Pressure reducing regulators can be classified into two main categories single-stage and two-stage regulators.

Pressure reducing regulators can be classified into two main categories single-stage and two-stage regulators.

City Gate Station A Nexus of Urban Connectivity

2. Equipment Protection Many devices, such as pumps, boilers, and pipelines, are designed to operate within specific pressure ranges. A pressure reducing valve safeguards these components from damage caused by pressure spikes or surges, thus extending their lifespan and reducing maintenance costs.

Pneumatic control valves come in various types, each designed for specific applications. Ball valves, butterfly valves, and solenoid valves are prevalent in pneumatic systems. Ball valves provide quick shut-off capabilities, while butterfly valves offer a more compact and lightweight solution for regulating flow. Solenoid valves, on the other hand, use electromagnetic coils to control flow, allowing for precise on-off switching in applications where automated control is required.

The operation of a PRV is based on a simple yet effective mechanical principle. When the inlet pressure exceeds the setpoint of the valve, the internal mechanism adjusts to reduce the pressure to the desired level. Typically, this involves the use of a spring-loaded diaphragm or piston that moves in response to changes in pressure. As the upstream pressure increases, the diaphragm is pushed against the spring force, causing the valve to partially close until the outlet pressure stabilizes at the preset value.

The primary function of a gas coalescer is to remove liquid droplets from a gas stream by causing the droplets to combine and form larger droplets, which can then be easily separated from the gas. This process is achieved through the use of a coalescing media, such as a mesh, which causes the droplets to merge and grow in size as they pass through the gas coalescer.

The growing ecosystem surrounding Flutter, including a robust community and extensive documentation, makes it easier for new developers to adopt the framework. Numerous packages and plugins are available to extend the functionality of Flutter applications, offering ready-made solutions that save development time and effort.

- Energy Efficiency Modern electric valves are designed to minimize energy consumption, contributing to overall system efficiency.

There are various designs and configurations of natural gas filter separators available, each suited for specific applications and operational conditions. The most common types include

Understanding the Importance of Natural Gas Safety Valves

Natural gas valves are fundamental components of the energy infrastructure that support the safe and efficient delivery of natural gas. Their various types serve distinct functions, catering to the diverse needs of the industry. As the global emphasis on energy efficiency and safety increases, the development of advanced valve technologies will continue to play a critical role in meeting these demands. Understanding the importance of these valves not only highlights their functional significance but also underscores the commitment to maintaining a secure and sustainable energy future. The advancements in valve technology are a testament to the industry's dedication to innovation, enabling us to harness the benefits of natural gas while prioritizing safety and environmental responsibility.

- Cost and Budget Consider both the initial purchase price and the operating costs. While tankless models offer energy savings, their upfront cost can be significantly higher than traditional tank heaters.

The design of coalescing filters typically includes various elements such as a pre-filter to capture larger particulates, coalescing media to facilitate the clustering of droplets, and a final filter to ensure that any remaining contaminants are effectively removed. It’s essential to regularly maintain and replace these filters to ensure optimal performance and prevent issues such as clogging or reduced efficiency in the fluid purification process.

One of the key advantages of using gas regulators is the improvement of safety in gas handling. Gas leaks can pose severe risks and consequences, including fires, explosions, and health hazards. Regulators often feature safety mechanisms, such as relief valves, that prevent excessive pressure buildup and automatically vent gas if necessary. This reduces the likelihood of accidents and enhances the overall safety profile of industrial operations.

2. Comparison and Analysis Accurate measurements allow for effective comparison between different entities, leading to informed decision-making. For instance, in manufacturing, comparing measurements of component parts is crucial for quality control.

1. Preventing Explosions One of the most pressing dangers associated with natural gas is the risk of explosions caused by pressure build-up. Safety valves automatically activate to release gas when pressure exceeds a predetermined limit, thereby preventing dangerous situations.

What is a Heat Exchanger?

Regulatory Standards

A natural gas filter separator is a mechanical device designed to separate liquid and solid contaminants from natural gas streams. These contaminants can include water, oil, dirt, and other particulate matter that can adversely affect the efficiency and reliability of gas processing systems. The filter separator operates primarily through two processes filtration and separation.

At the heart of a pressure reducing valve is a mechanism that modulates the flow of fluid based on the pressure differential between the inlet and outlet. When the upstream pressure exceeds a predetermined set point, the valve will automatically adjust to allow more flow, thereby reducing the pressure downstream. Conversely, if the downstream pressure falls below the set point, the valve will constrict flow to maintain the desired pressure level.

Types of Gas Regulators

1. Directional Control Valves These valves manage the path that air takes within a system. They can control the switching between different actuators and are commonly used in applications requiring precise movement, such as robotics and automation.

Superchargers are high-capacity charging stations designed to deliver rapid energy transfers to electric vehicles, significantly reducing the time required to recharge. While traditional home charging systems can take several hours to fully charge an EV, superchargers can replenish up to 80% of a vehicle’s battery in as little as 30 minutes. This dramatic decrease in charging time makes long-distance travel in electric vehicles a more feasible and attractive option for consumers.

Importance in Natural Gas Processing

The Importance of Safety Valves A Comprehensive Overview

One of the primary reasons for using pressure regulators is safety. High-pressure natural gas can pose serious risks if it is not managed properly. Leakages or ruptures can lead to explosions or fires, potentially causing extensive damage to property and injury to individuals. By controlling the pressure and ensuring it remains within safe limits, regulators play a vital role in preventing such hazards.

The Importance of Metering Systems in Modern Infrastructure

Understanding Natural Gas Regulators

1. Equipment Protection By trapping large particles and impurities, basket strainers safeguard pumps, valves, and other critical equipment from abrasion and clogging. This prolongs the lifespan of the machinery and minimizes repair costs.

The construction of a pressure reducing regulator typically includes an inlet connection, an outlet connection, a body housing, a valve mechanism, and an adjustment screw. The adjustment screw allows users to set the desired outlet pressure by compressing or releasing the spring tension. Users must select the appropriate type of regulator based on specific application requirements, including the type of media (gas or liquid), pressure ranges, and flow rates.

The Rise of Superchargers Revolutionizing Electric Vehicle Charging

Effective gas metering provides a variety of benefits. Firstly, it allows for accurate billing, ensuring that consumers only pay for the gas they actually use. This accuracy is critical for both utility companies and customers, as discrepancies can lead to disputes and dissatisfaction. Furthermore, accurate metering is essential for energy management strategies that seek to optimize consumption and reduce waste.

In addition to maintaining high quality, the Concrete Nail Factory prioritizes sustainability. With the increasing emphasis on environmental responsibility, the factory adopts eco-friendly practices such as recycling scrap metal and reducing waste. Efforts to minimize energy consumption during production also reflect the factory's commitment to sustainable manufacturing. By incorporating these practices, the factory not only contributes to the welfare of the environment but also appeals to a growing base of environmentally conscious consumers.

2. Residential Security Homeowners can benefit from installing galvanized wire mesh as a boundary around their property. Its visibility allows owners to maintain awareness of any movement near their premises while providing a reliable barrier against intruders.

Beyond safety, field netting plays a role in enhancing the overall gameplay experience. For players, an enclosed environment facilitated by effective netting fosters a sense of immersion and focus. With the game confined to its designated space, players can concentrate on strategy and competition without distractions from outside elements. Furthermore, proper netting design can help maintain boundaries and create a clearly defined playing area, reducing the risk of players inadvertently wandering outside of the designated field during intense gameplay.

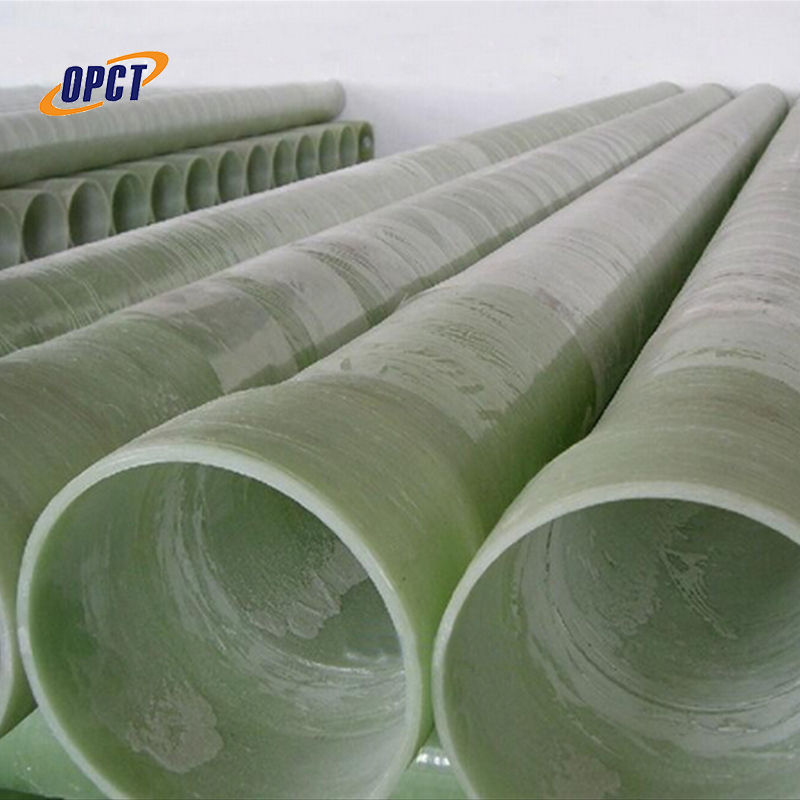

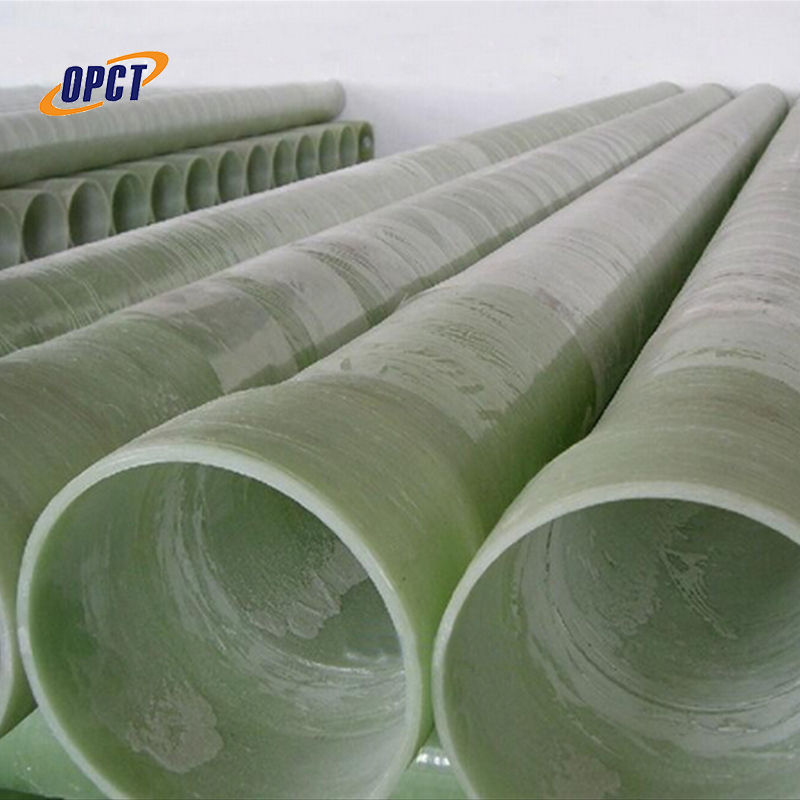

The significance of the fiberglass production line extends beyond mere manufacturing efficiency. It plays a vital role in meeting the rising demand for sustainable materials. As industries strive towards greener practices, fiberglass, known for its recyclability and lower environmental footprint compared to traditional materials, has become a preferred choice. Moreover, innovations within the production line, including the use of recycled glass as raw material, reflect a shift towards sustainable manufacturing practices.

Chemical tank storage plays a crucial role in various industries, from pharmaceuticals and agriculture to food production and energy. These storage systems are vital for safely keeping liquid chemicals, ensuring that businesses can operate efficiently while minimizing risks to human health and the environment. In this article, we will explore the key aspects of chemical tank storage, including types of tanks, safety measures, regulatory requirements, and best practices.

Advantages of Using Electric Galvanized Barbed Wire

Due to its properties, crusher crimped woven wire mesh is widely utilized in numerous applications

In conclusion, the 2x4 welded wire mesh is a versatile and durable material that offers a wide range of applications in various industries. Its strength, flexibility, and corrosion resistance make it an ideal choice for projects where structural integrity and longevity are essential. Whether used in construction, agriculture, landscaping, or any other industry, the 2x4 welded wire mesh is sure to deliver consistent performance and reliable results.

A 300-gallon stainless steel water tank also offers superior thermal insulation compared to other materials. Stainless steel can help maintain water temperature, which is beneficial in various contexts, such as aquaculture or for hot water systems. This temperature stability can enhance efficiency and provide better overall performance for your needs.

Conclusion

Eco-Friendly Solution

1. Construction Industry In construction, binding galvanized wire is extensively used for tying rebar (reinforcing bar) and securing building materials. Its strong binding capability ensures that structures remain stable and resilient during the construction process. Additionally, it is also utilized for forming shapes and frameworks in concrete applications.

This makes it an ideal choice for applications in harsh environments, such as offshore oil rigs, chemical processing plants, and wastewater treatment facilities This makes it an ideal choice for applications in harsh environments, such as offshore oil rigs, chemical processing plants, and wastewater treatment facilities

This makes it an ideal choice for applications in harsh environments, such as offshore oil rigs, chemical processing plants, and wastewater treatment facilities This makes it an ideal choice for applications in harsh environments, such as offshore oil rigs, chemical processing plants, and wastewater treatment facilities molded fiberglass grating.

molded fiberglass grating.The Air Concrete Nail Gun Revolutionizing Construction

PVC welded wire mesh is produced by welding together parallel and perpendicular wires to create a grid-like pattern. The welding process ensures that the connections are strong and secure, providing high structural integrity. After welding, the mesh is coated with PVC, which not only enhances its longevity but also adds a layer of protection against various elements. The thickness of the wire and the size of the mesh openings can be customized according to specific requirements, making it suitable for a wide range of applications.

Additionally, screw coil nails are less likely to split wood compared to standard nails, which is especially important when working with thin or delicate materials. This characteristic makes them a preferred choice for builders who aim for clean and aesthetic finishes. They also offer a reduction in the chance of damage to the surrounding materials, providing a smoother installation process.

The term 6x6 refers to the spacing of the wire intersections, which is 6 inches apart both vertically and horizontally. This fencing comprises high-quality, welded wire, providing a sturdy barrier that can withstand various environmental pressures. The wire is coated with protective materials, such as galvanization, preventing rust and extending the lifespan of the fence.

Conclusion

In conclusion, large nails encapsulate more than just a passing trend; they symbolize beauty, culture, empowerment, and individuality. Through bold self-expression, people are reshaping the conversation around beauty standards and fostering a greater appreciation for diversity in personal styles. As this trend continues to evolve, it will undoubtedly pave the way for new forms of creativity and self-identity, allowing individuals to express their unique narratives through the art of nail design. So, whether it’s an elegant stiletto or a playful coffin shape, large nails will continue to captivate and inspire, inviting all to embrace their distinct beauty.

What is a Concrete Nail Gun?

Furthermore, fiberglass anchor rods are non-conductive, which is another crucial advantage in specific applications. In areas where electromagnetic interference is a concern, such as in telecommunications or certain industrial settings, non-conductive materials are invaluable. The use of fiberglass minimizes the risk of electrical hazards, contributing to overall safety in construction projects.

In summary, wooden nails are more than just an old-fashioned fastener; they represent a rich tapestry of history, sustainability, and craftsmanship. Their ability to blend functionality with aesthetics makes them a valuable component in both traditional and contemporary woodworking projects. As we move further into an era of conscious consumerism and environmental awareness, the once-forgotten wooden nail is finding its place once again, offering a beautiful alternative to metal that honors our connection to the natural world while promoting sustainable practices. Whether in a rustic cabin, a handcrafted piece of furniture, or a carefully restored historic building, wooden nails remind us of the timeless art of woodworking and the enduring importance of utilizing natural materials.

Waterproof fiber mesh is a specialized fabric made from synthetic fibers that have been engineered to repel water while maintaining breathability. This dual functionality is achieved through advanced manufacturing techniques, which often involve the incorporation of water-resistant treatments and the creation of a network of interwoven fibers. The result is a lightweight yet robust material that can withstand harsh weather conditions without compromising performance.

2. Construction In the construction industry, PVC welded wire mesh serves as reinforcement for concrete structures. It enhances durability and prevents cracking, ensuring the longevity of buildings and pavements.

Overall, fiberglass products offer a wide range of benefits and applications across various industries. Their lightweight nature, strength, durability, and cost-effectiveness make them a popular choice for a wide range of applications, from construction to marine to art and design. With advancements in technology, the use of fiberglass products is only expected to continue to grow in the coming years.

Strength and Durability

Fiberglass rods are composite materials made from a mixture of glass fibers and resin. This composite structure provides excellent strength-to-weight ratio, corrosion resistance, and flexibility. Fiberglass rods can come in various percentages of fiberglass concentration, and a 1.25% fiberglass rod denotes that the rod contains 1.25% fiberglass content relative to the total composite material. This lower concentration makes these rods particularly lightweight while still retaining essential strength characteristics.

Manufacturers implement rigorous testing protocols to ensure that each nail meets specifications for dimensions, strength, and durability Manufacturers implement rigorous testing protocols to ensure that each nail meets specifications for dimensions, strength, and durability

Manufacturers implement rigorous testing protocols to ensure that each nail meets specifications for dimensions, strength, and durability Manufacturers implement rigorous testing protocols to ensure that each nail meets specifications for dimensions, strength, and durability china corrugated roofing nails. This attention to detail is crucial for maintaining the integrity of roofing structures and protecting against leaks or failures under adverse weather conditions.

china corrugated roofing nails. This attention to detail is crucial for maintaining the integrity of roofing structures and protecting against leaks or failures under adverse weather conditions.