Relief valves come in several types, each suited for specific applications. The most common types include

Relief valves come in several types, each suited for specific applications. The most common types include

Safety is another paramount concern in the operation of natural gas distribution stations. The handling of flammable materials requires strict adherence to safety protocols and regulations. Distribution stations are equipped with advanced safety systems, including leak detection technology and emergency shut-off valves, designed to prevent accidents and ensure the safety of both personnel and the surrounding community. Regular safety inspections and maintenance are conducted to uphold high safety standards and mitigate risks associated with gas distribution.

2. Static Storage Tanks Used primarily in industrial settings, these larger tanks are designed for bulk storage of gases, such as propane or natural gas. They are often installed permanently and equipped with advanced safety features.

Understanding Electric Water Heaters Efficiency and Convenience

For instance, in the financial sector, regulators are increasingly using advanced algorithms to monitor transactions for signs of fraud or money laundering

. By analyzing vast amounts of transactional data, smart regulators can detect anomalies that may indicate illicit activities. This proactive stance not only enhances the effectiveness of regulatory oversight but also reduces the burden on businesses that comply with regulations, allowing them to focus on innovation and growth.

Applications of Gas Pressure Reducers

1. Convection Heaters These heaters operate on the principle of convection, where warm air rises and circulates throughout the room. Common types of convection heaters include baseboard heaters and wall-mounted units. They are known for providing consistent warmth and are often energy-efficient.

The Concept of “Al-Fasle” Bridging Divides and Creating Connections

In various engineering and industrial applications, controlling the flow of liquids and gases is paramount for efficiency, safety, and operational integrity. Among the crucial components that facilitate this control is the closing valve, a device designed to regulate or halt the flow within a piping system. This article delves into the significance, types, applications, and working principles of closing valves.

Air purifiers work through various technologies, such as HEPA (High-Efficiency Particulate Air) filters, activated carbon filters, and UV light filters. HEPA filters capture a staggering 99.97% of particles that are 0.3 microns in size or larger, including dust mites, pollen, and pet dander. Activated carbon filters absorb odors and harmful chemicals, while UV light purifies the air by destroying bacteria and viruses. By utilizing these technologies, air purifiers significantly reduce the number of pollutants in the air we breathe.

Considerations for Implementation

Conclusion

Types of Gas Pressure Regulators

In conclusion, the rise of smart organizers marks a significant shift in how we approach organization and productivity. By harnessing the power of technology, these tools offer a more intuitive, integrated, and user-friendly approach to managing tasks and schedules. As we continue to navigate an increasingly complex world, smart organizers may very well become essential companions in our quest for efficiency and balance. Embracing this technology can unlock new potential for individuals, enabling them to focus not just on getting things done but on achieving their goals with clarity and purpose.

The operation of a filter separator is usually broken down into several key stages. Initially, the mixture enters the separator's chamber, where it encounters a perforated or filter media that captures solid particulates. This media is crucial as it determines the effectiveness and efficiency of the filtration process.

In conclusion, the City Gate Station is more than just a transportation hub – it is a symbol of progress and connectivity. Through its sleek design, bustling energy, and role in fostering unity and community, the station has become an integral part of the city's identity. As the city continues to grow and evolve, the City Gate Station will remain a beacon of hope and a testament to the power of connection and communication.

A natural gas pressure reducer is a device used to control and reduce the pressure of natural gas as it moves from high-pressure systems to lower-pressure networks. These devices are vital in maintaining a consistent and safe gas pressure for various applications, ensuring that the gas can be used effectively without the risk of damage or hazards.

In simple terms, a heat exchanger is a device designed to transfer heat between two or more fluids. These fluids may be separated by a solid wall to prevent mixing or may be in direct contact with each other. The primary goal is to either heat or cool a fluid without altering its phase, which makes heat exchangers indispensable in a myriad of processes.

Conclusion

Chemical scrubbing is a more advanced technique that involves the reaction of gas streams with liquid solutions to neutralize or remove contaminants. Scrubbers can effectively remove acidic gases, such as sulfur dioxide (SO2) and nitrogen oxides (NOx), converting them into less harmful substances. This method is particularly important in power plants and chemical manufacturing facilities, where emissions can have severe environmental impacts.

On a personal level, Al-Muthabit encourages individuals to cultivate resilience and stability in their lives. In the face of adversity, having a strong sense of self and a clear understanding of one’s values can serve as a guiding light. This aspect of Al-Muthabit calls for introspection, where individuals assess their beliefs and experiences, affirming what truly matters to them. Such reflection fosters a sense of purpose and direction, enabling one to navigate life’s challenges with confidence and clarity.

Importance in Natural Gas Operations

Similarly, water purifiers have emerged as vital tools for ensuring access to clean, safe drinking water. While tap water in many developed countries is treated to remove harmful bacteria and chemicals, it can still carry traces of heavy metals, chlorine, and other impurities. Water purifiers employ methods like reverse osmosis, UV purification, and activated carbon filtration to deliver fresher, cleaner water. With health concerns increasingly at the forefront of public awareness, the demand for efficient water purification systems has surged. By eliminating contaminants, water purifiers not only protect us from potential health risks but also enhance the taste and quality of our drinking water.

At its core, a coalescing filter is designed to remove water and solid particulates from fuels, oils, and other liquid applications. This is primarily achieved through a process referred to as coalescence, where small drops of liquid (typically water) cluster together to form larger droplets. These larger droplets can then be easily separated from the main fluid due to their increased size, thus enhancing the overall quality of the processed fluid.

To maximize the benefits of natural gas and address its challenges, a holistic approach is necessary. This includes investing in research and development to improve extraction and distribution technologies, implementing stringent regulations to limit methane emissions, and promoting transparent communication with the public about the role of natural gas in a sustainable energy future.

Gas Pressure Reduction Valve An Essential Component in Gas Systems

4. Air Conditioning and Ventilation In HVAC systems, gas heat exchangers are instrumental in recovering energy from exhaust air, thus enhancing the efficiency of heating and cooling systems and promoting sustainability.

In water supply systems, pressure reducing valves help maintain a consistent water pressure, safeguarding plumbing systems from potential damage caused by high-pressure surges. In industrial settings, these devices are vital for processes involving gases and liquids that require precise pressure controls to ensure optimal performance and safety.

In summary, pressure reducing valves are indispensable in today's fluid management systems. By ensuring the right pressure levels, they help maintain operational safety, improve efficiency, and extend the lifespan of equipment. Understanding the function, types, and applications of PRVs can aid in selecting the appropriate valve for specific needs, ultimately contributing to smoother and safer operations in various industries. As technology advances, the design and functionality of pressure reducing valves will continue to evolve, further enhancing their importance in fluid management systems worldwide.

Gas pressure reduction valves are essential in ensuring that the delivery pressure of gas to end-users is within safe and manageable limits. High-pressure gas that flows through pipelines can pose significant risks, including leaks, explosions, and damage to appliances. By regulating the pressure, GPRVs help to maintain a safe operating environment.

As industries strive for greater energy efficiency and sustainability, the role of heat exchangers becomes ever more crucial. Innovative designs, materials, and technologies continue to emerge, enhancing their performance and efficiency. The integration of heat recovery systems and advanced control strategies further increases their effectiveness, contributing to greener industrial practices.

2. Aerospace and Automotive The aerospace and automotive industries are always in pursuit of materials that can enhance performance and fuel efficiency. 1% fiberglass tubes can be employed in components that require a balance of weight and sturdiness. For example, they may be used in the framework of vehicles or as part of aircraft interiors, where strong yet lightweight materials contribute to overall efficiency.

Single coil razor barbed wire stands as an effective solution for security and containment, with wide-ranging applications across multiple sectors. Its design not only enhances security but also provides a practical solution to modern challenges in safety and protection. As communities and industries continue to evolve, so too will the methods we employ to safeguard our spaces, making innovations like single coil razor barbed wire invaluable in our pursuit of safety and security. Whether in agriculture, urban settings, or high-security facilities, the utility of this unique fencing solution cannot be overstated.

Because sulphuric acid is a strong acid, a sulphuric acid solution of 0.50 M has a pH near zero.

Electro galvanized barbed wire is created by coating steel wire with a layer of zinc through an electroplating process. This procedure enhances the wire's resistance to rust and other atmospheric elements. The unique design of barbed wire, featuring sharp points or barbs spaced along its length, makes it an effective deterrent against unauthorized access, thereby providing an added level of security.

Fiberglass rods are composite materials made from a mixture of glass fibers and resin. This composite structure provides excellent strength-to-weight ratio, corrosion resistance, and flexibility. Fiberglass rods can come in various percentages of fiberglass concentration, and a 1.25% fiberglass rod denotes that the rod contains 1.25% fiberglass content relative to the total composite material. This lower concentration makes these rods particularly lightweight while still retaining essential strength characteristics.

The 3% 204-inch fiberglass rod exemplifies how advanced material science can produce highly versatile and durable products. With their unique mixture of strength, lightweight nature, corrosion resistance, and electrical insulation, these rods open the door to a multitude of applications across various sectors. Whether in construction, sports, or agriculture, the use of fiberglass rods like these enhances operational efficiency while ensuring safety and durability. As industries continue to innovate, the demand for and reliance on such specialized materials will undoubtedly grow, further solidifying fiberglass rods as a staple in modern applications.

Moreover, galvanized wire is cost-effective, offering an excellent balance between performance and price. This affordability has contributed to its widespread adoption across various industries in China.

5. Removal and Finishing After curing, the FRP pipe is removed from the mandrel, and finishing processes such as trimming or polishing may be applied to achieve the final specifications.

This feature is particularly crucial in regions with fluctuating weather conditions or heavy rainfall, ensuring the integrity of the roofing system remains intact This feature is particularly crucial in regions with fluctuating weather conditions or heavy rainfall, ensuring the integrity of the roofing system remains intact

This feature is particularly crucial in regions with fluctuating weather conditions or heavy rainfall, ensuring the integrity of the roofing system remains intact This feature is particularly crucial in regions with fluctuating weather conditions or heavy rainfall, ensuring the integrity of the roofing system remains intact bwg9x2.5 rubber washer roofing nails.

bwg9x2.5 rubber washer roofing nails.The versatility of pultruded fiberglass tubes allows them to be employed in numerous sectors. One of the significant applications is in the construction industry, where they are used for structural support, roofing systems, and scaffolding. Their lightweight nature reduces transportation costs and simplifies installation.

The versatility of pultruded fiberglass tubes allows them to be employed in numerous sectors. One of the significant applications is in the construction industry, where they are used for structural support, roofing systems, and scaffolding. Their lightweight nature reduces transportation costs and simplifies installation.

3. Transportation In the automotive and aerospace sectors, fiberglass square tubes are utilized in manufacturing frames and supports. Their lightweight properties significantly contribute to fuel efficiency, and their strength ensures safety.

China has emerged as a global leader in the production of black steel nails, thanks to its advanced manufacturing techniques and vast availability of raw materials. The production process involves drawing out steel wire and shaping it into nails, which are then heat-treated to enhance their strength and durability. This efficient manufacturing process allows for the mass production of high-quality nails at competitive prices.

Moreover, U-type nails are revered for their versatility. They are often used in applications ranging from fastening wiring and insulation to building frames for furniture. Their design allows for a secure hold, making them indispensable in ensuring the longevity and robustness of the projects they are part of.

In conclusion, China electro galvanized barbed wire is a dependable and efficient fencing material that offers enhanced security, durability, and cost-effectiveness. With its electro galvanized surface treatment, high tensile strength, versatility, and affordability, this type of barbed wire is a top choice for various applications in China, ranging from residential to commercial to agricultural settings. Whether you need to secure a perimeter, protect a property, or deter intruders, electro galvanized barbed wire is an excellent option that provides peace of mind and ensures the safety of your assets.

One of the primary benefits of using a fiberglass septic tank is its material. Fiberglass is inherently resistant to corrosion and degradation, which is a significant concern for traditional concrete or metal tanks. This durability ensures that fiberglass tanks can withstand various environmental conditions without cracking, rusting, or leaking, thus providing a longer lifespan.

In today's construction and manufacturing industries, color plays a crucial role in not only aesthetics but also functionality. Among the wide array of color choices available, red has emerged as a popular selection, particularly in the use of red color steel coils. These coils are not just standard steel products; they embody a combination of practicality, visual impact, and a broad spectrum of applications.

Copper boat nails are an essential component in the construction and maintenance of boats. These nails are made of high-quality copper, which is known for its durability, strength, and resistance to corrosion. The use of copper boat nails ensures that the boat remains sturdy and secure, even in harsh marine environments.

Understanding Galvanized Wire Cloth Pricing A Comprehensive Overview

Applications and Usage

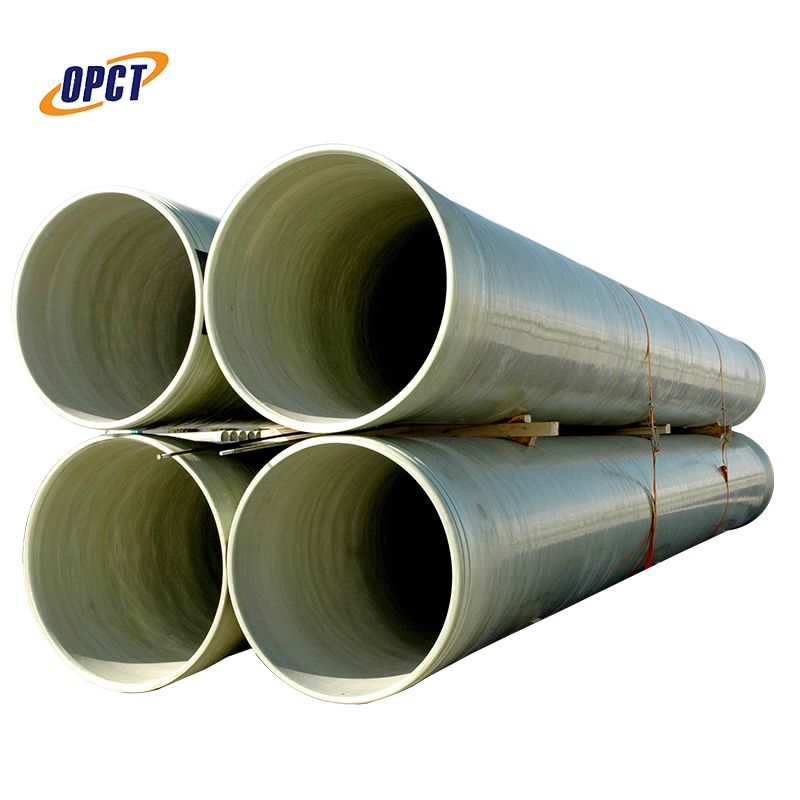

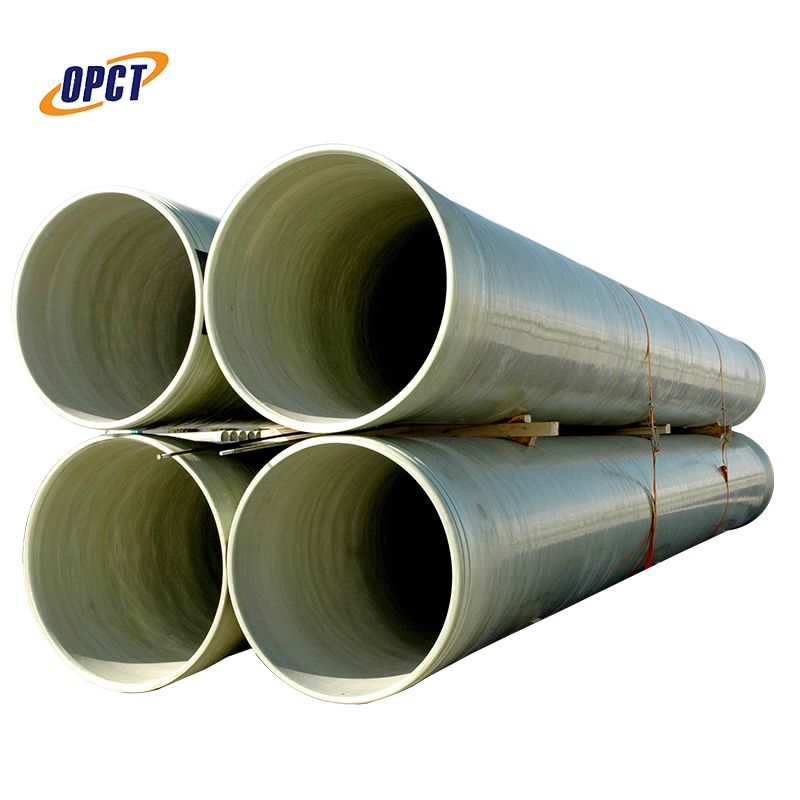

- Corrosion Resistance One of the most significant benefits of FRP pipes is their resistance to corrosion. This property makes them ideal for applications in harsh environments, such as chemical processing plants, where traditional materials may degrade over time.

In the construction and manufacturing industries, plastic coated iron wire is commonly used for reinforcing concrete, securing structures, and installation of safety nets. Its durability makes it the preferred choice for site management, providing security without the sharp edges that bare iron can present. The colorful plastic coating also allows for the creation of visually appealing designs, which can enhance the aesthetic quality of commercial and residential buildings.

U-type nails, characterized by their unique shape and design, are essential components in various construction and crafting projects. These nails are widely utilized in the assembly of wooden structures, furniture, and even in bespoke crafts. This article delves into the workings of U-type nail factories, focusing on their production processes, machinery, quality control, and the significance of this product in the market.

The head is formed at one end, while the other end is cut and shaped into a sharp point The head is formed at one end, while the other end is cut and shaped into a sharp point

The head is formed at one end, while the other end is cut and shaped into a sharp point The head is formed at one end, while the other end is cut and shaped into a sharp point iron wire for making nails. The result is a robust, precision-made nail ready for use.

iron wire for making nails. The result is a robust, precision-made nail ready for use.As online shopping continues to grow in popularity, the need for reliable and user-friendly price comparison websites like Pricewire will only increase. By providing consumers with the tools and information they need to make smart purchasing decisions, Pricewire is helping to make the world of online shopping more transparent and consumer-friendly.

Another benefit is its versatility; the mesh can be easily cut, shaped, and assembled to meet various project requirements. Whether in a construction site or an agricultural setting, 18-gauge wire mesh can adapt to the specific needs of the application.

Pure iron nails are made from high-purity iron, typically containing over 99% iron with minimal impurities. This composition lends them unique characteristics, such as excellent corrosion resistance and malleability. Unlike steel nails, which may include alloying elements like carbon, pure iron nails offer a softer material that can be easily manipulated during the manufacturing process. Their structure allows for exceptional ductility and flexibility, making them ideal for various applications.

5. Transportation and Installation While FRP pipes are generally lighter than traditional materials like steel or concrete, transportation costs can still add up. Furthermore, installation costs can vary based on the complexity of the project. Specialized fittings and joints may be required, impacting overall expenses.

Installation and maintenance should also be factored into the total cost. While stainless steel tanks require less frequent maintenance compared to alternative materials, they still need to be installed correctly to ensure optimal performance. Hiring a professional for installation can lead to additional costs, but it is crucial for the tank's durability and proper functioning.

The cost of a 500-gallon fiberglass septic tank can vary based on various factors, including location, installation complexity, and local regulations. On average, fiberglass tanks may initially be more costly than concrete tanks; however, their longevity and reduced maintenance requirements often make them a more economical choice over time.

Uses of Birdcage Chicken Wire Mesh