Functionality of Electric Valves

Functionality of Electric Valves

Additionally, some stations incorporate safety mechanisms such as excess flow valves, which can close off gas supply if the flow rate exceeds a predetermined limit, as a response to pipe ruptures or major leaks. This feature is crucial for minimizing the risk of explosions and other dangerous incidents.

Understanding Natural Gas Pressure Reducers A Vital Component for Safety and Efficiency

- Enhanced Efficiency By effectively removing particulates and moisture, these filters improve the efficiency of downstream equipment, such as compressors and turbines. This leads to reduced energy consumption and operational costs.

One of the most significant applications of coalescing filters is in the oil and gas industry. In many situations, crude oil extracted from wells contains a significant amount of water, which can adversely affect the transportation and refining processes. By employing coalescing filters, operators can remove these unwanted water droplets before crude oil enters storage tanks or pipelines. This not only protects equipment but also enhances overall operational efficiency, leading to cost savings in transportation and refining.

1. Chemical Industry In the chemical manufacturing process, gases such as hydrogen, nitrogen, and ammonia are often stored in pressure vessels. Their ability to contain gases under high pressure is essential for both the production and storage phases.

Advancements in Filter Separator Technology

Importance of Proper Valve Selection

In addition to energy efficiency and data insights, smart regulators also offer enhanced convenience and control. Many smart regulators can be integrated with other smart devices and systems, such as home automation systems or smart grids, allowing for seamless communication and coordination between different components. This level of connectivity and automation can streamline processes, reduce human error, and create a more cohesive and efficient system overall.

At the heart of smart regulation is the use of big data and analytics. Traditional regulatory approaches often rely on static rules and manual oversight, which can lead to inefficiencies and slow responses to emerging challenges. In contrast, smart regulators harness data from multiple sources—ranging from social media to IoT devices—to gain real-time insights into activities within their jurisdictions. This data-driven approach allows regulators to identify trends, anticipate issues before they escalate, and implement timely interventions.

4. Cost-Effectiveness Investing in the right type of shut-off valve can result in long-term savings by reducing the need for repairs, replacements, and operational inefficiencies.

In recent years, technological advancements have expanded the capabilities of safety valves. Innovations such as electronic monitoring and control systems allow for real-time tracking of pressure levels and valve performance, leading to improved reliability and preventive maintenance strategies. Predictive maintenance techniques also help in identifying potential issues before they escalate, further safeguarding operations.

The breather valve is designed to automatically open when the pressure inside a system exceeds a certain set point. This ensures that the equipment is not damaged or compromised due to excessive pressure. In addition to releasing pressure, the breather valve also prevents the formation of a vacuum by allowing air to enter the system when needed.

The Importance of Gas Pressure Reducers

Conclusion

Moreover, Tesla's approach to supercharging is innovative and user-friendly. The design of supercharging stations often includes multiple charging stalls, allowing several cars to charge simultaneously. This not only minimizes waiting times but also promotes a sense of community among EV drivers. Additionally, many supercharger locations are strategically placed near amenities like coffee shops and restaurants, allowing drivers to use their charging time productively.

In conclusion, gas safety valves are an indispensable aspect of gas system operations. Their ability to prevent gas leaks and manage system pressure significantly contributes to overall safety in both residential and industrial settings. As technology advances, we may see further innovations in valve design and functionality, enhancing their responsiveness and reliability. Ultimately, the ongoing commitment to safety in the gas industry ensures that these critical components continue to protect lives and property from the hazards associated with gas systems.

At its core, a gas pressure regulator is a mechanical device that reduces the pressure of the incoming gas to a predetermined output pressure. This is particularly important because gases are often supplied at relatively high pressures, which can be dangerous if not managed properly. By regulating the pressure, the device helps prevent potential accidents, such as leaks or explosions, that can occur if the pressure is too high.

Regulatory Standards and Compliance

Understanding Pressure Reduction Valves A Comprehensive Guide

Gas metering involves the process of measuring the quantity of gas consumed by residential, commercial, or industrial users through specialized devices known as gas meters. These meters provide essential data that enables utilities to bill customers accurately, manage supply and demand, and ensure the efficient delivery of gas.

Applications and Benefits

Despite these challenges, LPG remains a critical component of the global energy mix. Its adaptability and efficiency provide a bridge towards more sustainable energy sources while addressing immediate energy needs. Governments and organizations are increasingly recognizing the potential of LPG to facilitate a smoother transition to renewable energy sources by serving as a reliable backup during the shift.

- Cooking and Residential Appliances Home appliances, such as gas ranges and water heaters, rely on GPRVs to control gas pressure to ensure safe and efficient operation.

3. Environmental Safety In addition to protecting people and infrastructure, safety valves are crucial for environmental safety. Gas leaks can lead to greenhouse gas emissions, contributing to climate change. By preventing leaks and managing system pressure, safety valves help minimize environmental impacts.

Overall, gas pressure reduction stations play a vital role in ensuring the safe and reliable distribution of natural gas to end-users. These stations help to protect downstream equipment, optimize the performance of gas distribution systems, and provide a consistent supply of natural gas for residential, commercial, and industrial applications. Without gas pressure reduction stations, the efficient transportation and use of natural gas would not be possible.

4. Double-Pipe Heat Exchangers As the simplest design, this type consists of one pipe fitted inside another. One fluid flows through the inner pipe, while the other flows through the outer shell. Though less efficient than other designs, double-pipe heat exchangers are straightforward to install and maintain.

In conclusion, gasifiers represent a dynamic and transformative technology within the realm of energy production. By converting diverse feedstocks into syngas, these devices offer a multifaceted solution to energy generation, waste management, and emissions reduction. As the world increasingly shifts towards sustainable practices, gasification stands poised to play a crucial role in shaping a cleaner, more resilient energy future.

3. Industrial Factories and manufacturing plants use gas regulators to manage gas supply for processes and machinery, ensuring optimal production conditions.

A natural gas regulator is a device designed to control the pressure of natural gas as it moves from a higher pressure area — typically the main pipeline — to a lower pressure area, such as a home or business appliance. This regulation is necessary because natural gas is transported at high pressures to ensure that it reaches far distances efficiently. Once the gas reaches its destination, it must be reduced to a safe and manageable pressure for use in appliances, heating systems, and other applications.

2. Metering Regulators Positioned downstream of the line pressure regulators, metering regulators are responsible for maintaining a specific pressure before the gas enters individual appliances. They ensure that each device receives the optimal amount of gas needed for efficiency and safety.

3. Reduced Labor Costs By automating the regulation of flow, companies can minimize labor costs associated with manual valve operation. Maintenance requirements are also reduced, as electric valves can operate without the constant supervision needed for manual systems.

One of the most widely recognized pressure relief devices is the specialized mattress or mattress overlay. These products are designed to redistribute body weight and reduce pressure points, significantly lowering the risk of developing bedsores. Advanced options include alternating pressure mattresses, which use air cells that inflate and deflate cyclically to enhance circulation and relieve pressure. These innovative solutions are essential in hospitals and long-term care facilities where patients spend substantial amounts of time in bed.

Functionality of Electric Regulating Valves

clear low e glass. It blocks up to 70% of the harmful ultraviolet rays, thereby protecting furniture, carpets, and artwork from fading due to prolonged exposure to sunlight.

clear low e glass. It blocks up to 70% of the harmful ultraviolet rays, thereby protecting furniture, carpets, and artwork from fading due to prolonged exposure to sunlight. It showed not only the reflections of the present but also the echoes of the past It showed not only the reflections of the present but also the echoes of the past

It showed not only the reflections of the present but also the echoes of the past It showed not only the reflections of the present but also the echoes of the past brown reflective glass. The building had a history, a narrative etched into its very foundation. It had witnessed countless lives and stories, each leaving an imprint on its surface.

brown reflective glass. The building had a history, a narrative etched into its very foundation. It had witnessed countless lives and stories, each leaving an imprint on its surface.

silver mirror suppliers. Many suppliers uphold techniques passed down through generations, combining modern technology with artisanal expertise. They take pride in their ability to create bespoke mirrors that align with specific requirements, from size and shape to frame design and finishing.

silver mirror suppliers. Many suppliers uphold techniques passed down through generations, combining modern technology with artisanal expertise. They take pride in their ability to create bespoke mirrors that align with specific requirements, from size and shape to frame design and finishing.The Allure of Real Silver Mirrors

Additionally, low-e glass panels can help to improve the comfort of occupants within a building. By maintaining a more consistent indoor temperature, these panels can create a more pleasant living or working environment. They can also reduce glare and block harmful UV rays, which can help protect furniture and other belongings from sun damage.

4. UV Protection Tempered insulated glass units can be treated with low-emissivity (low-E) coatings, which block a significant percentage of harmful ultraviolet (UV) rays. This protection helps prevent fading of furniture, flooring, and artwork indoors, extending the lifespan of these items.

The history of pattern glass can be traced back to the 19th century when it gained popularity during the Victorian era. The introduction of new manufacturing techniques, such as glass pressing, allowed artisans to create intricate designs that were both beautiful and affordable. This made decorative glass accessible to a wider audience. Over time, pattern glass became a staple in homes, used for everything from windows to tableware.

1. Safety and Durability One of the most significant advantages of tempered glass is that it is much tougher than regular glass. When shattered, tempered glass breaks into small, blunt pieces, reducing the risk of injury. This safety feature makes it an ideal choice for various applications, including windows, doors, and shower enclosures.

Automotive Industry

tinted glass material. The degree of transparency can be adjusted according to need, allowing for a balance between visibility and seclusion. In residential settings, this can be particularly useful for bedrooms or bathrooms, while in commercial spaces, it can create a professional ambiance without compromising on light.

tinted glass material. The degree of transparency can be adjusted according to need, allowing for a balance between visibility and seclusion. In residential settings, this can be particularly useful for bedrooms or bathrooms, while in commercial spaces, it can create a professional ambiance without compromising on light.Glass curtain wall: glass curtain wall composed of glass ribs and glass panels. This kind of glass curtain wall has no metal skeleton from the facade, and the finishing materials and structural members are glass materials. Because of its large glass finish, so that the curtain wall has greater permeability, so it is often used in buildings.

- Shower Enclosures In bathrooms, tempered insulated glass is ideal due to its safety qualities and resistance to temperature changes.

Photovoltaic glass definition and classification

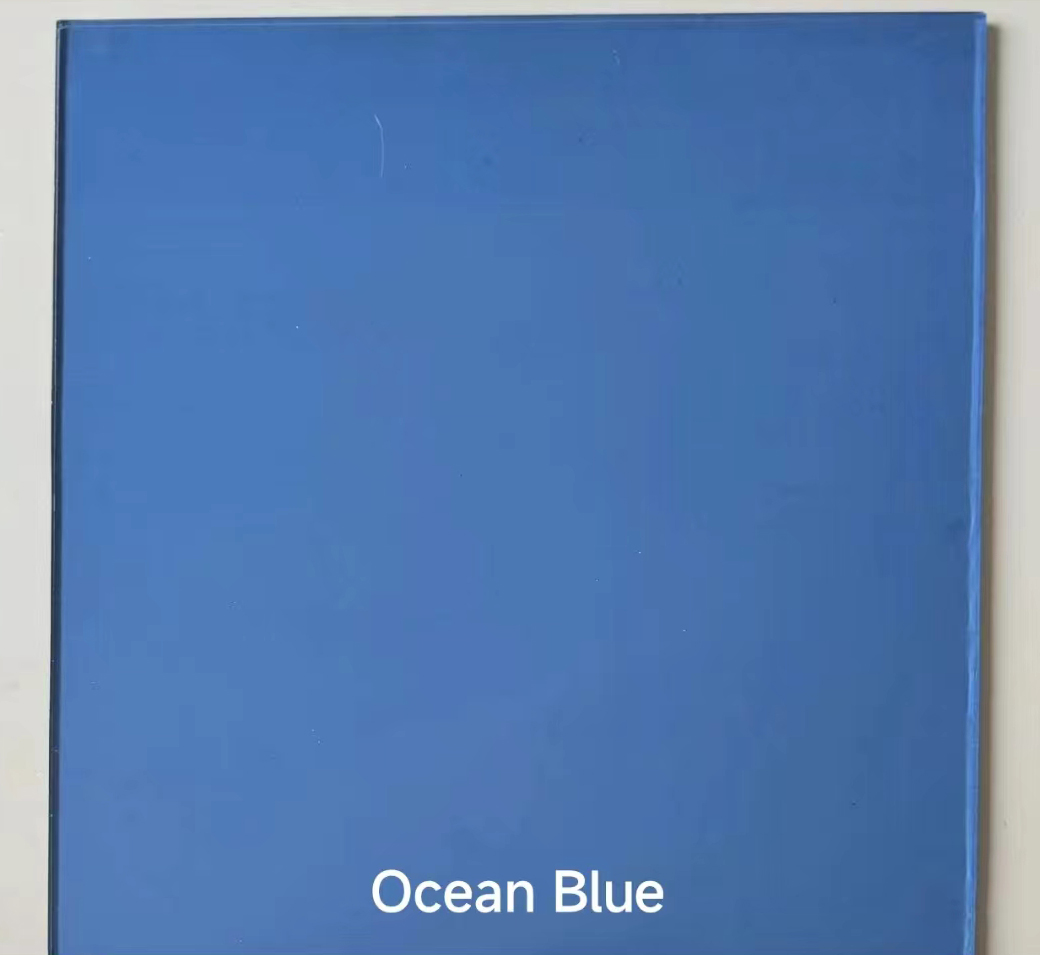

One of the key benefits of reflective blue glass is its ability to enhance natural light in a space. The reflective surface of the glass helps to bounce light around a room, creating a bright and airy atmosphere. This makes reflective blue glass an ideal choice for spaces that lack natural light, such as interior rooms or buildings with limited windows.

1. Enhanced Safety One of the primary advantages of tempered glass is its safety characteristics. In the event of a breakage, tempered glass shatters into small, blunt pieces that are less likely to cause injury compared to standard glass, which can break into sharp shards. This safety feature is crucial in applications like windows, shower enclosures, and glass railings.

This means that you can enjoy the benefits of fresh air and natural light without constantly worrying about maintenance or repairs This means that you can enjoy the benefits of fresh air and natural light without constantly worrying about maintenance or repairs

This means that you can enjoy the benefits of fresh air and natural light without constantly worrying about maintenance or repairs This means that you can enjoy the benefits of fresh air and natural light without constantly worrying about maintenance or repairs low e rated windows.

low e rated windows.The History of Bubble Pattern Glass

Photovoltaic modules with ultra-white glass