How a Gas Pressure Reducer Works

How a Gas Pressure Reducer Works

Applications of Pressure Relief Valves

2. Two-stage Regulators More complex than their single-stage counterparts, two-stage regulators provide a more stable output pressure by employing two distinct pressure-reducing mechanisms. This makes them suitable for applications that require precise pressure control, including laboratory settings and industrial processes.

4. Non-Return Valves While not traditional relief valves, these devices prevent backflow in systems and can assist in controlling pressure levels by ensuring that fluids only flow in one direction.

To ensure the longevity and efficiency of gas pressure regulators, regular maintenance is critical. This includes checking for leaks, replacing worn-out components, and verifying that the regulator is functioning as intended. Neglecting maintenance can lead to performance issues, increased energy costs, and safety hazards.

Moreover, the use of decompression skids enhances operational efficiency. By ensuring that the decompression process occurs in a controlled environment, operators can minimize downtime and optimize resource extraction. This is particularly important in offshore platforms, where limited access to repair and maintenance can lead to significant production losses if equipment fails.

In addition to protecting industrial equipment, basket strainers also play a crucial role in ensuring the quality and safety of the final products. For example, in the food and beverage industry, strainers are used to remove impurities and contaminants from the production process, ensuring that the final products meet the required standards for consumption. Similarly, in water treatment plants, strainers help to remove sediment and pollutants from the water, making it safe for drinking and other uses.

Testing and Maintenance

A natural gas safety valve is a critical component in gas distribution systems. It is designed to regulate the flow of gas and prevent excessive pressure build-up within pipelines, appliances, and storage systems. These valves are engineered to automatically close under specific conditions, thereby preventing potential hazards like explosions or leaks. Safety valves come in various types, including relief valves, shut-off valves, and pressure-regulating valves, each serving a unique purpose in managing gas safely.

- Energy Efficiency Electric heaters, especially tankless models, typically consume less energy compared to gas models, particularly in areas where electricity is generated from renewable sources.

While pressure reducing valves are generally reliable, regular maintenance is crucial to ensure they function correctly. Periodic inspections should be conducted to check for leaks, corrosion, and wear. A malfunctioning PRV can lead to either over-pressurization or inadequate pressure, both of which can have detrimental effects on a system.

Types of Gas Pressure Regulators

The Precision Voltage Regulator An Essential Component in Modern Electronics

In the realm of engineering and applied sciences, filters play a crucial role in a variety of processes, from water purification to electronic signal processing. One fascinating type of filter that has gained attention in recent years is the coalescing filter. This article delves into the functionality and applications of coalescing filters, elucidating their importance in various industries.

Advancements in Technology

One of the most common types of gas filters is the activated carbon filter. Activated carbon, due to its high surface area and porous nature, is highly effective at adsorption—the process by which gases adhere to the surface of a solid. This type of filter is particularly effective for volatile organic compounds (VOCs), odors, and certain heavy metals. It is widely used in air purification systems, HVAC systems, and for removing contaminants in workplace environments.

In recent years, the rise of technology and digital platforms has introduced new challenges for regulators. The rapid growth of companies like Amazon, Google, and Facebook has prompted regulatory bodies to reassess their frameworks to address issues related to data privacy, market power, and consumer rights. Regulators are now tasked with tracking and managing the complexities of the digital economy, ensuring that innovation does not come at the expense of consumer protection or fair competition. This evolution highlights the need for regulators to be adaptable and proactive in their approaches.

Maintenance and Safety Considerations

While the benefits of using sliders are clear, there are several factors to consider when implementing this system. Firstly, the weight and size of the equipment must be evaluated to ensure that the slider can support the load without compromising safety or performance. Furthermore, maintaining a well-balanced configuration is essential to prevent tipping or instability during movement.

The art installations adorning the walls, showcasing the works of local artists, add a dash of color and creativity to the space, reflecting the city's thriving arts scene The art installations adorning the walls, showcasing the works of local artists, add a dash of color and creativity to the space, reflecting the city's thriving arts scene

The art installations adorning the walls, showcasing the works of local artists, add a dash of color and creativity to the space, reflecting the city's thriving arts scene The art installations adorning the walls, showcasing the works of local artists, add a dash of color and creativity to the space, reflecting the city's thriving arts scene city gate station.

city gate station.However, it is essential to select the appropriate pneumatic control valve for specific applications. Factors such as pressure ranges, flow capacity, and response times should be carefully considered to ensure optimal performance. Furthermore, regular maintenance and monitoring are crucial to prevent any potential operational issues and ensure the longevity of the pneumatic systems.

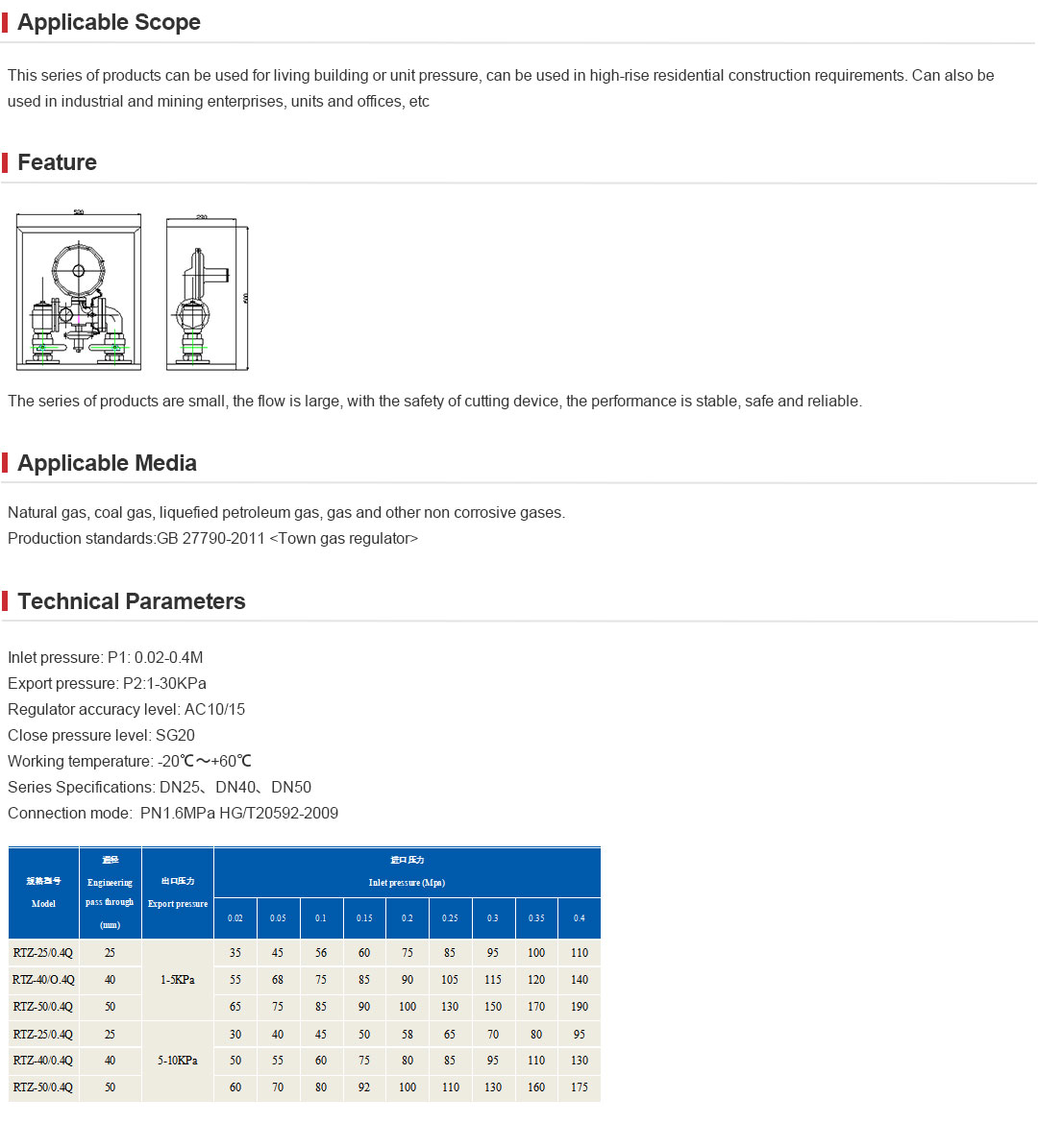

The function of a PRS is to decrease this high pressure to suitable levels while maintaining the required flow rate, temperature, and quality of the gas. PRS installations can vary in complexity, from simple setups used in rural areas to sophisticated systems employed in urban centers.

Safety is another paramount concern in the operation of natural gas distribution stations. The handling of flammable materials requires strict adherence to safety protocols and regulations. Distribution stations are equipped with advanced safety systems, including leak detection technology and emergency shut-off valves, designed to prevent accidents and ensure the safety of both personnel and the surrounding community. Regular safety inspections and maintenance are conducted to uphold high safety standards and mitigate risks associated with gas distribution.

The choice of material for pressure pipes is vital as it affects durability, cost, and application suitability

. Common materials includeGas pressure regulating valves can be classified into various types depending on their design and application

.The Importance of Safety Valves in Industrial Applications