Understanding Electric Regulating Valves Functionality, Benefits, and Applications

Understanding Electric Regulating Valves Functionality, Benefits, and Applications

In conclusion, safety valves are a fundamental component of many industrial systems, offering essential pressure relief to prevent dangerous situations. Their reliability, durability, and proper maintenance are paramount for ensuring both personnel safety and equipment integrity. As industries continue to evolve and technology advances, the design and function of safety valves will also adapt, maintaining their critical role in safeguarding industrial operations. Investing in high-quality safety valves and adhering to rigorous testing and maintenance protocols is not just a regulatory obligation; it is a commitment to safety and excellence in industrial practice.

Understanding the Coalescing Filter Functionality and Applications

Safety First

Al-fasl can be understood in both a literal and metaphorical sense. Literally, it refers to physical separation, such as dividing different segments of a land, creating boundaries, or differentiating between distinct categories. Metaphorically, al-fasl extends to various domains, including literature, education, and law—each reflecting the necessity to delineate ideas, concepts, and regulations.

In addition to safety and maintenance, regulatory compliance plays a significant role in the design and implementation of PRVs. Various national and international standards govern the specifications and testing of pressure relief valves, ensuring they meet the safety requirements of specific industries. Manufacturers must navigate these regulations carefully, as non-compliance can lead to legal ramifications and severe impacts on the company’s reputation.

Safety valves play a crucial role in ensuring the safe and efficient operation of various industrial systems. These devices are designed to prevent excessive pressure build-up by providing a reliable means of pressure relief, thereby protecting equipment and personnel from potential hazards. In industries such as oil and gas, chemical manufacturing, and power generation, safety valves are indispensable components that contribute to overall system safety.

There are several types of heat exchangers used in natural gas applications, each tailored for specific functions

Advantages of Using Natural Gas Filter Separators

Moreover, advanced gasifiers can capture pollutants such as sulfur oxides and nitrogen oxides, thus reducing the emission of harmful substances into the atmosphere. The technology is continually evolving, with innovations aimed at improving efficiency and reducing costs associated with gasification systems.

In the realm of economics, the term basket refining pertains to the method of assessing and analyzing a collection of assets or commodities to derive a comprehensive understanding of value and performance. This concept is particularly relevant in the context of investment portfolios, indices, and price measurements. The basket typically refers to a grouping of related items—be it stocks, commodities, or other financial instruments—while refining suggests the process of fine-tuning these categories to yield more accurate insights.

Moreover, the quality of natural gas directly influences the performance of end-use applications, such as power generation, heating, and industrial processes. Clean gas has higher calorific value, leading to better energy output and reduced emissions. As such, the natural gas industry is increasingly prioritizing filtration strategies to maintain gas quality and meet the demands of a sustainable energy future.

What is a Pressure Regulator?

Understanding Flutter The Future of Cross-Platform App Development

In addition, modern advancements in valve technology, including automation and smart monitoring systems, allow for real-time adjustments to gas flow. This level of control is crucial for adapting to fluctuating demand and maintaining stable supply, particularly as the energy landscape changes and renewable energy sources become more prevalent.

Natural gas regulators operate based on a mechanical design that reacts to changes in gas pressure. The key components of a typical gas regulator include a valve, a diaphragm, and a spring. The diaphragm moves in response to pressure changes, which allows the regulator to increase or decrease the flow of gas based on demand or supply fluctuations.

Pressure reduction stations, often referred to as PRS, are strategically located along gas pipelines. Their primary function is to reduce the high pressure of natural gas—often exceeding 1,000 psi—down to safer levels, typically around 10 to 60 psi, that are suitable for household usage. This pressure reduction is achieved through a combination of mechanical and equipment methodologies, including pressure regulators, control valves, and safety devices.

3. Enhanced Safety Maintaining optimal gas pressure through boosting minimizes the risks associated with pressure drops, such as leaks or ruptures in pipelines. A stable pressure ensures a safer transport method.

3. Reduction In the final stage, the char reacts with limited oxygen and steam, producing syngas. The composition of syngas typically includes hydrogen, carbon monoxide, and small quantities of methane, and can be refined and utilized as a clean fuel source.

Understanding Gas Metering An Essential Component of Energy Management

Pressure control systems play a critical role in various industrial applications, ensuring the safe and efficient operation of equipment and processes. These systems help maintain desired pressure levels within a specified range, preventing adverse conditions that could lead to equipment failure, safety hazards, and decreased productivity. In industries such as oil and gas, chemical manufacturing, and food processing, proper pressure management is essential for optimal performance and compliance with safety regulations.

Challenges and Innovations

Understanding Electric Water Heaters

Regulating valves, often referred to as control valves, are designed to adjust the flow rate of a fluid based on the feedback from a control signal. The controlling element of the valve responds to changes in system pressure, temperature, or flow rate, allowing for precise flow management. These valves can be modulated using various mechanisms, including pneumatic, electric, or hydraulic actuators, providing flexibility in operation and integration into automated systems.

In addition to performance, safety is a paramount concern. Gas leaks can lead to explosions and environmental hazards. Properly functioning regulators prevent over-pressurization, which is crucial for preventing accidents.

- Direct-Acting Pressure Reducing Valves These are the most common types and work by using a spring mechanism that responds directly to changes in pressure. They provide quick reactions to pressure fluctuations.

In conclusion, measurement systems form the backbone of quantifying the world around us. Their importance spans across various domains, facilitating standardization, comparison, and innovation. By understanding and utilizing these systems effectively, we can improve our communication and enhance the quality of our work and daily activities. Whether in a scientific lab, at a manufacturing facility, or in our kitchens, measurement systems remain integral to our understanding and interaction with the world.

In today's rapidly evolving digital landscape, the need for efficient data processing is paramount. As massive volumes of data are generated every second, techniques to filter and manage this data effectively have become essential. Among these techniques, coalescing filters play a significant role in optimizing data handling, especially in applications involving stream processing and real-time analytics.

The industry is witnessing a range of innovations aimed at improving the design and functionality of filter separators. Advancements in material science may lead to more durable filter media that can withstand harsher conditions and extend the time between maintenance cycles. Additionally, the integration of smart technologies like IoT sensors can allow for real-time monitoring and predictive maintenance, thereby enhancing reliability and efficiency.

2. Two-Stage Regulators These regulators provide more accurate pressure control by employing two distinct pressure-reducing mechanisms. The first stage drops the pressure to an intermediate level, while the second stage provides fine control, making them ideal for applications requiring precise pressure regulation.

Chain Stitch Sewing An Overview of Technique and Applications

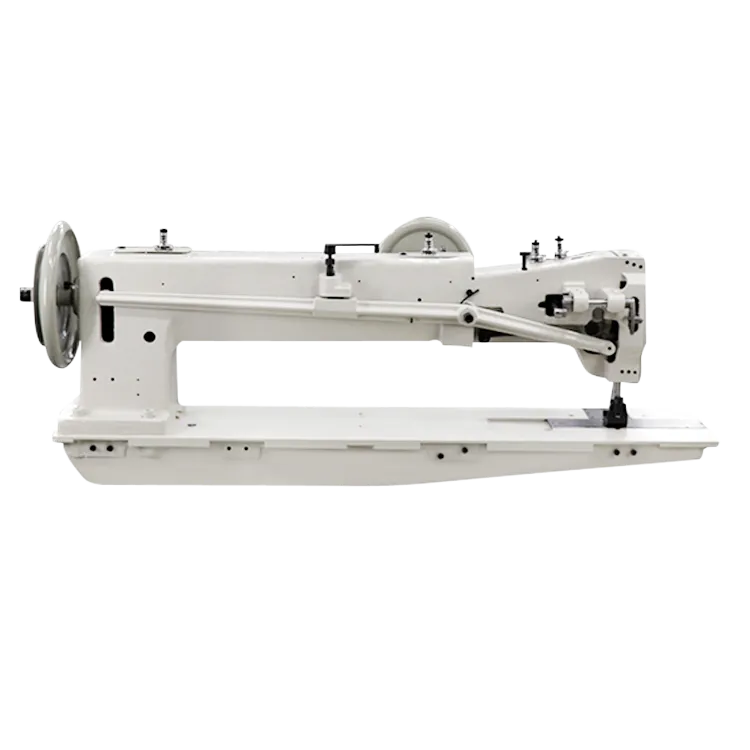

In the world of sewing, having the right tools can make all the difference between a creative project and a frustrating experience. One tool that has gained recognition among both enthusiasts and professionals is the heavy duty pattern sewing machine. Known for its durability, versatility, and powerful performance, this machine is a game changer for anyone who loves to sew.

3. Speed and Efficiency These machines are designed for high-speed operation, significantly reducing production time and costs in large-scale manufacturing environments.

What to Consider When Purchasing

Factors Influencing the Price

5. Warranty and Customer Support Machines that come with a longer warranty and better customer support tend to be priced higher. A good warranty can provide peace of mind, especially for those investing in more expensive machinery.

Sewing Machine for Car Seats Cover A Comprehensive Guide

The Advancements in Cylinder Arm Sewing Machines for Leatherworking

Sewing with a Twin Needle

There are several types of PP woven bag stitching machines available, each designed to cater to specific production needs. Some of the most common types include

- Apparel Production The lock stitch is prevalent in finishing seams, hems, and securing fabric layers, providing a clean and professional look to garments.

In recent years, there has been a growing focus on sustainability within the packaging industry. PP bags are recyclable, which aligns with environmental initiatives aimed at reducing plastic waste. As a result, the integration of PP bag stitching machines into production lines also contributes to eco-friendly practices by facilitating the use of recyclable materials.

When looking for a single needle quilting machine, it's important to consider your budget and what features are most important to you. Prices for these machines can range from a few hundred dollars to several thousand dollars. The more expensive machines typically offer more advanced features, such as larger quilting spaces, higher stitching speeds, and more built-in quilt designs.

5. Adjustable Stitch Length Different styles and techniques require various stitch lengths. A sewing machine that allows for easy adjustments will enable the maker to achieve the desired look and durability in seams.

In the world of garment manufacturing and textile production, efficiency and precision are paramount. One type of sewing machine that has become increasingly popular among professionals is the cylinder bed sewing machine. For those seeking to enhance their sewing operations, there are numerous cylinder bed sewing machines for sale, each offering unique advantages that cater to specific sewing needs.

Enhanced Efficiency

2. Versatility This stitch can be used on various fabrics, from delicate materials to heavy-duty textiles.

In summary, the high-speed single needle lockstitch sewing machine stands as a cornerstone of modern garment production. Its design, speed, versatility, and efficiency make it an essential tool for manufacturers seeking to optimize their operations. As the textile industry continues to evolve, these machines will undoubtedly remain vital in driving innovation and meeting the ever-growing demands for quality and efficiency in garment manufacturing. Whether in a large factory or a small atelier, the high-speed single needle lockstitch sewing machine is a testament to the blend of tradition and technology in the art of sewing.

Advantages of Single Stitch Leather Sewing Machines

Automatic bag closer machines are designed to seal bags rapidly and securely, using a variety of methods including heat sealing, stitching, and adhesive sealing. The selection of a sealing method often depends on the type of product being packaged, the material of the bag, and the desired durability of the seal. For instance, in industries dealing with perishable goods such as food and pharmaceuticals, heat sealing is often preferred for its ability to create airtight seals that prolong shelf life.

Furthermore, it features an automatic needle threader, which simplifies preparation and minimizes frustration. The included walking foot also aids in evenly feeding layers of leather, allowing for consistent stitch alignment. This focus on ease of use ensures that leatherworkers can concentrate on their creativity rather than getting bogged down by technical difficulties.

Heavy-Duty Sewing Machines: These machines are made for home workers who sometimes need to work with tougher fabrics like leather or denim. Even though they can handle more complex jobs than a regular home machine, they are not made for high-volume, continuous sewing.

Case Studies Comparing Costs Over Time

Conclusion

2. Upholstery Projects

Embroidery has always been a cherished art form, embodying creativity and craft. With technological advancements, traditional embroidery techniques have evolved, giving rise to sophisticated machinery designed to streamline and enhance the embroidery process. Among these innovations, the zigzag embroidery machine has emerged as a popular choice for both hobbyists and professional embroiderers.

When you finish your sewing project, carefully cut the threads and remove any excess fabric. Inspect your work to ensure the twin needle has given you the desired effect of two parallel lines. Iron the seams to give them a crisp finish and enhance the professional appearance of your project.

In conclusion, GSC367TD represents a significant advancement in technology with its powerful data processing, user-friendly design, robust security features, and focus on sustainability. As organizations continue to seek innovative solutions to enhance efficiency and drive growth, GSC367TD emerges as a reliable partner. By investing in this technology, businesses position themselves to thrive in an ever-evolving landscape, ensuring they remain competitive and responsive to changing demands.

To achieve the best results in heavy-duty sewing, several techniques can be employed

Understanding Leather and Vinyl Sewing

For those considering adding a zig zag stitch machine to their sewing toolkit, it’s important to recognize the range of options available on the market. Modern machines often come equipped with a myriad of additional features, such as automatic threading, a variety of stitch patterns, and built-in tutorials. These advancements make it easier for both beginners and experienced seamstresses to harness the potential of the zig zag stitch.

Additionally, chain stitch seams are known for their strength. Unlike other stitching methods, chain stitches can bear significant tension without breaking, making them ideal for areas of garments subject to stress, such as armholes and seat seams. This durability not only enhances the lifespan of the garments but also reduces returns and complaints related to seam failures, which is beneficial for manufacturers.