There are several types of regulating valves, each suited for different applications. The most common types include

There are several types of regulating valves, each suited for different applications. The most common types include

Challenges and Considerations

How Pressure Regulating Valves Work

Natural Gas Distribution Stations The Backbone of Energy Infrastructure

- Regulatory Compliance Many industries are subject to strict regulations governing the safe handling of gas. Installing appropriate safety valves is often a legal requirement, helping businesses comply with safety standards set by organizations like OSHA and the EPA.

On a global scale, the recognition of fasil structures, like Fasil Ghebbi, highlights the importance of preserving cultural monuments that tell the story of humanity’s shared past. These sites become focal points for tourism, education, and intercultural dialogue, fostering a greater understanding of the diverse narratives that shape our world. They remind us that architecture is not merely about materials and design; it's about the stories entwined within the walls and the lives that have unfolded across generations.

Research into nanotechnology and advanced materials is paving the way for more efficient gas filters, capable of capturing a wider range of contaminants. Additionally, the integration of smart monitoring systems can help industries optimize filter performance, providing real-time data on air quality and filter status.

City Gate Station A Nexus of Urban Connectivity

Benefits of Using Pressure Regulating Devices

Gas pressure vessels, often referred to as gas cylinders or gas tanks, are essential components in various industries, providing a safe and efficient means to store and transport gases. These vessels are designed to handle high-pressure environments, ensuring that gases can be stored safely for commercial, industrial, and even medical purposes.

What is a Natural Gas Filter Separator?

In addition to safety, gas regulators contribute to operational efficiency. By maintaining a constant and appropriate pressure level, they prevent fluctuations that could lead to inconsistent performance of burners, heaters, and other gas-powered equipment. This consistency allows for optimized combustion processes, resulting in better fuel efficiency and reduced emissions. Industries can thus achieve their environmental targets while saving on energy costs, making gas regulators a smart investment.

Relief valves play an indispensable role in numerous industries, including oil and gas, chemical manufacturing, and water treatment. In the oil and gas sector, for instance, relief valves are essential in pipeline systems where pressure must be monitored closely to prevent leaks or bursts. In chemical manufacturing, where volatile substances are handled, these valves help mitigate risks associated with pressure fluctuations that could lead to explosive reactions.

Natural gas is a crucial energy source used in residential, commercial, and industrial applications around the world. However, its safe and efficient use relies heavily on maintaining appropriate pressure levels throughout the distribution system. This is where natural gas pressure regulators come into play. These devices ensure that gas is delivered at consistent and safe pressures, preventing potential hazards while optimizing energy delivery to end-users.

Natural gas has emerged as one of the primary energy sources used across the globe, favored for its clean combustion properties and lower carbon emissions compared to other fossil fuels. However, the natural gas extracted from reservoirs is often contaminated with impurities, including water, hydrogen sulfide, carbon dioxide, and particulate matter. Filtration plays a crucial role in ensuring that natural gas meets the necessary quality standards before it reaches consumers and industrial users. This article explores the significance of natural gas filtration, the filtration methods used, and the technological advancements shaping this field.

The role of closing valves in fluid control systems is integral to the functionality, safety, and efficiency of various industries. By selecting the appropriate type of closing valve for specific applications, engineers and operators can ensure optimal performance and reliability in fluid management. As technologies advance, the design and materials used in closing valves continue to evolve, promising even greater efficiency and safety in fluid control systems. The closing valve may seem like a simple component, but its impact on industrial processes is profound and far-reaching.

The use of gas heat exchangers brings numerous benefits

The primary function of a gas heat exchanger is based on the principles of thermodynamics. Heat naturally flows from a higher temperature body to a lower temperature body. In a gas heat exchanger, this principle is exploited to transfer heat from a hot gas to a cooler gas, thereby raising the temperature of the incoming gas.

Benefits of Electric Auxiliary Heaters

When the gas pressure is too high, the diaphragm pushes against the spring, causing the valve to close slightly, reducing the flow of gas. Conversely, if the pressure drops below a certain threshold, the diaphragm allows the valve to open wider, permitting more gas to flow through. This continuous adjustment process ensures that the output pressure remains steady, regardless of fluctuations in supply pressure.

In the woodworking industry, cyclones play a crucial role in sawdust extraction, preventing the buildup of flammable materials and reducing the risk of fire hazards. Furthermore, in power generation, they are employed in power plants to prevent ash and other particulates from entering flue gas systems.

The functionality of pneumatic valves can be summarized in several key roles

Applications and Importance

Types of Natural Gas Regulators

Importance of Gas Metering

How Gas Pressure Reducers Work

A natural gas regulator is a mechanical device designed to control the pressure of natural gas as it flows from the supply source to the end user. The primary function of the regulator is to reduce the high pressure of gas from pipelines or storage tanks to a lower, manageable pressure that can be safely used in residential, commercial, or industrial applications. This regulation is vital because different appliances, such as heaters, stoves, and generators, are designed to operate at specific pressure levels. If gas is delivered at an incorrect pressure, it could lead to inefficient operation, potential damage to appliances, or even hazardous safety issues, including gas leaks or explosions.

The Purpose of Pressure Reduction Stations

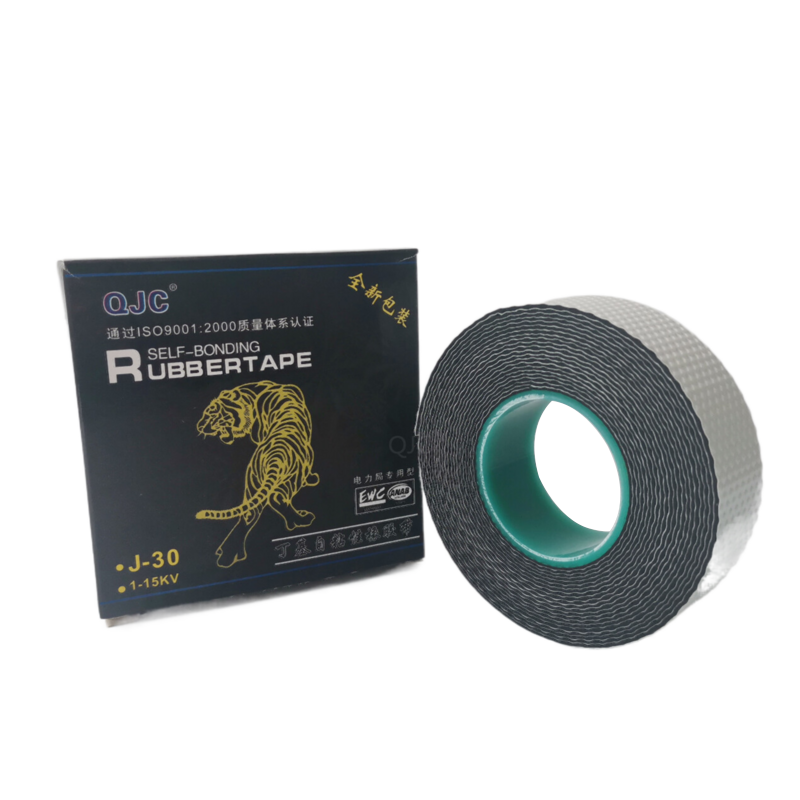

If you have any more questions about our silicone tapes, or any other tape products, please get in touch and contact us via live chat, email or telephone.

Installing heat tape requires some planning and careful execution. Before installation, it is essential to ensure the surface is clean and dry. The tape needs to be secured properly to prevent slipping or improper heating distribution. Additionally, all electrical components should be installed according to local building codes to ensure safety and compliance.

Sometimes, cars cause problems at the least opportune times, so keeping a roll of butyl tape in your car for those unexpected issues can come in handy. You can use butyl tape for quick emergency car repairs like filling gaps on a firewall or fixing a sunroof.

The Versatility of Black Flex Tape A Game-Changer in Home Repair

Overall, PVC marking tape is an essential tool for efficient and effective workplace organization. It helps streamline operations, improve safety, and reduce the risk of errors or accidents. With its versatility, durability, and ease of use, PVC marking tape is a valuable asset for any industry or workplace.

To use the tape, simply stretch it around the material you are trying to repair. As you wrap the tape in a circular motion, it begins to seal and “fuse” itself to the material. The most common forms of self-fusing / self-amalgamating tapes are made of silicone rubber (though other types also exist). They are designed to create a strong, seamless, rubbery, waterproof, and electrically insulating layer.

The main issue with buying tape online is that there are literally dozens of different types of adhesive tape on the market. Within each of these types, you can select from different options such as color, width, and thickness. The high degree of variation allows clients to select tapes that are perfectly tailored to their needs. However, some consumers can feel overwhelmed when reviewing their choices. Additionally, when you buy tape online, you have no way of knowing exactly how well the tape will work until your order arrives. Imagine buying a custom packing tape only to discover when it arrives that the width isn't compatible with your box sizes!

PVC Electrical Insulation A Versatile Solution for Many Applications

It serves as a silent reminder to maintain personal space, contributing to public health and safety It serves as a silent reminder to maintain personal space, contributing to public health and safety

It serves as a silent reminder to maintain personal space, contributing to public health and safety It serves as a silent reminder to maintain personal space, contributing to public health and safety yellow line marking tape.

yellow line marking tape.Self-fusing tape is a versatile and useful product that has a wide range of applications. Self-fusing tape is a type of tape that fuses to itself when applied, creating a strong and durable bond. This type of tape is typically made from silicone, which gives it unique properties that make it ideal for a variety of uses.

Another benefit of PVC marking tape is its ease of use. It is typically self-adhesive, allowing for quick and hassle-free application. Workers can simply peel off the backing and stick the tape onto the desired surface, whether it be pipes, walls, floors, or machinery. This saves time and effort compared to other marking methods, such as paint or markers.

Its resistance to abrasion, chemicals, and temperature fluctuations makes it suitable for use in both indoor and outdoor environments Its resistance to abrasion, chemicals, and temperature fluctuations makes it suitable for use in both indoor and outdoor environments

Its resistance to abrasion, chemicals, and temperature fluctuations makes it suitable for use in both indoor and outdoor environments Its resistance to abrasion, chemicals, and temperature fluctuations makes it suitable for use in both indoor and outdoor environments pvc insulation electrical tape.

pvc insulation electrical tape.