2. Pilot-operated Relief Valves These valves utilize a smaller pilot valve to control a larger main valve, providing enhanced performance and accuracy, especially in high-pressure applications.

It serves as a silent reminder to maintain personal space, contributing to public health and safety It serves as a silent reminder to maintain personal space, contributing to public health and safety

It serves as a silent reminder to maintain personal space, contributing to public health and safety It serves as a silent reminder to maintain personal space, contributing to public health and safety

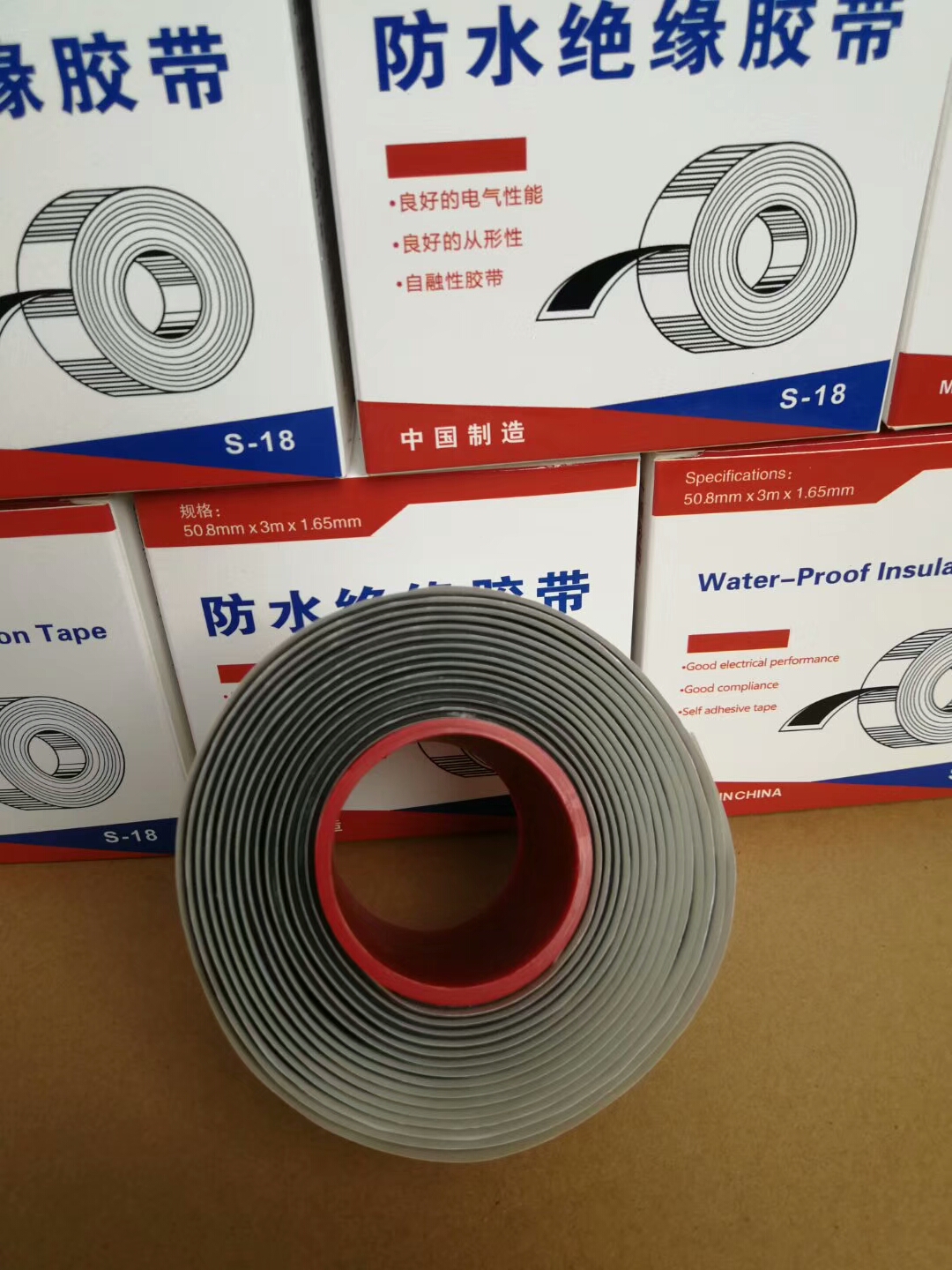

The tape's thickness and backing materials are often customizable, catering to specific application requirements The tape's thickness and backing materials are often customizable, catering to specific application requirements

The tape's thickness and backing materials are often customizable, catering to specific application requirements The tape's thickness and backing materials are often customizable, catering to specific application requirements It can be used to repair damaged insulation on cables or to secure loose connections, providing a temporary or permanent fix It can be used to repair damaged insulation on cables or to secure loose connections, providing a temporary or permanent fix

It can be used to repair damaged insulation on cables or to secure loose connections, providing a temporary or permanent fix It can be used to repair damaged insulation on cables or to secure loose connections, providing a temporary or permanent fix