance their fluid transport capabilities without extensive overhauls of their infrastructure.

Gas pressure vessels are integral to countless operations across various industries, playing a vital role in the safe storage and handling of gases. As technology advances, the focus on enhancing safety, improving material properties, and ensuring regulatory compliance remains paramount. With the continuous development of innovative designs and safety measures, gas pressure vessels will continue to meet the demands of modern industry while protecting personnel and the environment from potential hazards. Understanding their significance and the complexities involved in their operation is essential for professionals working in these fields, ensuring safe and efficient processes for years to come.

Conclusion

- Enhanced Efficiency By effectively removing particulates and moisture, these filters improve the efficiency of downstream equipment, such as compressors and turbines. This leads to reduced energy consumption and operational costs.

Importance in Natural Gas Operations

Yet, it is essential to recognize that these distinctions do not necessitate isolation. Al-faṣl allows for the appreciation of diversity within unity. It emphasizes that while differences exist, they can coexist harmoniously. The challenge for individuals and societies lies in navigating these separations with empathy and understanding, forging connections that transcend boundaries.

One of the primary benefits of having a well-defined business organization is the clarity it brings. Employees are more likely to perform effectively when they understand their roles and how their contributions fit into the larger framework of the organization. For instance, a company with a clear hierarchical structure delineates authority, reducing confusion and minimizing the potential for conflict. In contrast, ambiguous roles can lead to overlaps in responsibilities, inefficiencies in workflow, and ultimately, decreased morale.

Pressure regulating skids are essential components in maintaining the integrity and efficiency of fluid management systems across various sectors. Their modular design, combined with advanced technology integration, facilitates safe, efficient, and reliable pressure control, ultimately contributing to the overall performance of industrial operations. As industries continue to evolve and demand greater efficiency and safety, pressure regulating skids will remain a critical element in the fluid management landscape.

In chemical manufacturing, separators are used in processes such as distillation and crystallization to separate different components of a mixture. For example, in the production of pharmaceuticals, a separator may be used to isolate a specific compound from a mixture of chemicals. This ensures that the final product meets quality standards and is safe for consumption.

Moreover, the use of decompression skids enhances operational efficiency. By ensuring that the decompression process occurs in a controlled environment, operators can minimize downtime and optimize resource extraction. This is particularly important in offshore platforms, where limited access to repair and maintenance can lead to significant production losses if equipment fails.

The organization of natural gas begins with its extraction. It is typically found in underground rock formations and is often associated with other fossil fuels such as oil. The extraction process involves drilling wells, and the gas is collected through pipelines. Once extracted, natural gas is transported via a vast network of pipelines which can span thousands of miles, connecting production sites to markets. This transportation infrastructure is essential for the distribution of natural gas to residential, commercial, and industrial users.

The organization of natural gas encompasses several aspects, including exploration, production, transportation, distribution, and regulation. Each of these components requires a structured approach to ensure efficiency, safety, and environmental compliance. Governments, international organizations, and private enterprises collaborate to create a framework that governs the entire natural gas supply chain.

- Medical Industry In hospitals, pressure regulators are used with oxygen tanks and anesthetic gases, ensuring that patients receive a consistent flow of the correct pressure for safe and effective treatment.

Despite its benefits, the use of natural gas is not without challenges and controversies. Concerns surrounding methane emissions, a potent greenhouse gas released during natural gas extraction and transportation, have prompted calls for stricter regulations and improved management practices. Furthermore, investments in natural gas infrastructure raise questions about the long-term viability of these projects in a future where a rapid transition to renewables is necessary. Critics argue that reliance on natural gas could hinder investments in more sustainable technologies, thus delaying the shift toward a fully renewable energy system.

5. Sealing and Insulation After the installation of new piping, it is crucial to properly seal joints and connections to prevent leaks. Insulating exposed pipes can also help protect against thermal fluctuations, which can lead to condensation and, eventually, mold growth.

The first and foremost consideration when selecting a sheet metal porch roof manufacturer is the quality of their products. High-quality sheet metal roofing materials can withstand harsh weather conditions, including heavy rain, snow, and intense sunlight. Manufacturers that adhere to industry standards and have a reputation for producing durable products should be at the top of your list. Look for certifications and ratings that reflect a commitment to quality, such as ISO certification or ASTM standards compliance.

The Soldering Process

Challenges and Opportunities

Dachabdichtungen für Metalldächer Eine wichtige Wahl für Langlebigkeit und SchutzMetalldächer erfreuen sich in der Bauindustrie großer Beliebtheit wegen ihrer Langlebigkeit, Widerstandsfähigkeit und der ästhetischen Vielfalt, die sie bieten. Um jedoch die Lebensdauer und die Funktionalität eines Metalldaches zu gewährleisten, ist die Auswahl des richtigen Dachabdichtungsmaterials von entscheidender Bedeutung. Insbesondere in Bezug auf Dachabdichtungsmittel, auch bekannt als „Caulks“, gibt es eine Vielzahl von Optionen, die Metalle und deren Eigenschaften berücksichtigen.Was ist Dachabdichtungsmittel?Dachabdichtungsstoffe sind Materialien, die verwendet werden, um Fugen, Risse oder andere Undichtigkeiten auf Dächern zu verschließen. Sie sind entscheidend, um das Eindringen von Wasser zu verhindern und die zugrunde liegende Struktur vor Schäden zu schützen. Insbesondere bei Metalldächern, die aufgrund ihrer Materialeigenschaften spezifische Herausforderungen in Bezug auf Wärmeausdehnung und Kontraktion aufweisen, ist die Wahl eines geeigneten Abdichtungsmittels unabdingbar.Arten von Dachabdichtungsmitteln für MetalldächerEs gibt verschiedene Arten von Dachabdichtungsmitteln, die speziell für Metalldächer entwickelt wurden. Zu den gängigsten gehören1. Acrylat-Dichtstoffe Diese sind einfach zu verarbeiten und eignen sich gut für kleinere Risse und Fugen. Sie sind wasserbasiert und häufig umweltfreundlicher, jedoch können sie in extremen Wetterbedingungen weniger beständig sein.2. Polyurethan-Dichtstoffe Diese Dichtstoffe bieten hohe Flexibilität und Haftung, was sie ideal für Metalldächer macht. Sie sind in der Lage, sich mit den Bewegungen der Metalle während der Temperaturschwankungen auszudehnen und zusammenzuziehen, was ihre Wirksamkeit erhöht.3. Silikon-Dichtstoffe Silikon ist bekannt für seine hervorragende Wetterbeständigkeit und Haltbarkeit. Es ist besonders effektiv gegen UV-Strahlung und extremem Wetter, was es zu einer ausgezeichneten Wahl für Dächer macht, die intensiven Witterungsbedingungen ausgesetzt sind.4. Butyl-Dichtstoffe Diese sind bekannt für ihre hervorragende Haftung und Flexibilität. Butyl-Dichtstoffe sind eine gängige Wahl für die Abdichtung von Fugen und Übergängen auf Metalldächern, insbesondere in Bereichen, die erhöhte Bewegungen aufweisen.Worauf man beim Kauf achten sollteBeim Kauf von Dachabdichtungsmitteln für Metalldächer gibt es mehrere entscheidende Faktoren, die zu berücksichtigen sind- Kompatibilität mit dem Dachmaterial Vergewissern Sie sich, dass der Dichtstoff mit dem verwendeten Metall und anderen Materialien kompatibel ist, um chemische Reaktionen und Austausch zu vermeiden.- Wetterbeständigkeit Wählen Sie einen Dichtstoff, der für die spezifischen Wetterbedingungen in Ihrer Region geeignet ist, um eine langfristige Leistung sicherzustellen.- Anwendung und Verarbeitung Berücksichtigen Sie, wie einfach der Dichtstoff anzuwenden ist, insbesondere wenn Sie die Abdichtung selbst durchführen möchten.- Haltbarkeit und Garantie Achten Sie auf Produkte, die eine lange Lebensdauer und möglicherweise eine Herstellergarantie bieten.Die Investition in hochwertige Dachabdichtungsmittel ist essenziell, um die Integrität und Langlebigkeit Ihres Metalldachs zu gewährleisten. Zudem sichert es den Schutz Ihrer Immobilie vor Feuchtigkeit und anderen Umwelteinflüssen. Wählen Sie sorgfältig und bleiben Sie proaktiv, um dauerhafte Schäden zu vermeiden.

1. Environmental Impact The most significant advantage of using green metal roofing screws lies in their low environmental footprint. By choosing screws manufactured from recycled materials, builders can contribute to reducing waste and conserving natural resources. This aligns perfectly with the increasing demand for sustainable construction practices.

Moreover, many of these factories are committed to sustainable practices. By optimizing their processes to reduce energy consumption and emissions, they are setting new standards in the industry. Factories often engage in sustainable sourcing of materials, ensuring that they work with suppliers who adhere to environmentally friendly practices.

Baret ware tin plate manufacturers are tasked with not only producing high-quality products but also adhering to stringent safety regulations and environmental standards. The food industry demands that every product be safe for consumption, necessitating thorough testing and adherence to guidelines. As consumers become more conscious about the origins of their products, manufacturers are increasingly focusing on sustainable practices, such as using recycled materials and implementing environmentally friendly processes.

For those interested in embracing this trend, finding a tin can costume supplier is easier than ever. A quick online search yields a plethora of options, from Etsy shops to specialized costume websites. Buyers can explore a wide range of styles, allowing them to find the perfect costume that complements their personalities and reflects their creativity.

Historical Significance

Installation and Maintenance

Understanding Galvanized Iron

Many manufacturers are located in industrial hubs such as Hebei, Shandong, and Jiangsu provinces. These regions are strategically important because they have easy access to raw materials and a robust infrastructure for transportation and logistics. Additionally, many Chinese manufacturers maintain relationships with suppliers and distributors, further streamlining the supply chain.

In today's world, the importance of energy efficiency and sustainability cannot be overstated. As climate change continues to pose significant challenges, manufacturers in the construction industry have taken strides to produce innovative solutions to meet these demands. One such solution is the insulation sheet for roofs, which plays a crucial role in enhancing energy efficiency, comfort, and overall building performance. As a roof insulation sheet manufacturer, we understand the critical aspects of quality, innovation, and sustainability in our products.

Tin Can Albuquerque Manufacturer एक व्यापक दृष्टिकोण

In conclusion, tin plate products factories have evolved significantly over the years, transitioning from manual production to advanced manufacturing processes. Their role in various industries highlights their importance in the global market, as they provide essential materials that contribute to safety, efficiency, and sustainability. As technology continues to advance, these factories are poised to adapt and innovate further, ensuring they remain a vital component of the manufacturing landscape.

4. Comprehensive Support Reputable manufacturers provide extensive support to contractors and builders throughout the installation process. This includes technical assistance, training programs, and detailed installation guidelines to ensure that their products are used effectively and safely. Access to knowledgeable representatives can make a significant difference in the successful application of EPDM roofing systems.

Nel 2014, il mercato dei tetti in metallo in Cina ha mostrato un notevole sviluppo, grazie allaumento della domanda nel settore delledilizia e alla crescente consapevolezza dei benefici dei materiali metallici. I tetti in metallo, noti per la loro durabilit, leggerezza e resistenza agli agenti atmosferici, sono diventati una scelta popolare per molte costruzioni, da quelle residenziali a quelle commerciali e industriali.

- Consumers The final customers, including construction companies, plumbers, and home improvement stores, rely on these fittings for their projects.

- Corrosion Resistance The primary advantage of galvanized angle iron is its ability to resist rust and corrosion, thanks to the zinc coating. This makes it suitable for outdoor use or in areas with high moisture levels.

1. Material Quality The quality of the tin is crucial. Suppliers should offer high-grade materials that prevent corrosion and maintain the integrity of the contents.

Importance of Grounding

4. Installation Costs Beyond the cost of the cooling sheets themselves, installation expenses should also be considered. Some materials can be applied by savvy DIY homeowners, while others may require professional installation. Hiring a professional can add to the overall cost but may ensure proper installation and long-term performance.

The Importance of Tin Can with Lid Factories in Modern Manufacturing

Key Benefits

Innovation The market is continuously evolving, with new technologies and production methods emerging. Leading manufacturers invest in research and development to enhance the properties of MGO roof sheets, such as improving their weather resistance and aesthetic appeal.

When looking for a classic rib metal roofing supplier, there are several factors to consider

Versatility is another advantage. Chrome plated plastic name plates can be made in a range of sizes, shapes, and colors, allowing customization to fit the branding needs of any organization. Businesses can easily integrate their logos, taglines, or specific color schemes into the name plates, reinforcing brand identity among clients and visitors.

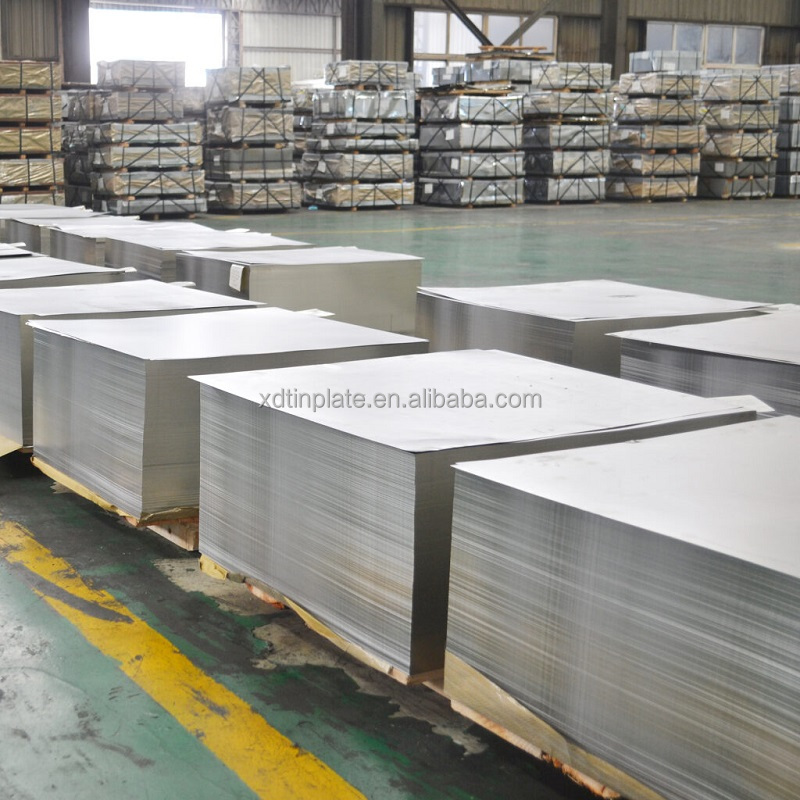

Tin plate is characterized by its lightweight, malleability, and durability. The manufacturing process typically involves the electroplating of steel sheets with tin. This not only protects the metal from rust but also enhances its aesthetic appeal, which is particularly important in consumer-facing products. Tin plate sheet metal is widely utilized for making containers, such as food cans, aerosol cans, and other packaging solutions. Additionally, its use extends to automotive components, electrical appliances, and even decorative items.

Furthermore, the reliability of slip sheets means fewer call-backs and repairs, improving customer satisfaction. As more construction companies adopt these innovative solutions, the overall quality of roofing systems has improved, leading to safer and more durable buildings.

Beyond the quality of products and pricing, the customer service provided by DCBA roof sheet suppliers in China is another area where they excel. Many companies prioritize building strong relationships with their clients, offering technical support, timely communication, and after-sales service. This dedicated approach fosters a sense of trust, encouraging long-term partnerships.

- Construction and Structural Support It is commonly used in the construction of buildings, bridges, and other infrastructures, providing essential support and stability.

Second, advancements in technology have made chrome plating more efficient and cost-effective. Factories are now equipped with modern plating technologies that allow for greater precision and consistency in the plating process, enhancing the overall quality of the finished products.

2. Reputation and Reviews Research customer reviews and testimonials. Reliable manufacturers often have a positive track record and are known for good customer service.

Galvanized iron coils are sheets of iron or steel that have been coated with zinc to prevent corrosion. This galvanization process increases the metal's durability and lifespan, making it an excellent material for construction, automotive, and manufacturing applications. The versatility of galvanized iron coils allows them to be used in roofing sheets, auto bodies, appliances, and various other products.

In addition to aesthetics, printed tinplate sheets offer ample space for essential product information. Nutritional facts, ingredient lists, and cooking instructions can be prominently displayed on the can, helping consumers make informed choices. Regulatory compliance is also simplified, as manufacturers can easily incorporate mandatory labeling directly onto the tinplate.

5. Delivery and Logistics Consider the manufacturer's delivery capabilities. Timely delivery of materials can significantly impact the overall schedule of your roofing project. A reliable manufacturer should offer efficient logistics solutions.

The Importance of Heat Reflective Sheets for Roofs An Insight into Manufacturers

Understanding Roof Slip Sheets

What makes vintage metal lunch boxes so appealing is their craftsmanship. Unlike today's disposable lunch containers, these boxes were designed to last. Made from sturdy metal, they often featured secure latches and handles, making them both functional and durable. The artwork was typically lithographed, which ensured vibrant colors and intricate details that captivated the eyes. Each lunch box was not just a container for food; it was a canvas showcasing the culture and trends of the time.

In conclusion, the synergy between Tin Can Knits, flax yarn, and ethical suppliers underscores the importance of sustainability in crafting. The dedication of both the brand and its partners to responsible practices serves as an inspiration for knitters everywhere. As more individuals discover the joys of working with natural fibers like flax, they contribute to a larger movement towards environmental consciousness in the textile industry. By choosing materials mindfully, knitters can create beautiful, lasting pieces while supporting the planet and local economies. The journey of knitting with flax yarn is not just about the finished project; it is also about the meaningful choices made along the way.

Sa kabuuan, ang mga tagagawa ng PPGI at galvanized steel coil sa Pilipinas ay may mahalagang papel sa pagbuo ng isang maunlad na industriya, at ang kanilang mga produkto ay nagsisilbing pundasyon ng modernong konstruksyon at manufactura sa bansa.

Das Thema der Wellmetall-Dachdecken aus China und Menards-Fabriken

शीट मेटल पैटियो छत की आपूर्ति करने वाले कई प्रतिष्ठान हैं। ये साज-सज्जा कंपनियां न केवल सामग्री प्रदान करती हैं, बल्कि आपके पैटियो की आवश्यकताओं के अनुसार अनुकूलित समाधान भी उपलब्ध कराती हैं। शीट मेटल की एक बड़ी विशेषता यह है कि यह हल्का होने के साथ-साथ उच्चतम गुणवत्ता की स्थिरता को भी प्रदान करता है, जिसे बारिश, बर्फ, और अन्य मौसमीय प्रभावों का सामना करने के लिए डिज़ाइन किया गया है।

2. Low Maintenance Unlike traditional wooden or untreated metal windows, galvanized iron requires minimal maintenance. Regular cleaning and occasional inspections are usually sufficient to keep them in top condition.

In addition, these cans can be fitted with various types of closures and dispensing mechanisms, tailored to the nature of the food product. For instance, manufacturers can design pull-tab lids for easy access to beverages, or use resealable tops for products that are intended to be used over multiple occasions. This adaptability increases consumer satisfaction and fosters repeat purchases.

2. Strength and Stability Galvanized iron boasts impressive strength, making it ideal for applications that require stable, reliable components.

One of the primary reasons behind the surge in personalized tin box manufacturers is the demand for unique packaging solutions. Businesses are constantly seeking ways to differentiate themselves in a crowded marketplace. Personalized tin boxes allow companies to stand out by offering customized designs that reflect their brand identity. Whether it's for product packaging, corporate gifts, or special occasions, personalized tin boxes can be tailored to meet specific needs, featuring custom graphics, colors, and sizes.

6. Reputation and Reviews Research the supplier’s reputation in the industry by checking reviews and testimonials from previous customers. A supplier with positive feedback will often indicate reliability and quality service. Look for case studies or portfolios that showcase their experience and expertise in providing galvanized iron tubes.