The installation of a natural gas pressure regulator is usually done by professionals who adhere to stringent guidelines and regulations

Natural gas valves come in various types, each designed for specific functions within the gas distribution and usage framework. Some of the most common types include

Natural gas is one of the most widely used sources of energy worldwide, favored for its efficiency and relatively lower environmental impact compared to other fossil fuels. Gas distribution stations are strategically located to facilitate the smooth transfer of gas from high-pressure pipelines to lower-pressure distribution networks. These stations ensure that gas is available for various uses, from heating homes to powering industrial processes and generating electricity.

- Manufacturing In manufacturing processes, especially those involving gas-fired equipment, maintaining a steady gas flow is essential. Pressure reducers improve efficiency in production lines and reduce the risk of malfunctioning machinery.

Understanding Coalescing Filters An Overview

Natural gas regulators operate based on a mechanical design that reacts to changes in gas pressure. The key components of a typical gas regulator include a valve, a diaphragm, and a spring. The diaphragm moves in response to pressure changes, which allows the regulator to increase or decrease the flow of gas based on demand or supply fluctuations.

Environmental Impact

Mounted equipment typically includes a wide range of tools that can be utilized in various fields such as construction, agriculture, and manufacturing. These tools are often fixed onto a slider, which serves as a movable base, facilitating seamless transportation and operation. The slider mechanism allows the equipment to be easily repositioned, making it ideal for tasks that require portability and adaptable configurations.

Types of Natural Gas Regulators

How Gas Pressure Reducers Work

Furthermore, the natural gas market is often influenced by geopolitical tensions, as countries rich in natural gas reserves may leverage their resources for political ends. This can lead to fluctuations in global gas prices and supply disruptions, thereby impacting energy security for many nations.

Furthermore, geopolitical tensions can disrupt the natural gas supply chain. Countries rich in natural gas may find themselves in conflicts over resource management, leading to instability in production and pricing. Thus, establishing robust international cooperation is essential to navigate these complexities and ensure a reliable supply.

Despite its potential, gasification also faces challenges. High capital costs, feedstock variability, and the need for sophisticated technology can hinder widespread adoption. However, ongoing research and development efforts aim to address these issues, making gasification a more viable option for large-scale energy production.

Economic and Environmental Impact

1. Spring-loaded valves The most common type, which uses a spring to hold the valve closed until the specified pressure is reached.

Types of Shut-Off Valves

However, both types integrate feedback mechanisms to continuously monitor output voltage. By comparing the output with a reference voltage, the regulator can adjust its internal resistance (in linear types) or control the switching cycle (in switching types) to maintain a stable output. This feedback loop is critical for achieving the precision that these regulators are known for, often less than 1% deviation from the target voltage.

Conclusion

1. Direct-acting Pressure Reducing Valves These are the simplest form, where the diaphragm directly controls the flow based on the detected pressure.

1. Open/Close Control Simple on/off operation based on threshold settings.

1. Safety High-pressure natural gas can pose significant risks, including explosions and leaks. Pressure reducers help mitigate these risks by ensuring that the gas delivered is within safe operating limits.

3. Equipment Longevity Operating machinery or appliances at the correct pressure helps prolong their lifespan. Excessive pressure can cause wear and tear, leading to expensive repairs or replacements. Gas pressure reducers help in maintaining optimal operating conditions.

However, despite its advantages, there are some challenges associated with CNG. One of the primary obstacles is the availability and accessibility of refueling stations. In many regions, CNG infrastructure is still underdeveloped, leading to concerns about the feasibility of long-distance travel. Additionally, while the production of CNG is cleaner than other fossil fuels, it still involves extraction processes that can have environmental impacts, such as methane leakage during gas extraction and transportation. As such, it is essential to continue refining extraction methods and improving the sustainability of the entire supply chain.

In conclusion, gas pressure regulators are indispensable components in gas management systems. Their ability to regulate pressure ensures safety and efficiency in various applications, from residential heating to industrial processes. As technology advances, these devices continue to evolve, incorporating innovative features that enhance their functionality. Understanding the importance of gas pressure regulators is essential for anyone working with or relying on gas systems, as they ultimately play a critical role in ensuring safety and performance.

Gas pressure vessels are specialized containers designed to hold gases at a pressure significantly higher than atmospheric pressure. The ability to safely store and manage gases under pressure is crucial in various industries, including energy, pharmaceuticals, and aerospace. This article explores the principles behind gas pressure vessels, their construction, applications, and safety considerations.

Conclusion

Pressure vessels are specialized containers designed to hold gases or liquids at high pressure. These structures are critical in various industries, including oil and gas, chemical manufacturing, power generation, and food processing. Understanding the properties, design considerations, and safety measures of pressure vessels is essential for engineers and safety professionals alike.

2. Efficiency Gas regulators contribute to the efficiency of gas appliances. When the gas is supplied at the correct pressure, appliances can operate more effectively, leading to reduced fuel consumption and lower operational costs. This is particularly significant in industrial settings, where even minor inefficiencies can result in substantial financial losses.

Furthermore, consider using a programmable thermostat to regulate heating times, ensuring warmth only when necessary. It is also advisable to keep flammable objects away from the heater and to avoid using extension cords to prevent overheating hazards.

Applications of Gasification Equipment

Economic and Environmental Impact

Safety Regulations and Standards

Moreover, the geopolitical dimensions of natural gas are significant. Many countries are investing in liquefied natural gas (LNG) infrastructure to enhance their energy security and reduce reliance on oil. This shift has implications for international relations, as nations compete for access to natural gas markets. Countries rich in natural gas resources can wield substantial economic and political power, influencing global energy prices and policies.

Applications of Gas Pressure Reducers

regulator. By setting and enforcing standards, regulators help to maintain a level playing field for businesses, protect consumers from harm, and uphold the rule of law.

regulator. By setting and enforcing standards, regulators help to maintain a level playing field for businesses, protect consumers from harm, and uphold the rule of law.In addition to tying rebar, galvanized iron wire is also used to secure other structural materials during construction. For instance, it can be employed to hold together steel beams, mesh, and other metallic components that are integral to a building’s framework. Its high tensile strength allows it to withstand significant weight and pressure, making it ideal for holding large and heavy materials in place. The zinc coating not only protects the wire itself from rusting but also helps prevent any potential corrosion-related damage to the materials it binds.

3 8 compression spring. Its ability to store and release energy efficiently is utilized in equipment such as presses, where force must be applied and then released in a controlled manner. In electronics, these springs provide the necessary pressure for electrical contacts, ensuring reliable connectivity.

3 8 compression spring. Its ability to store and release energy efficiently is utilized in equipment such as presses, where force must be applied and then released in a controlled manner. In electronics, these springs provide the necessary pressure for electrical contacts, ensuring reliable connectivity. welded steel mesh price. Many suppliers offer discounts for large orders, so buying more mesh at once can reduce the overall cost per unit. However, it is important to carefully measure your needs and only order what you need to avoid overpaying for unused material.

welded steel mesh price. Many suppliers offer discounts for large orders, so buying more mesh at once can reduce the overall cost per unit. However, it is important to carefully measure your needs and only order what you need to avoid overpaying for unused material.Another advantage of small sign stakes is their cost-effectiveness. Compared to more permanent signage options, small sign stakes are relatively inexpensive and can be purchased in bulk for even greater savings. This makes them an affordable option for businesses, organizations, and individuals looking to communicate messages effectively without breaking the bank.

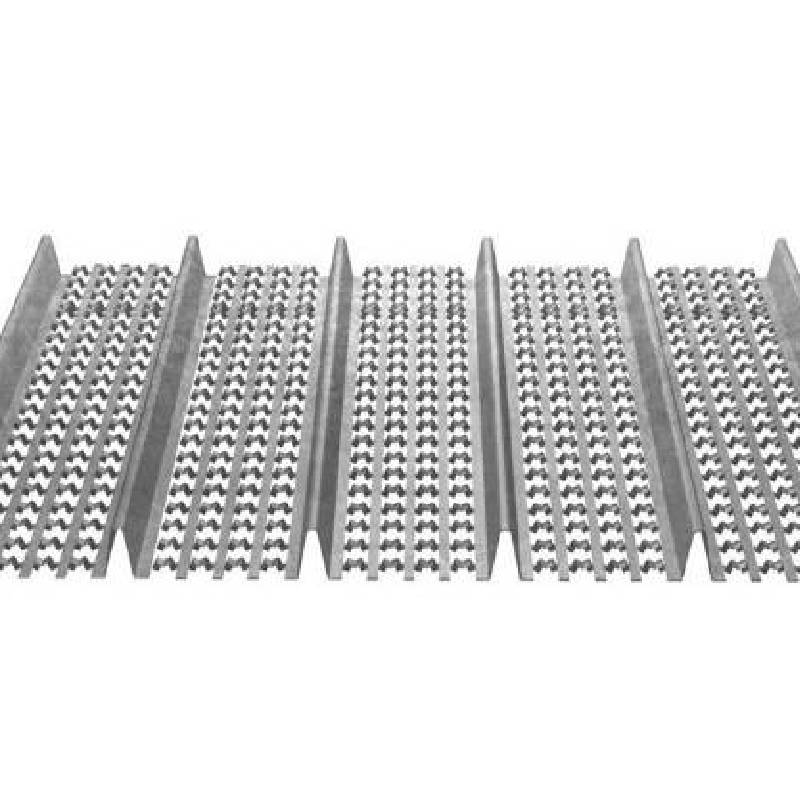

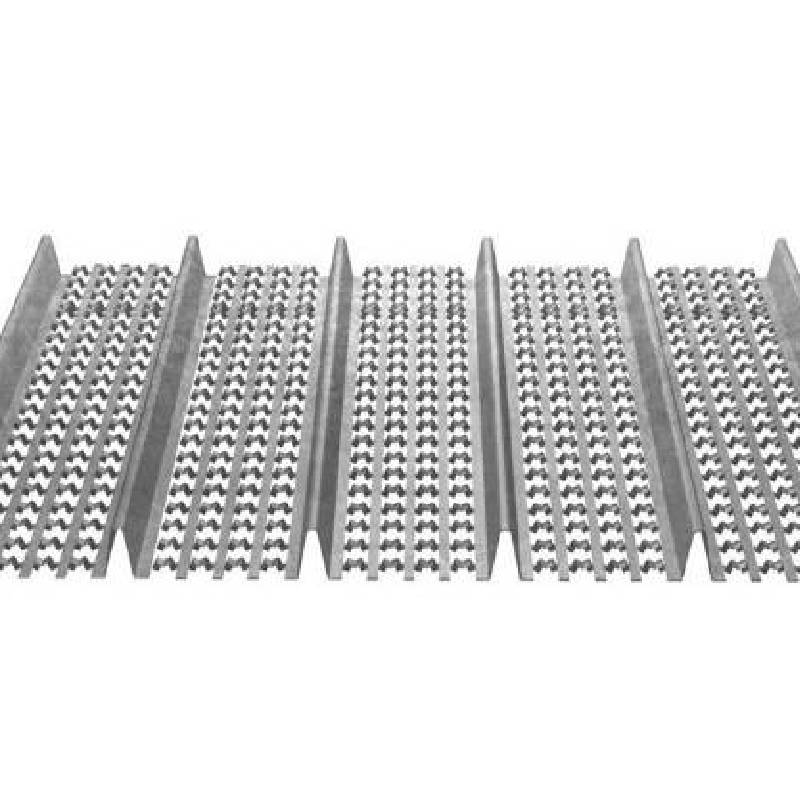

metal rib lath. It can be easily cut and shaped to accommodate intricate architectural features, allowing for a wide range of creative possibilities. Its lightweight nature simplifies handling and installation, reducing labor costs and project timelines.

metal rib lath. It can be easily cut and shaped to accommodate intricate architectural features, allowing for a wide range of creative possibilities. Its lightweight nature simplifies handling and installation, reducing labor costs and project timelines. Their simple, straightforward design and natural color palette blend seamlessly with the surrounding environment, creating a harmonious and aesthetically pleasing appearance Their simple, straightforward design and natural color palette blend seamlessly with the surrounding environment, creating a harmonious and aesthetically pleasing appearance

Their simple, straightforward design and natural color palette blend seamlessly with the surrounding environment, creating a harmonious and aesthetically pleasing appearance Their simple, straightforward design and natural color palette blend seamlessly with the surrounding environment, creating a harmonious and aesthetically pleasing appearance cow panel fence. Whether used to outline a garden or to define a property line, cow panel fences add a touch of country elegance to any outdoor space.

cow panel fence. Whether used to outline a garden or to define a property line, cow panel fences add a touch of country elegance to any outdoor space.

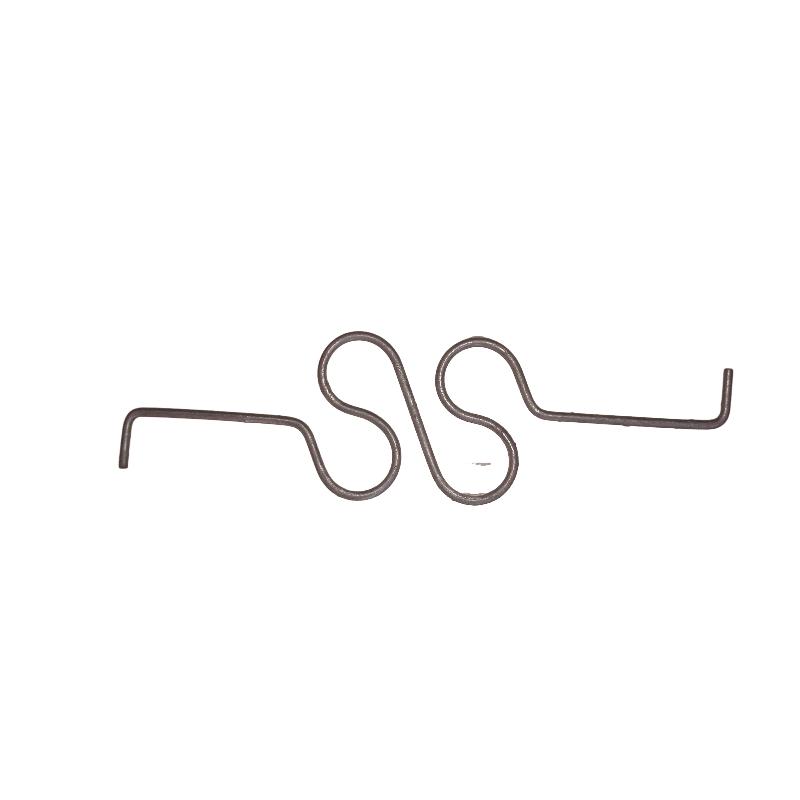

brick end ties. This is because they provide a cost-effective and reliable solution for joining bricks, while also adding an aesthetically pleasing touch to the final structure. The intricate patterns created by these ties can add depth and character to a building, making it truly unique.

brick end ties. This is because they provide a cost-effective and reliable solution for joining bricks, while also adding an aesthetically pleasing touch to the final structure. The intricate patterns created by these ties can add depth and character to a building, making it truly unique.Overall, heavy duty tension springs play a crucial role in a wide range of industries, providing the necessary force and reliability to keep mechanical systems operating smoothly and efficiently. Their strength and durability make them an essential component in many critical applications, ensuring that machinery and equipment can perform at their best.

But as they worked, the tree began to take on a new life, transforming into something magical before their eyes But as they worked, the tree began to take on a new life, transforming into something magical before their eyes

But as they worked, the tree began to take on a new life, transforming into something magical before their eyes But as they worked, the tree began to take on a new life, transforming into something magical before their eyes metal basket tree.

metal basket tree.

Extension Springs are important components in a variety of mechanical systems, providing the force needed to extend and retract parts. They come in a variety of sizes and types to suit different applications. From heavy-duty tension springs to micro extension springs, there are a variety of options to suit specific needs.