Understanding Decompression Skids

Understanding Decompression Skids

Pressure Reducing Regulators (PRRs) are crucial devices in various industrial applications, playing a significant role in controlling gas or liquid pressure. Their primary function is to reduce a higher inlet pressure to a desired, lower outlet pressure, ensuring the safe and efficient operation of systems that require specific pressure levels. This article delves into the design, operation, applications, and advantages of pressure reducing regulators.

The safe use of LPG equipment is supported by strict regulations and safety features. Equipment must be designed to prevent leaks, withstand high pressure, and enable easy maintenance. Various global and local standards guide the design and operational practices of LPG systems, ensuring that both users and the environment are protected from the risks associated with gas handling.

- Residential Use In homes, PRVs are commonly used to regulate the gas supply for heaters, stoves, and hot water systems, ensuring safe and efficient operation.

Conclusion

- Healthcare In medical facilities, pressure reducers are vital for gas supply systems that deliver oxygen and anesthesia. Maintaining proper pressure is crucial for patient safety and effective treatment.

Considerations for Implementation

Moreover, the quality of natural gas directly influences the performance of end-use applications, such as power generation, heating, and industrial processes. Clean gas has higher calorific value, leading to better energy output and reduced emissions. As such, the natural gas industry is increasingly prioritizing filtration strategies to maintain gas quality and meet the demands of a sustainable energy future.

3. Globe Valves Designed for throttling flow, globe valves offer better control than gate valves. However, they have more flow resistance, which limits their use in certain scenarios.

4. Pilot-Operated Valves These valves use a smaller pilot valve to control the larger main valve, providing more precise pressure control, especially in critical industrial applications.

In considering the environmental aspects, it is essential to acknowledge that while gas boosters enhance efficiency, the role they play in broader energy systems must align with sustainable practices. The shift towards cleaner energy solutions necessitates a balance between conventional gas systems and renewable energy technologies. Policymakers and industry leaders must collaborate to ensure that gas boosters and other energy tools are utilized in a manner that supports environmental sustainability.

Shut-off valves find applications across a myriad of industries, including oil and gas, water treatment, pharmaceuticals, and manufacturing. In the oil and gas sector, for instance, these valves are integral to the safe transport of oil and natural gas. They help manage the flow and pressure in pipelines, thus preventing leaks that could lead to environmental disasters. In water treatment facilities, shut-off valves are utilized to control the flow of water through various treatment processes, ensuring that operations run smoothly and efficiently.

In conclusion, city gate stations are not merely transit points; they are key facilitators of urban mobility and economic engagement. Their strategic placement, combined with thoughtful design and the integration of technology, positions them as vital components in the future landscape of urban transportation. As cities strive for sustainability and efficiency in their transit systems, city gate stations will undoubtedly continue to play a crucial role in shaping the way people move and connect within urban environments.

Understanding Gas Pressure Reducers Importance, Functionality, and Applications

In conclusion, natural gas filters are an indispensable component of the natural gas supply chain. They not only facilitate the delivery of clean energy but also enhance the performance and safety of gas systems. As the demand for cleaner energy sources continues to rise, investing in advanced filtration technologies will be crucial for maintaining the integrity of natural gas as a reliable energy source. With ongoing innovations and improvements in filtration methods, the future of natural gas remains bright, paving the way for a more sustainable energy landscape.

A regulating valve, also known as a control valve, is designed to manage the flow of fluids—liquid or gas—throughout a system by varying the size of the flow passage. This modulation can be achieved through various mechanisms, including mechanical, pneumatic, or electronic means. The primary purpose of a regulating valve is to maintain the desired set point of pressure, flow rate, or liquid level, allowing for improved system performance and efficiency.

Gas pressure reducing valves (PRVs) are essential components in various gas distribution systems, ensuring safety and efficiency in the handling of gas pressure. These devices play a crucial role in controlling the pressure of gases from a high-pressure source to a lower, more manageable level suitable for consumption or further processing. This article will delve into the components, functioning, and applications of gas pressure reducing valves, highlighting their importance in industrial and residential settings.

A natural gas safety valve is a critical component in gas distribution systems. It is designed to regulate the flow of gas and prevent excessive pressure build-up within pipelines, appliances, and storage systems. These valves are engineered to automatically close under specific conditions, thereby preventing potential hazards like explosions or leaks. Safety valves come in various types, including relief valves, shut-off valves, and pressure-regulating valves, each serving a unique purpose in managing gas safely.

1. Improved Performance By minimizing data volume, coalescing filters significantly enhance the performance of data processing systems. With less data to handle, databases can respond faster, and applications can operate more smoothly.

What is Skid Mounted Equipment?

The safe use of LPG equipment is supported by strict regulations and safety features. Equipment must be designed to prevent leaks, withstand high pressure, and enable easy maintenance. Various global and local standards guide the design and operational practices of LPG systems, ensuring that both users and the environment are protected from the risks associated with gas handling.

In addition to protecting the system from overpressure, gas safety relief valves also play a crucial role in safeguarding the surrounding environment and people. By releasing excess pressure, the valve helps to prevent the buildup of potentially dangerous gases that could pose serious health risks to those in the vicinity.

4. Back Pressure Regulators Unlike traditional regulators, back pressure regulators control pressure on the inlet side by allowing gas to vent to maintain a set pressure level within the system. They are often used in gas distribution systems.

However, the proliferation of superchargers presents challenges. One issue is the need for standardization across different vehicle manufacturers and charging networks. While Tesla has created a proprietary charging network, other companies have developed different charging standards, leading to compatibility issues for electric vehicle owners. Efforts are underway to establish a universal charging standard which could simplify the charging process for all drivers, regardless of the EV brand they own.

A gas pressure reducer, also known as a pressure regulator, is a mechanical device designed to reduce the high pressure of gas into a lower, more manageable pressure. It ensures that the output pressure remains constant and within a predetermined range, regardless of fluctuations in the input pressure. This capability is vital in many scenarios, as excessive pressure can result in dangerous situations, operational inefficiencies, and equipment damage.

The Importance of Pressure Relief Devices Understanding Mزلقة تخفيف الضغط

The primary function of natural gas filters is to ensure that the gas delivered to end-users is clean and free from harmful substances. By using specialized filtration technologies, these systems are able to maintain the quality of natural gas, thereby enhancing its performance and reducing the likelihood of operational issues.

Moreover, the continuous evolution of pressure control technologies drives innovation in sectors like renewable energy. As industries shift towards greener practices, advanced pressure management systems are becoming crucial in the efficient operation of processes like carbon capture and storage. By maintaining optimal pressure levels in these systems, companies can enhance their sustainability efforts while complying with environmental regulations.

Benefits of Using Pressure Reducing Regulators

In the middle of the regulator is a round rubber membrane, which divides the regulator into two air chambers. There is a spring in the upper air chamber, the upper end is connected with the adjusting screw cover, and the lower end is connected with the rubber film. There is a small hole with a diameter of 0.8 mm at the edge of the upper valve cover, which allows the upper air chamber to communicate with the outside world.

Conclusion

Types of Pneumatic Valves

The Importance of Steel Security Safe Lock Boxes

Unlike handles made from other materials that may require special cleaning products or techniques, stainless steel handles can be easily wiped clean with a soft cloth and mild soap Unlike handles made from other materials that may require special cleaning products or techniques, stainless steel handles can be easily wiped clean with a soft cloth and mild soap

Unlike handles made from other materials that may require special cleaning products or techniques, stainless steel handles can be easily wiped clean with a soft cloth and mild soap Unlike handles made from other materials that may require special cleaning products or techniques, stainless steel handles can be easily wiped clean with a soft cloth and mild soap brushed stainless steel cupboard door handles. This makes them a practical choice for busy homeowners who want to keep their cabinets looking their best without a lot of effort.

brushed stainless steel cupboard door handles. This makes them a practical choice for busy homeowners who want to keep their cabinets looking their best without a lot of effort.

Common decorative elements include ornamental scrollwork, floral motifs, and geometric patterns. The addition of embellishments such as finials, leaves, and other natural forms adds character and flair to the pieces. Blacksmiths often incorporate techniques like forging, welding, and casting to achieve their desired outcomes, resulting in a wide array of textures and finishes.

Despite their names, both cast iron and wrought iron are actually alloys, meaning they contain certain amounts of other materials in addition to iron. Cast iron is usually 2 to 4% carbon and contains small amounts of silicon, manganese and occasionally sulfur and phosphorus. Cast iron is made either by smelting iron ore or pig iron (an intermediate iron ore product) then mixing it with carbon and other metal alloys.

At the beginning of the 20th century, cast iron decorative fences gained popularity due to their low cost and ability to manufacture the many components of ornamental fencing efficiently. Molds are used to create each element of cast iron.

So, when it comes to wrought iron vs. aluminum fences and steel fences, which option is right for you?

For those seeking to add a touch of flair to their architectural designs, cast iron collars offer a perfect solution. These ornate embellishments lend a sense of intricacy and charm to staircases, balconies, and other structural elements, creating a cohesive look that exudes style and sophistication.

Historical Significance

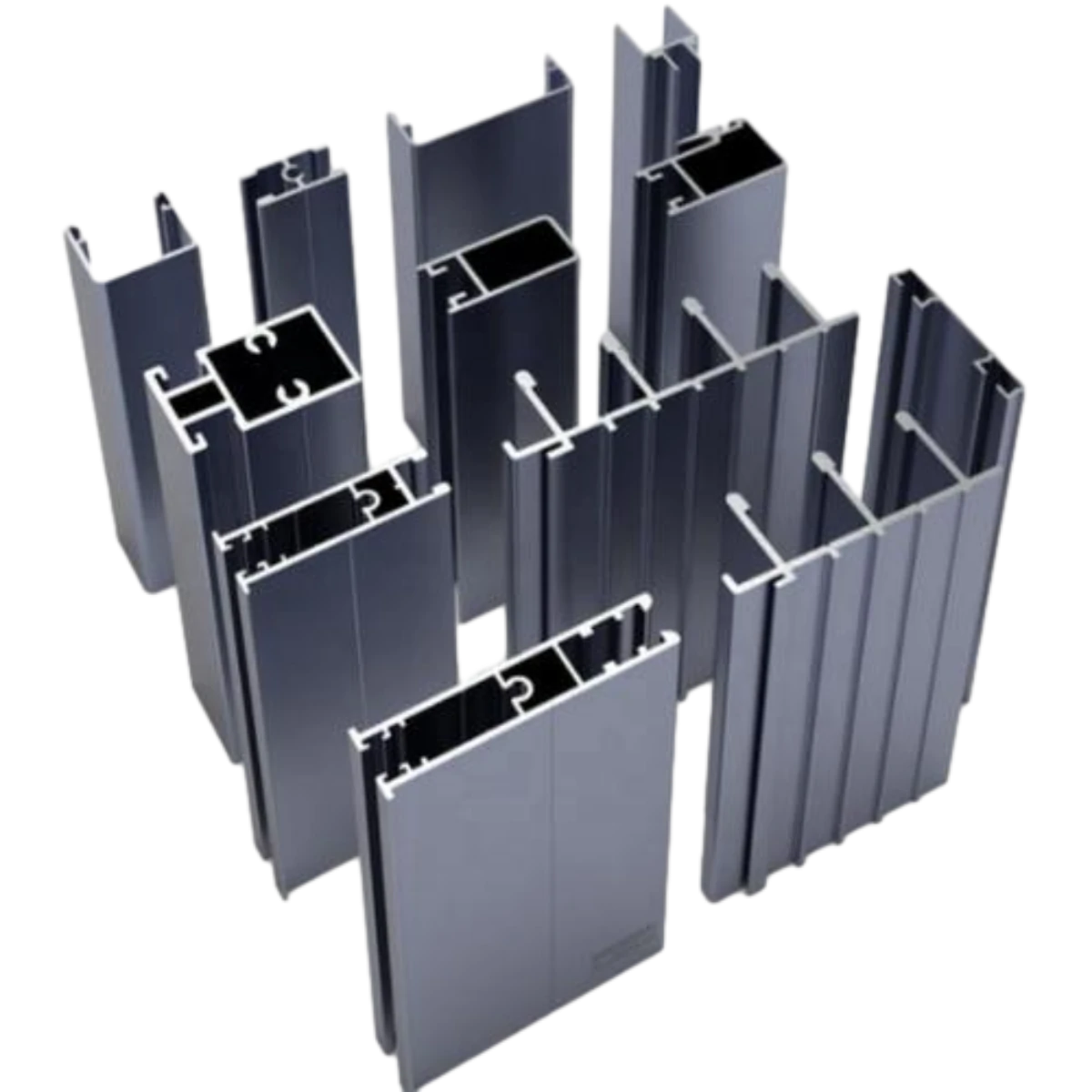

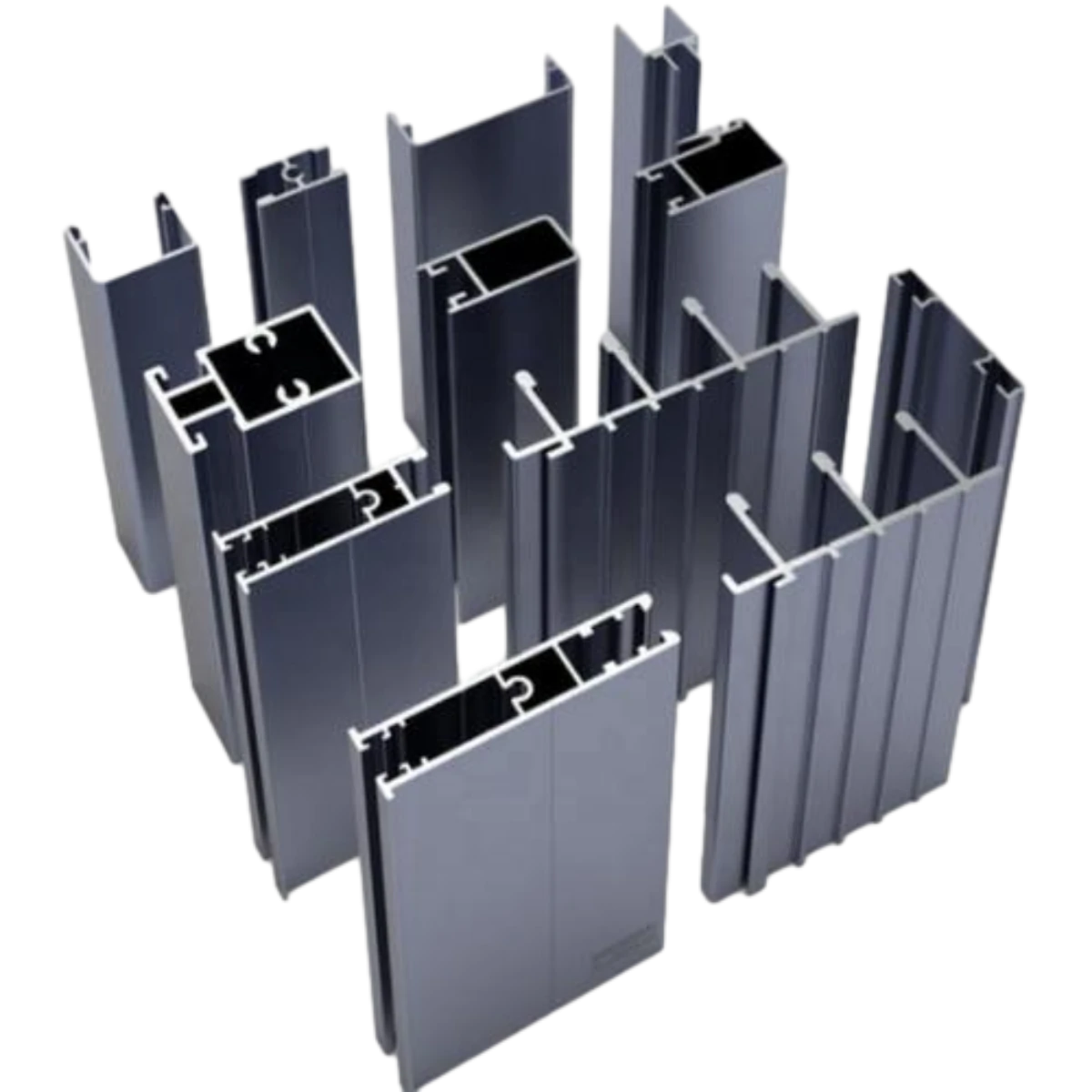

In many cases, when the aluminium profile of doors and windows is deformed and repeatedly pressed, it is found that the maximum wind pressure is seriously inconsistent with the design requirements. The reason is that the wall thickness is not fully considered when selecting the aluminium profiles for door and window. In general, the determination of the wall thickness is combined with the characteristics of the section of the profile, and there is no uniform standard. In general, thin-walled aluminium profiles are not accepted in window and door fabrication. The force-receiving members of the aluminum doors and windows include the frame, the upper glide path, the window fan material, etc. The actual measured dimensions of the minimum wall thickness of these stressed members shall be not less than 1.4 mm for the outer window and not less than 2.0 mm for the outer door. The detection method uses a vernier caliper to perform on-site random sampling inspection of the aluminium profile.

However, these efforts serve to preserve not just the material but also the artistry and history it represents. Over time, the character it acquires transforms your property into something akin to a local treasure.

The sturdy construction and sharp points make it difficult for intruders to climb over or break through, ensuring that your property remains safe and secure The sturdy construction and sharp points make it difficult for intruders to climb over or break through, ensuring that your property remains safe and secure

The sturdy construction and sharp points make it difficult for intruders to climb over or break through, ensuring that your property remains safe and secure The sturdy construction and sharp points make it difficult for intruders to climb over or break through, ensuring that your property remains safe and secure wrought iron decorative fence panels.

wrought iron decorative fence panels.If you do not see signs of rust on your iron fence, or after you have removed all the rust after initially spotting it, it is ideal to apply a coat of wax to the fence exterior. This will create a protective sealant that will help prevent oxidation from occurring in the future, saving you time and money in the long run.

Whether you're seeking to enhance your patio, garden, or poolside retreat, our cast iron furniture for sale offers unparalleled versatility and style. With our extensive selection and commitment to excellence, you can create the outdoor oasis of your dreams, where every moment is infused with beauty and comfort.