The significance of natural gas safety valves cannot be overstated

. They serve several critical functions

The significance of natural gas safety valves cannot be overstated

. They serve several critical functions

- Diving and Aviation In recreational diving, pressure vessels are used to store breathing gases, such as compressed air or specialty gas mixtures. Similarly, in aviation, gas cylinders are employed for various functions, including cabin pressurization.

Conclusion

- Power Generation They are critical in power plants for steam generation and cooling processes, enhancing the overall efficiency of energy production.

Moreover, cyclone separators are environmentally friendly. They help minimize pollution by capturing airborne dust and particulate matter before it can be released into the atmosphere. By reducing dust emissions, industries can comply with environmental regulations and contribute to cleaner air quality.

مزلقة تخفيف الضغط. Engaging in tasks like eating, walking, or even washing dishes with full attention can turn these mundane acts into opportunities for relaxation. By doing so, we create a mental break from the stressors of life, enhancing our ability to cope.

مزلقة تخفيف الضغط. Engaging in tasks like eating, walking, or even washing dishes with full attention can turn these mundane acts into opportunities for relaxation. By doing so, we create a mental break from the stressors of life, enhancing our ability to cope.

Pressure relief valves find applications across numerous industries. In healthcare, they are used in steam sterilizers to prevent overpressure. In the food industry, they ensure that pressure vessels used in food processing operate safely. The chemical industry relies on these valves to protect reactors and storage tanks from potentially dangerous pressure spikes.

3. Air-to-Air Heat Exchangers Commonly used in HVAC systems, these devices facilitate heat transfer between two air streams. They are often employed in energy recovery ventilators to improve indoor air quality while minimizing thermal losses.

Gas pressure regulators are critical components in various industries, serving as crucial devices that ensure the safe and efficient use of gases. These regulators are designed to maintain a consistent output pressure regardless of fluctuations in the inlet pressure or the demand on the system. This functionality is essential for a range of applications where controlled gas pressure is necessary for operational safety and efficiency.

Significance of Gas Pressure Vessels

Moreover, pneumatic control valves are characterized by their durability and reliability

. They are typically designed to handle high pressures and can function effectively in extreme temperatures. This resilience makes them suitable for demanding environments, such as factories and warehouses, where they contribute to efficient workflow and increased productivity.When installing or maintaining gas regulators, it is essential for users to adhere to safety standards and regulations. Professional installation by qualified personnel is critical to ensure the proper functioning of the system. Regular inspections and maintenance are also required to identify and rectify any potential issues before they escalate.

1. Efficiency By standardizing pressure management in a modular format, skids can enhance overall system efficiency while reducing installation time.

Regular maintenance is also crucial for the longevity of gas pressure vessels. Periodic inspections help identify early signs of wear and tear, corrosion, or other issues that could compromise safety. Advanced monitoring technologies, such as pressure sensors and automated safety shutoff systems, are increasingly being integrated into modern pressure vessel designs. These technologies provide real-time data, allowing operators to address potential issues before they escalate.

What is a Natural Gas Regulator?

Operational Principles

The importance of safety relief valves cannot be overstated. They are essential for maintaining the integrity of processes and ensuring the safety of personnel. Without SRVs, equipment would be at risk of severe damage, which could result in costly repairs, downtime, and potential hazards to human life. Not only do safety relief valves mitigate risks associated with overpressure, but they also contribute to environmental protection by preventing leaks of hazardous substances.

Challenges and Considerations

Gas pressure vessels are essential components used in various industries to store and manage gases at pressures higher than atmospheric levels. These vessels are designed to withstand significant internal pressures while ensuring safety and efficiency in their operations. This article delves into the concepts surrounding gas pressure vessels, including their design principles, applications, and safety measures.

Gas regulators can be classified into several categories based on their intended application

Construction and Materials

Safety is a paramount consideration in the design and operation of PRS. These stations are equipped with multiple safety valves and monitoring systems that ensure any irregularities are swiftly addressed. Moreover, pressure relief valves are installed to prevent over-pressurization, which can lead to catastrophic failures.

4. Double-Pipe Heat Exchangers The simplest design consists of one pipe inside another, with one fluid circulating through the inner pipe and another through the outer pipe. They are easy to design and manufacture, making them suitable for small-scale applications.

In the contemporary dialogue surrounding energy resources and environmental sustainability, Compressed Natural Gas (CNG) has emerged as a significant player. As the world grapples with the pressing challenges of climate change and the depletion of traditional fossil fuels, CNG presents a viable alternative that combines economic efficiency with a reduced carbon footprint. This article explores what CNG is, its benefits, and the role it can play in a sustainable energy future.

One of the key advantages of natural gas is its capacity to bridge the gap between traditional fossil fuels and renewable energy sources. As countries transition towards a low-carbon future, natural gas can serve as a reliable backup for intermittent renewable energies such as wind and solar. Natural gas power plants can quickly ramp up or down in response to fluctuations in energy demand and supply, providing stability to the grid and ensuring that energy remains available even when renewable sources are not producing power.

There are several types of safety valves specifically designed for natural gas applications

Gas heat exchangers are employed across various industries including automotive, aerospace, power generation, and manufacturing. In power plants, they are used to recover waste heat from exhaust gases, which can then be converted into useful energy, enhancing the overall efficiency of the plant.

Conclusion

The financial implications of implementing gas filtration systems are also noteworthy. While the initial investment in advanced filtering technology can be substantial, the long-term benefits often outweigh the costs. By reducing emissions, companies can avoid costly fines and penalties associated with non-compliance. Furthermore, effective gas filtration can lead to improved operational efficiency and lower energy costs, as cleaner emissions often result in better performance of machinery and equipment.

At its core, a pneumatic control valve regulates the flow of compressed air or gas, allowing operators to control pressure and flow rates within a system. This capability is vital for operations such as actuation, where the controlled movement of components is necessary. For example, pneumatic systems are commonly used to power cylinders that perform tasks like lifting, pushing, or clamping within machinery.

The Organization of Natural Gas A Vital Energy Resource

Concrete formwork accessories are vital components in the construction industry, ensuring the integrity and durability of concrete structures. From wall ties to rolled steel bars, these accessories play a crucial role in shaping and reinforcing concrete elements. This article delves into essential concrete formwork accessories, including wall ties for concrete, adjustable brick ties, and the benefits of using rolled steel bars.

hot dipped galvanized iron wire. The wire can be used to create support structures for plants, such as trellises or tomato cages. It can also be used to create animal enclosures, such as chicken coops or pig pens.

hot dipped galvanized iron wire. The wire can be used to create support structures for plants, such as trellises or tomato cages. It can also be used to create animal enclosures, such as chicken coops or pig pens.Concrete attachments are an important part of any construction project, ensuring structural integrity, ease of construction and overall efficiency. These accessories range from basic items such as form ties and rebar to more specialized products such as curing blankets and expansion joints. Their main purpose is to support and strengthen concrete structures, making them more durable and resilient. By integrating high-quality concrete accessories into construction projects, builders can achieve better alignment, reduce labor costs, and accelerate project timelines. Additionally, using the right fittings can help prevent common problems such as cracking, misalignment, and premature wear, thereby extending the life of your concrete structure.

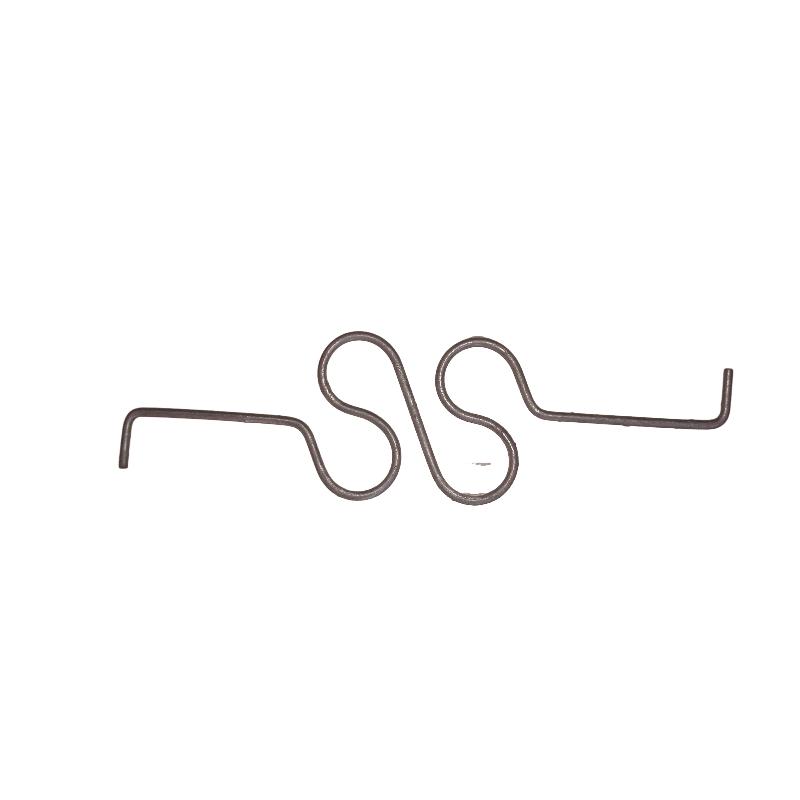

Wire grid panels, also known as wire grid displays , are commonly used in retail environments for showcasing products. These panels are versatile and can be configured in various ways to display items effectively. They are easy to install and reconfigure, making them ideal for dynamic retail spaces.Bricktor is a type of wire reinforcement used in masonry construction to enhance the strength and stability of brickwork. It is embedded in mortar joints to prevent cracking and improve structural integrity.

Galvanized annealed wire, on the other hand, is coated with a layer of zinc that provides excellent protection against rust and corrosion, making it ideal for construction, fencing, and agricultural applications.

In conclusion, extension springs play a vital role in many mechanical systems, providing the force required for extension and retraction. Available in a variety of designs and types, including loop ends, hook ends, custom options, and expansion springs, these components provide versatile solutions for a variety of applications. Understanding the different hook types and designs can help select the extension spring that best suits your specific engineering and manufacturing needs.

brick end ties. This is because they provide a cost-effective and reliable solution for joining bricks, while also adding an aesthetically pleasing touch to the final structure. The intricate patterns created by these ties can add depth and character to a building, making it truly unique.

brick end ties. This is because they provide a cost-effective and reliable solution for joining bricks, while also adding an aesthetically pleasing touch to the final structure. The intricate patterns created by these ties can add depth and character to a building, making it truly unique.Improve seismic performance: high-quality and suitable connectors help improve the seismic resistance of walls in natural disasters such as earthquakes and reduce the degree of damage.