.

Conclusion

Compliance with safety regulations, such as those outlined by the American Society of Mechanical Engineers (ASME) or the Occupational Safety and Health Administration (OSHA), is essential for ensuring that SRVs function correctly. Failure to comply with these standards can result in severe penalties and contribute to dangerous working conditions.

High-efficiency particulate air (HEPA) filters are also employed in natural gas processing to eliminate solid particulates that might be present. These filters are designed to trap particles as small as 0.3 microns with an efficiency rate of 99.97%, which is vital for protecting downstream equipment from wear and ensuring a clean fuel supply.

The working principle of a pressure reducing device can be understood through its main components the inlet pressure port, the outlet pressure port, and the regulating mechanism

. When a high-pressure fluid enters the device, a sensing element within the regulator detects the pressure and adjusts the mechanism to maintain the desired output pressure. This is typically achieved through a spring-loaded diaphragm or piston that responds to changes in pressure.

Applications

Benefits of Using Pressure Regulating Valves

Types of Gas Regulators

Precision Voltage Regulator Ensuring Stability and Accuracy in Electronic Design

In the energy sector, natural gas pressure reducers play a significant role in various systems, ensuring that gas reaches industrial boilers, turbines, and other equipment at a manageable pressure. Additionally, in the food and beverage industry, reducers are used to control the pressure of gases employed in carbonation processes, ensuring consistency in product quality.

When the outlet pressure exceeds a preset level, the diaphragm moves to close the valve slightly, reducing the flow of gas. Conversely, if the outlet pressure drops below the desired level, the diaphragm will open the valve wider, allowing more gas to flow in. This self-regulating mechanism ensures that the pressure remains stable, adjusting to varying demands.

Gas pressure reducers are integral components in the safe and efficient distribution of gas across various applications. By regulating gas pressure, they not only enhance user safety but also improve the performance of gas-operated appliances and systems. As technology advances, we can expect further innovations in pressure regulation that will provide even greater reliability and efficiency in gas delivery systems. Understanding the role and function of gas pressure reducers is essential for anyone involved in the gas distribution industry, whether in residential, commercial, or industrial settings.

4. Demand Management As energy demand fluctuates throughout the day and across seasons, GPRS can adjust the pressure of gas being delivered to meet consumer needs. This flexibility enables energy suppliers to respond dynamically to changes in demand, optimizing the overall efficiency of the energy supply system.

2. Operational Efficiency Clean fluids contribute to more efficient system operations. By preventing blockages, basket strainers ensure that systems run smoothly, reducing energy consumption and operational costs.

The materials used in constructing gas pressure vessels must ensure durability, strength, and resistance to extreme temperatures and corrosive substances. Steel, for example, is commonly used due to its high tensile strength, while coatings or linings are often applied to protect against specific chemicals.

Selection Criteria

The HVAC industry also benefits from electric regulating valves, as they help in managing air and water flow in heating and cooling systems. By ensuring that the right amount of air or water circulates at the right temperature, these valves play a significant role in energy conservation and operational efficiency.

Applications of Gasification Equipment

Natural gas pressure regulators are essential components within gas distribution systems. Their primary function is to control the pressure of natural gas as it flows from the supply source to residential or commercial users. The pressure of natural gas can vary significantly from the source, which typically operates at high pressure. To use gas safely in homes and businesses, it must be reduced to a much lower, manageable pressure.

In addition to extraction, processing, and transportation, NG equipment is also used in the storage and distribution of natural gas. Storage facilities such as underground caverns and aboveground tanks require specialized equipment to maintain the pressure and temperature needed to store the gas safely. NG equipment such as compressors, regulators, and safety valves are used to control the flow of gas in and out of storage facilities and prevent accidents or leaks.

While gasification technology displays great potential, several challenges remain. High capital costs associated with gasification equipment can be a barrier to entry for many municipalities and businesses. Additionally, the operational complexity and the need for skilled personnel to manage the systems can pose further difficulties.

2. Ball Valves Known for their quick operation, ball valves consist of a spherical disc that can rotate to either allow or block flow. They are versatile and used in applications requiring tight sealing and frequent operation.

Challenges in Gas Distribution

In the realm of digital photography and content creation, filters have become an integral tool for artists and casual users alike. From social media platforms to professional photo editing software, filters allow us to manipulate images and convey emotions that words cannot express. This article will explore the significance of filters, their evolution, and their impact on the way we present and perceive images.

3. Deadweight Pressure Relief Valves These use the weight of a plunger or disk to maintain closure until a predetermined pressure is reached, at which point they open to release excess pressure.

3. Enhanced Safety Maintaining optimal gas pressure through boosting minimizes the risks associated with pressure drops, such as leaks or ruptures in pipelines. A stable pressure ensures a safer transport method.

The Significance of Basket Refining

A natural gas pressure reducing station is designed to lower the pressure of gas being transported through pipelines so it can be safely used in homes and businesses. In the upstream part of the gas supply chain, natural gas is moved through high-pressure pipelines, often under pressures exceeding 1,000 psi. However, for consumers, the gas must be provided at much lower pressures, typically between 4 to 60 psi, depending on local regulations and equipment specifications.

There are various designs and configurations of natural gas filter separators available, each suited for specific applications and operational conditions. The most common types include

Conclusion

In addition to performance, safety is a paramount concern. Gas leaks can lead to explosions and environmental hazards. Properly functioning regulators prevent over-pressurization, which is crucial for preventing accidents.

Conclusion

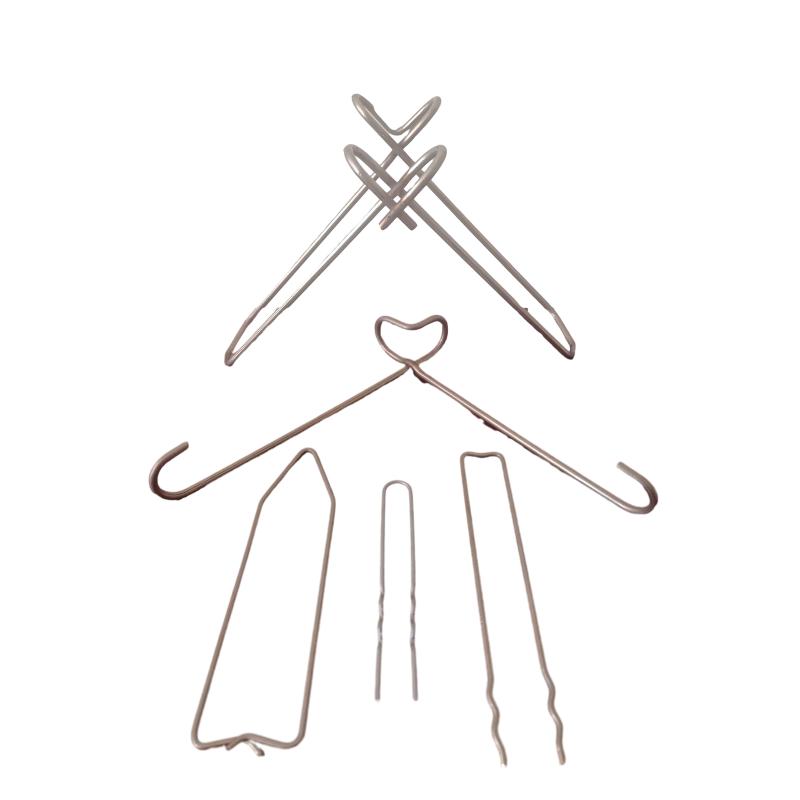

In packaging, black Annealed Wire serves as an effective solution for securing goods. Its flexibility allows it to be easily twisted and tied, forming tight and secure knots that hold items firmly in place. This is particularly useful for packaging irregularly shaped objects that might not fit well into standard boxes or containers. For example, in the shipping of metal parts or machinery, black annealed wire can be used to bundle components together, ensuring they remain intact and organized during transit. The wire’s moderate strength is sufficient to hold these items securely without causing any damage to the surfaces.

Concrete formwork accessories are vital components in the construction industry, ensuring the integrity and durability of concrete structures. From wall ties to rolled steel bars, these accessories play a crucial role in shaping and reinforcing concrete elements. This article delves into essential concrete formwork accessories, including wall ties for concrete, adjustable brick ties, and the benefits of using rolled steel bars.

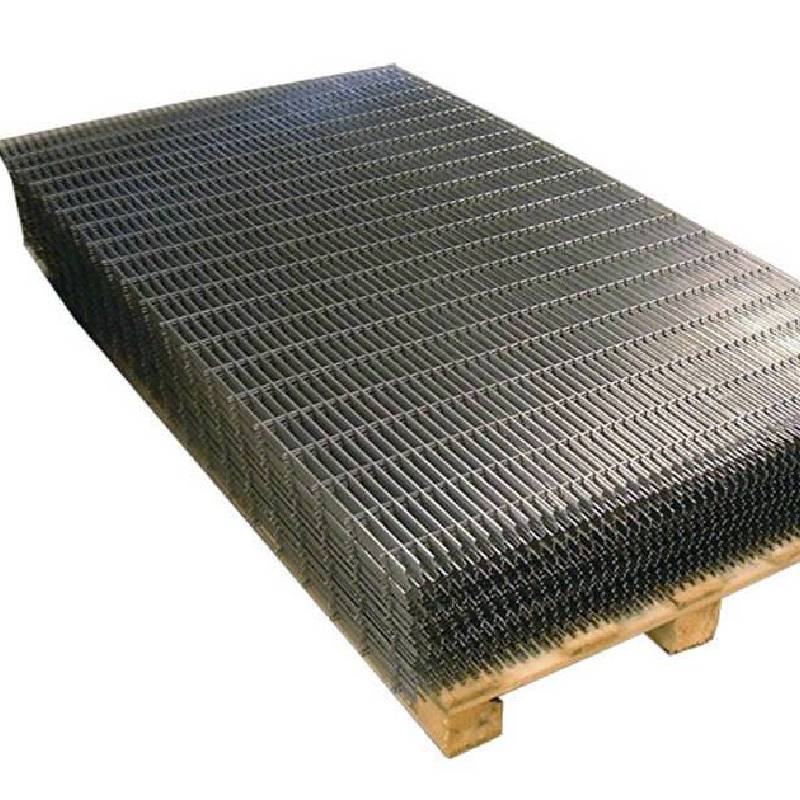

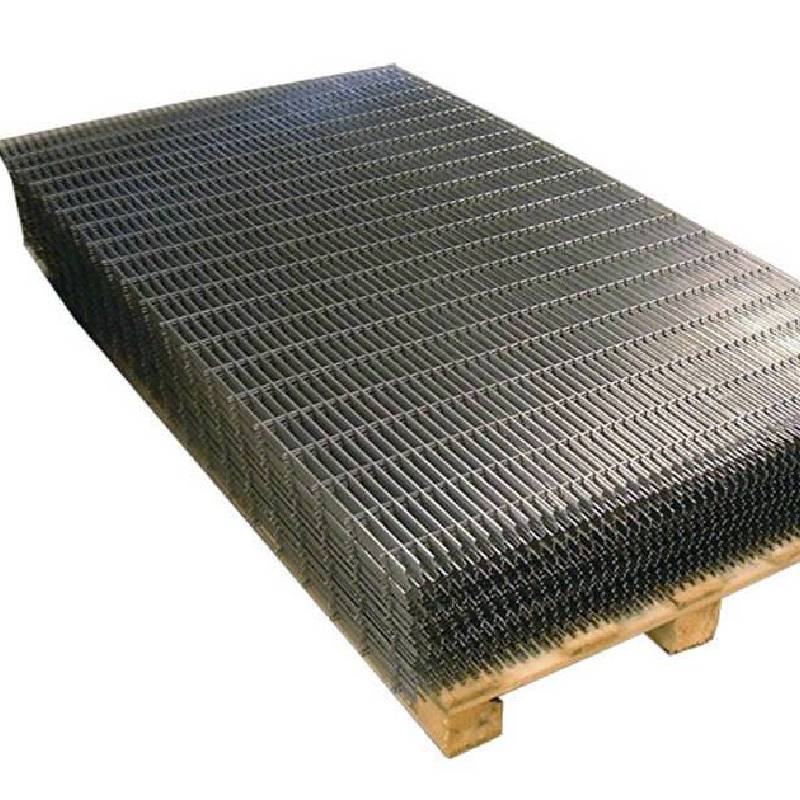

wire mesh manufacturers. Many companies are adopting eco-friendly practices, recycling scrap metal and using energy-efficient machinery. This not only reduces waste but also lowers the carbon footprint of the manufacturing process.

wire mesh manufacturers. Many companies are adopting eco-friendly practices, recycling scrap metal and using energy-efficient machinery. This not only reduces waste but also lowers the carbon footprint of the manufacturing process.

Fiberglass reinforcement is a lightweight and non-corrosive option that is easy to handle and install. It is an excellent choice for projects where weight is a concern or where there is a need for non-metallic reinforcement.

It also enhances the wall's ability to resist overturning, sliding, and out-of-plane forces, especially in areas prone to earthquakes It also enhances the wall's ability to resist overturning, sliding, and out-of-plane forces, especially in areas prone to earthquakes

It also enhances the wall's ability to resist overturning, sliding, and out-of-plane forces, especially in areas prone to earthquakes It also enhances the wall's ability to resist overturning, sliding, and out-of-plane forces, especially in areas prone to earthquakes horizontal joint reinforcement masonry.

horizontal joint reinforcement masonry. They are typically inserted into pre-drilled holes in the masonry, ensuring a snug fit to prevent any movement They are typically inserted into pre-drilled holes in the masonry, ensuring a snug fit to prevent any movement

They are typically inserted into pre-drilled holes in the masonry, ensuring a snug fit to prevent any movement They are typically inserted into pre-drilled holes in the masonry, ensuring a snug fit to prevent any movement steel wall ties. The choice of the right type of wall tie depends on various factors, including the thickness of the cavity, the load-bearing requirements, and the environmental conditions the structure will face.

steel wall ties. The choice of the right type of wall tie depends on various factors, including the thickness of the cavity, the load-bearing requirements, and the environmental conditions the structure will face.