The Role of Smart Regulators in Modern Governance

The Role of Smart Regulators in Modern Governance

1. Safety One of the primary reasons for using gas pressure reducers is safety. High-pressure gas can be hazardous, potentially leading to explosions or equipment failures. By maintaining a safe operating pressure, these devices mitigate risks and enhance workplace safety.

There are several types of gas-to-gas heat exchangers, including shell and tube heat exchangers, plate heat exchangers, and finned tube heat exchangers. Each type has its advantages and limitations depending on the specific requirements of the application. For example, shell and tube heat exchangers are commonly used in high-pressure and high-temperature applications due to their robust construction and ability to handle a wide range of operating conditions.

In various industrial applications, effective separation of gas and liquid phases is crucial for optimizing processes and ensuring equipment longevity. Among the technologies employed to achieve this separation, gas coalescer filters stand out due to their efficiency in removing water and particulate contaminants from gas streams. This article delves into the concept of gas coalescer filters, their operation, benefits, and applications.

The importance of pressure regulation cannot be overstated. Pressure reducing valves are integral to modern infrastructure, promoting safety, enhancing equipment efficiency, and ensuring reliable service across various applications. Understanding their function and significance can lead to better management and design of systems that depend on controlled pressure, ultimately benefiting both users and providers alike. By investing in quality PRVs, industries can protect their assets, improve performance, and contribute to safer operational environments.

The infrastructure for CNG fueling stations is also evolving rapidly, fostering its adoption in both public and private transportation sectors. While historically limited, many nations are investing in expanding the CNG refueling network to support the growing number of CNG vehicles on the road. Various governments are even providing financial incentives for building CNG stations, thus accelerating the transition toward a more sustainable transport system. Fleets of buses, trucks, and taxis are gradually converting to CNG, drawn by its cost advantages and environmental benefits.

The Future of Natural Gas Valves

Yet, it is essential to recognize that these distinctions do not necessitate isolation. Al-faṣl allows for the appreciation of diversity within unity. It emphasizes that while differences exist, they can coexist harmoniously. The challenge for individuals and societies lies in navigating these separations with empathy and understanding, forging connections that transcend boundaries.

1. Coalescing Filters These filters are used to remove liquid water and particulates from gas streams. They work by promoting the coalescence of fine water droplets into larger ones, which can then be easily separated from the gas.

Natural Gas Pressure Reduction Stations An Overview

4. Regenerative Heat Exchangers These systems store heat from a hot gas stream and release it to a cooler gas stream later in the cycle, enhancing efficiency in systems with fluctuating heat requirements.

Despite their importance, gas distribution stations face several challenges. Aging infrastructure is a significant concern in many regions where facilities have not been updated to meet modern safety and efficiency standards. Moreover, as the world shifts toward renewable energy sources, there is ongoing debate about the future role of natural gas in the energy mix.

Furthermore, these stations are often designed with the community in mind, featuring amenities that enhance the user experience. Many incorporate retail spaces, restaurants, and public facilities such as waiting lounges and restrooms. Additionally, they often include features aimed at improving accessibility for all, such as elevators, ramps, and clear signage in multiple languages. This focus on user-centric design not only benefits commuters but also reinforces the station’s role as a communal space where people gather, socialize, and connect.

There are several types of gas pressure regulators, each designed for specific applications. The most common types include

Understanding the Coalescing Filter Functionality and Applications

The natural gas sector is a significant contributor to the global economy. According to various reports, it supports millions of jobs worldwide, from engineering and construction to logistics and sales. Natural gas organizers play a pivotal role in this economic landscape by ensuring that operations are conducted efficiently, thus maximizing profitability while minimizing risks.

LPG is primarily produced during the refining of crude oil and the natural gas extraction process. This substance is stored and transported in liquid form under pressure, which allows for efficient handling and storage. When released from pressure, LPG vaporizes and can be used as a clean-burning fuel. The ability to liquefy gas makes transportation to remote areas economically viable, thereby increasing its accessibility.

The implementation of gas filtration systems provides numerous benefits for industries, including

- Compliance Many regions have stringent regulations regarding gas supply systems to ensure safety. Proper installation and maintenance of pressure regulators are often part of compliance with these safety standards.

Conclusion

2. Tankless Water Heaters Also known as on-demand water heaters, tankless models heat water directly without the use of a storage tank. When a hot water tap is turned on, cold water travels through a pipe into the unit, where it's heated by electric coils. This type of heater offers several advantages, including a longer lifespan, greater energy efficiency, and an endless supply of hot water since it only heats water when needed. However, tankless water heaters come at a higher initial cost and may require upgrades to your electrical system.

In conclusion, coalescing filters are a vital component in various industrial applications due to their efficiency in removing liquid contaminants from gases. Their ability to enhance equipment performance, lower operational costs, and promote environmental sustainability makes them indispensable in modern engineering practices. As industries continue to evolve and place more emphasis on efficiency and environmental responsibility, the demand for effective filtration solutions like coalescing filters is expected to grow. Understanding their functionality and applications is essential for engineers and professionals striving to improve processes while safeguarding the environment.

1. Pressure Regulators The heart of any pressure regulating skid, these devices adjust the pressure of the fluid to a predetermined level, ensuring consistent and safe operation. Regulators can manage both upstream and downstream pressure, adapting to changes in flow rates and system demands.

Philosophically, Al-Muthbit also highlights the quest for truth. The verification process in philosophy parallels that in science, where empirical evidence is foundational. Just as scientists must establish theories based on rigorous testing and validation, philosophers seek to affirm their ideas through logical reasoning and discourse. This parallel showcases how the quest for knowledge—whether in matters of faith, law, or philosophy—requires a commitment to establishing and confirming truths.

1. Globe Valves These valves provide good throttling capabilities and are widely used for regulating flow. Their design allows for a significant restriction, making them ideal for applications where precise control is essential.

The significance of relief valves cannot be overstated. Overpressure situations can lead to catastrophic failures, including explosions, equipment damage, and even injuries or fatalities. By preventing these scenarios, relief valves contribute to operational efficiency and safety.

Finally, it is crucial to remain adaptable. In today’s fast-paced business environment, the ability to pivot and reorganize as market conditions evolve can be the difference between success and failure. Businesses that regularly assess their organizational structure and make necessary adjustments are more likely to thrive.

By removing oil and water droplets from the gas stream, coalescing filters enhance the efficiency and longevity of the gas processing system By removing oil and water droplets from the gas stream, coalescing filters enhance the efficiency and longevity of the gas processing system

By removing oil and water droplets from the gas stream, coalescing filters enhance the efficiency and longevity of the gas processing system By removing oil and water droplets from the gas stream, coalescing filters enhance the efficiency and longevity of the gas processing system coalescing filter.

coalescing filter.One of the most significant advantages of gasification is its potential to reduce greenhouse gas emissions. When biomass is used as feedstock, the carbon dioxide released during gasification is roughly equal to the amount absorbed by the plants during their growth, resulting in a closed carbon loop. This makes gasification a carbon-neutral process, provided it is managed sustainably.

The Rise of Superchargers Revolutionizing Electric Vehicle Charging

The importance of gas pressure regulators cannot be overstated. They enhance safety by preventing excess pressure that could lead to leaks or explosions. By maintaining consistent pressure, they also improve the efficiency and longevity of gas-powered appliances and equipment. Furthermore, by ensuring optimal operating conditions, they contribute to energy conservation, reducing unnecessary gas consumption and emissions.

The working principle of a pressure reducing device can be understood through its main components the inlet pressure port, the outlet pressure port, and the regulating mechanism

. When a high-pressure fluid enters the device, a sensing element within the regulator detects the pressure and adjusts the mechanism to maintain the desired output pressure. This is typically achieved through a spring-loaded diaphragm or piston that responds to changes in pressure. sewer jetter near me. Modern sewer jetters use advanced technology with variable pressure settings, allowing them to adapt to different pipe materials and sizes. Ask if they have the latest tools and if they perform regular maintenance on their machinery to guarantee optimal performance.

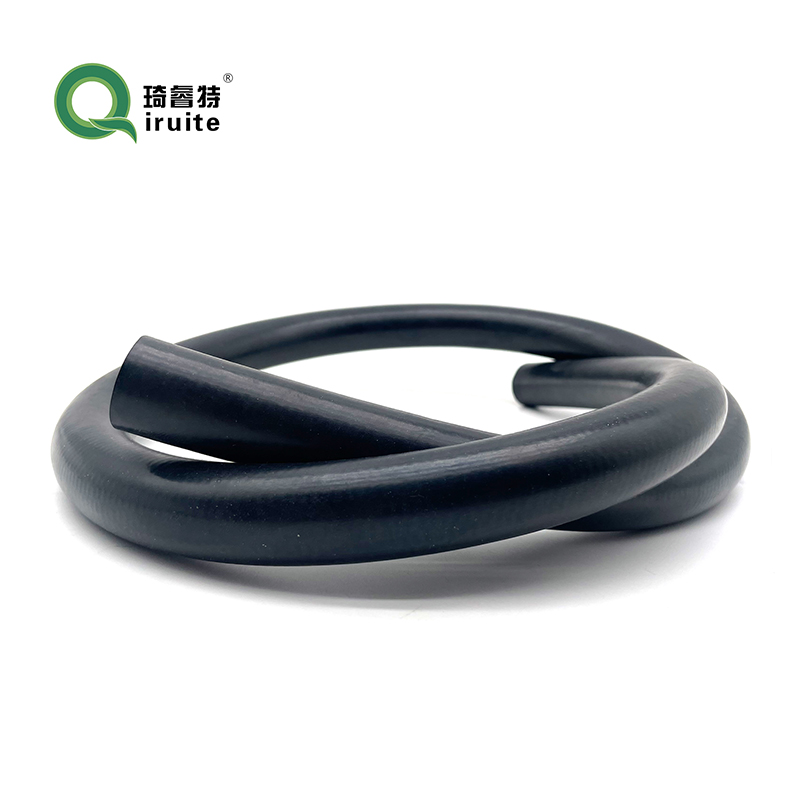

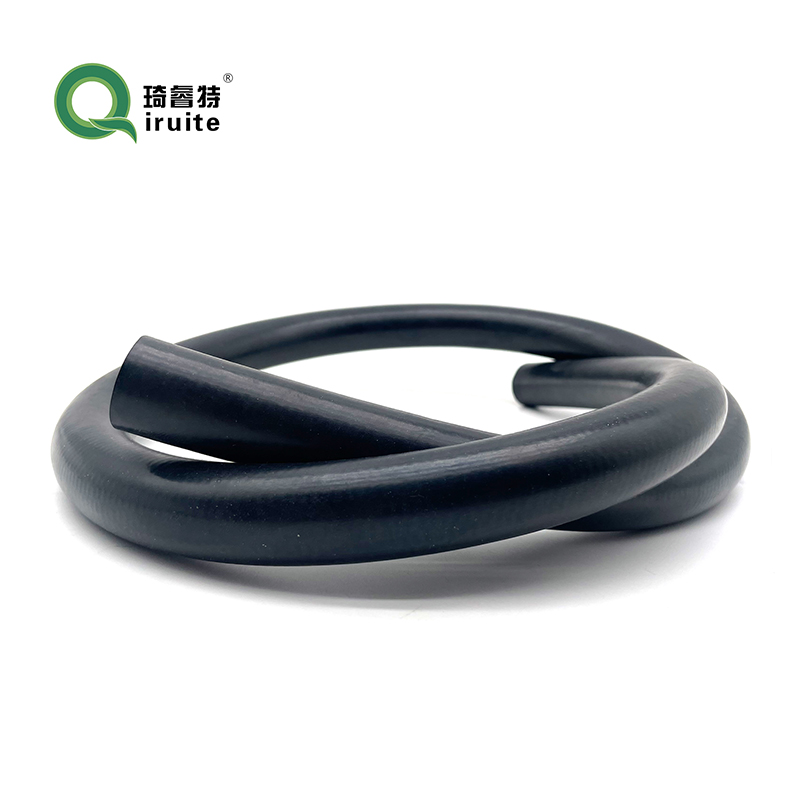

sewer jetter near me. Modern sewer jetters use advanced technology with variable pressure settings, allowing them to adapt to different pipe materials and sizes. Ask if they have the latest tools and if they perform regular maintenance on their machinery to guarantee optimal performance. The inner liner provides a seal against the leakage of hydraulic fluid, while the reinforcement layers improve the hose's strength and resistance to pressure and abrasion The inner liner provides a seal against the leakage of hydraulic fluid, while the reinforcement layers improve the hose's strength and resistance to pressure and abrasion

The inner liner provides a seal against the leakage of hydraulic fluid, while the reinforcement layers improve the hose's strength and resistance to pressure and abrasion The inner liner provides a seal against the leakage of hydraulic fluid, while the reinforcement layers improve the hose's strength and resistance to pressure and abrasion gen 2 power steering hose. The outer cover offers protection against environmental factors such as UV radiation, ozone, and chemicals.

gen 2 power steering hose. The outer cover offers protection against environmental factors such as UV radiation, ozone, and chemicals.