Conclusion

Conclusion

In summary, gas pressure reducing valves are indispensable for safe and efficient gas distribution in both residential and industrial applications. Their ability to regulate pressure not only contributes to safety but also ensures that gas-operated systems function efficiently and reliably. As technology advances, ongoing improvements in PRV design and functionality will further enhance their role in modern gas delivery systems, making them even more critical in the pursuit of safety and efficiency in gas applications. Understanding and selecting the appropriate PRV is essential for anyone involved in gas systems, ensuring compliance with safety standards and the effective operation of gas appliances and equipment.

A gas pressure regulator valve is a mechanical device that reduces and controls the pressure of gas coming from a source, such as a gas main or tank, before it reaches its intended application. The primary function of the regulator is to maintain a steady output pressure, regardless of fluctuations in the input pressure or the demands of the downstream equipment or systems.

Applications of Gas Pressure Vessels

The regasification process begins with the transfer of LNG from storage tanks to vaporization units. These units utilize different methods to heat the LNG, including ambient air, seawater, or more advanced technologies such as electric heating. As the LNG warms up, it returns to its gaseous form, which can then be distributed through pipelines for residential, industrial, and commercial use. The efficiency of this process is paramount, as any energy loss during regasification can lead to increased costs and reduced supply reliability.

Additionally, these stations also enhance the efficiency of the gas distribution system. By controlling pressure fluctuations, they ensure an uninterrupted and steady supply of gas, which is essential for heating, cooking, and powering various appliances in homes and businesses. This operational stability is crucial for maintaining consumer confidence in the gas supply system.

Pressure reduction valves are an essential component in various systems, serving to enhance safety, efficiency, and process control. As industries continue to evolve, the importance of PRVs in maintaining stable and safe operational conditions cannot be overstated. Investing in quality PRVs not only ensures compliance and safety but also contributes to the overall effectiveness and reliability of systems across multiple applications. Understanding their function, types, and applications is crucial for engineers and operators working in pressure-sensitive environments.

Types of Relief Valves

Gas safety valves play a crucial role in ensuring the safe operation of gas systems in various applications, from residential furnaces to industrial gas pipelines. These specialized valves are designed to prevent dangerous gas leaks and maintain safe working conditions, safeguarding both human life and property.

Safety Considerations

In conclusion, gas organizers play a vital role in modern society by ensuring the safe and efficient management of gases across various industries. Their significance extends beyond mere organization; they enhance safety, contribute to environmental sustainability, and improve operational efficiency. As we continue to face challenges related to safety and environmental concerns, the importance of effective gas organization will only grow, driving innovation and improvement in this essential area. Embracing advanced gas management systems will not only lead to better safety outcomes but will also foster a more sustainable and productive future.

1. Residential Home heating systems, water heaters, and gas stoves all utilize gas regulators to maintain safe and efficient operation.

Gas pressure reducers are fundamental devices used in various applications, including residential heating, industrial processes, and automotive systems. Their primary function is to decrease the high pressure of gas from a source, such as a pipeline, to a safer, regulated pressure that is suitable for end-use applications. This article provides an overview of gas pressure reducers, their importance, and the different types available on the market.

A gas pressure reducing valve is a mechanical device installed within gas distribution systems to reduce and stabilize high-pressure gas from the supply line to a lower, usable pressure suitable for consumption. As natural gas is distributed from production sites to end users, it travels through pipelines under high pressure. Directly using this high-pressure gas in appliances or industrial processes can be dangerous and inefficient. Therefore, PRVs play a vital role in ensuring that the gas delivered to households and businesses is at a safe and usable pressure level.

Safety is a paramount consideration in the design and operation of PRS. These stations are equipped with multiple safety valves and monitoring systems that ensure any irregularities are swiftly addressed. Moreover, pressure relief valves are installed to prevent over-pressurization, which can lead to catastrophic failures.

Heat exchangers for gases are used in a variety of industries, reflecting their versatility. Key applications include

At the core of a gas heat exchanger's operation is the principle of heat transfer. The design allows two or more fluids at different temperatures to exchange thermal energy without mixing. This process typically involves conduction, convection, and sometimes radiation. The primary goal is to reduce energy consumption by recovering waste heat or improving the efficiency of heating or cooling systems.

Despite their importance, pressure relief valves are not immune to challenges. Regular maintenance and testing are essential to ensure their reliability. Factors like corrosion, wear and tear, and improper sizing can hinder valve performance, potentially leading to dangerous situations. It is crucial for industries to adhere to regulatory standards and implement a proactive maintenance schedule.

Conclusion

1. Spring-Loaded Relief Valves These are the most widely used type. They operate using a spring mechanism that holds the valve closed until the pressure exceeds the set limit. Once the pressure threshold is breached, the valve opens to allow fluid to escape.

The operation of a gas pressure regulator valve can be understood through its basic components the diaphragm, spring, and two ports (inlet and outlet). When gas enters the regulator, it exerts pressure on the diaphragm. The diaphragm's movement compresses or decompresses the spring, which then adjusts the opening of the valve to either allow more gas through or restrict its flow.

Electric regulating valves are essential components in various industrial processes, playing a crucial role in the control and management of fluid flow, pressure, and temperature. These valves operate using electrical signals, allowing for precise regulation and automation in fluid handling systems. In this article, we will explore the functionality, benefits, and applications of electric regulating valves.

At its core, a gas coalescer filter employs the principle of coalescence to remove contaminants from gas. When a gas stream flows through the filter, it passes through layers of specialized media that are engineered to promote the agglomeration of fine liquid droplets suspended in the gas.

The Importance of Pressure Relief Valves

In addition to safety, gas organizers contribute to environmental sustainability. With the growing awareness of climate change and the need for responsible resource management, industries are increasingly adopting practices that minimize their environmental footprint. Gas organizers facilitate the efficient use of gases, reducing waste and emissions. By optimizing gas distribution and ensuring that gases are used only when necessary, these systems help in conserving resources and protecting the environment.

Pneumatic control valves play a crucial role in various industrial applications, serving as vital components in fluid control systems. These devices manage the flow of air and other gases through pipelines and equipment, ensuring that processes operate efficiently and safely. Understanding their function and significance is essential for industries that rely on pneumatic systems, including manufacturing, automotive, and aerospace.

1. Coalescing Filters These filters are used to remove liquid water and particulates from gas streams. They work by promoting the coalescence of fine water droplets into larger ones, which can then be easily separated from the gas.

This constant adjustment ensures that appliances receive a uniform pressure supply, which is crucial for optimal performance. If the gas pressure is too low, appliances may not function properly; if it's too high, it can lead to potential hazards, including equipment damage or accidents.

On the other hand, electronic or smart gas meters represent the latest advancements in gas metering technology. These meters not only measure gas consumption but also have the capability to transmit data wirelessly. This allows utilities to remotely monitor consumption patterns, perform diagnostics, and even detect leaks more efficiently. Smart meters enhance transparency for consumers by providing detailed insights into their consumption habits, allowing them to manage their energy use better.

- Versatility Pressure reducers come in various sizes and designs, allowing them to be used in a wide range of applications, from small laboratory setups to large industrial systems.

5. Check Valves While not a direct shutting mechanism, check valves prevent backflow in a system, ensuring that fluids flow in one direction.

The importance of gas pressure regulating valves cannot be overstated. They are essential for

- Environmental Protection Gas heat exchangers are instrumental in waste heat recovery systems, helping industries reduce emissions and energy consumption by recycling heat energy.

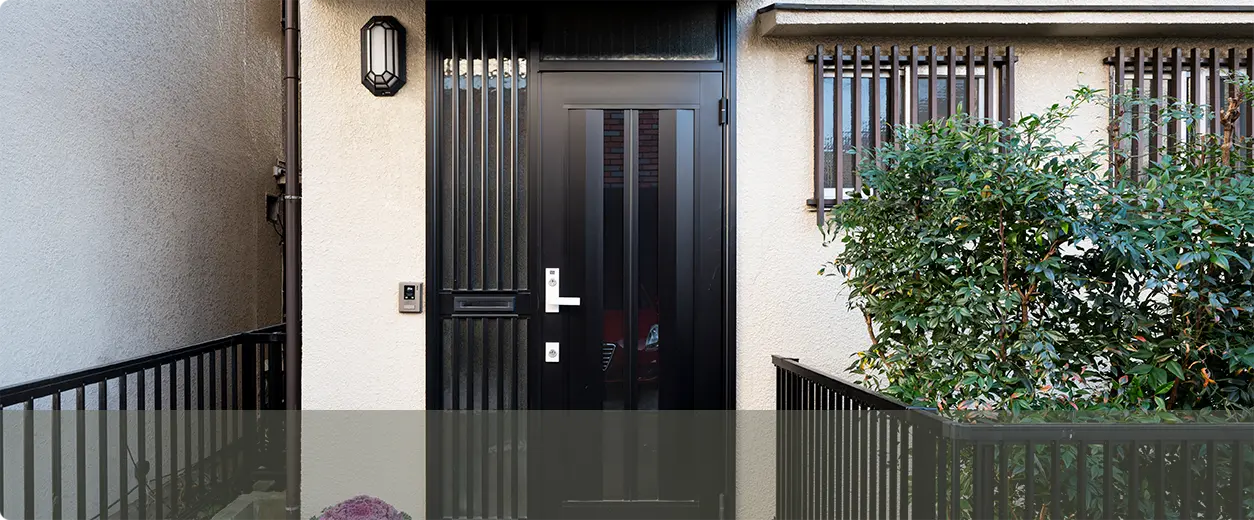

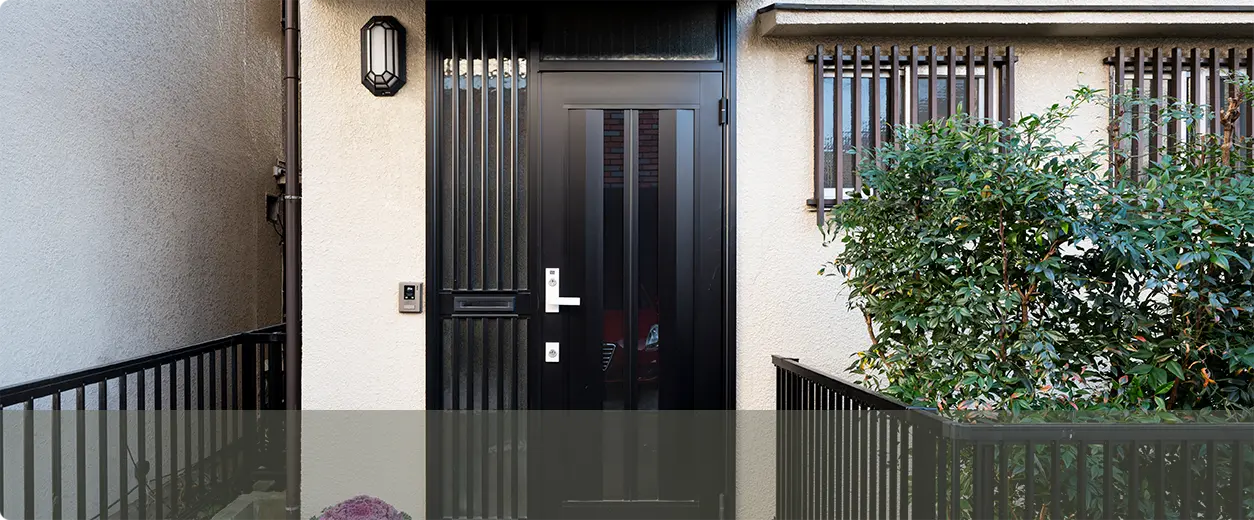

Be careful not to remove them entirely, as this could cause the assembly to fall off Be careful not to remove them entirely, as this could cause the assembly to fall off

Be careful not to remove them entirely, as this could cause the assembly to fall off Be careful not to remove them entirely, as this could cause the assembly to fall off adjusting rollers on sliding screen door.

adjusting rollers on sliding screen door.1. Enhanced Energy Efficiency One of the primary advantages of thermal break aluminium profiles is their ability to improve a building's energy efficiency. Traditional aluminium frames conduct heat, resulting in significant energy loss. However, with thermal break technology, the flow of thermal energy is restricted, leading to a more stable indoor temperature.

Here are the steps to follow

Here are the steps to followThe aesthetic appeal of real spears cannot be understated. Many are adorned with intricate carvings or paintings, showcasing the artistry of their creators. These embellishments often tell stories—some depict ancestral figures, while others symbolize natural elements such as animals and plants. As a result, real spears become more than mere weapons; they become pieces of art that reflect the values and beliefs of the cultures that produced them.

Moreover, aluminium profiles can be customized to incorporate thermal breaks, which enhance energy efficiency by reducing heat transfer between the interior and exterior of a building. This feature helps in maintaining comfortable indoor temperatures and reducing energy consumption for heating and cooling.

Before replacing the rollers, it is recommended to clean the window tracks and rollers to remove any dirt or debris that may be causing the issue. This can be done using a damp cloth or a mild cleaning solution. Once the tracks and rollers are clean, it is time to remove the old rollers.

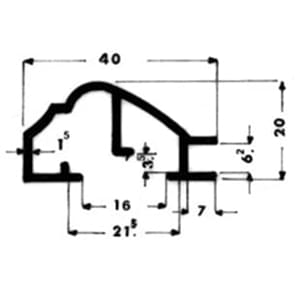

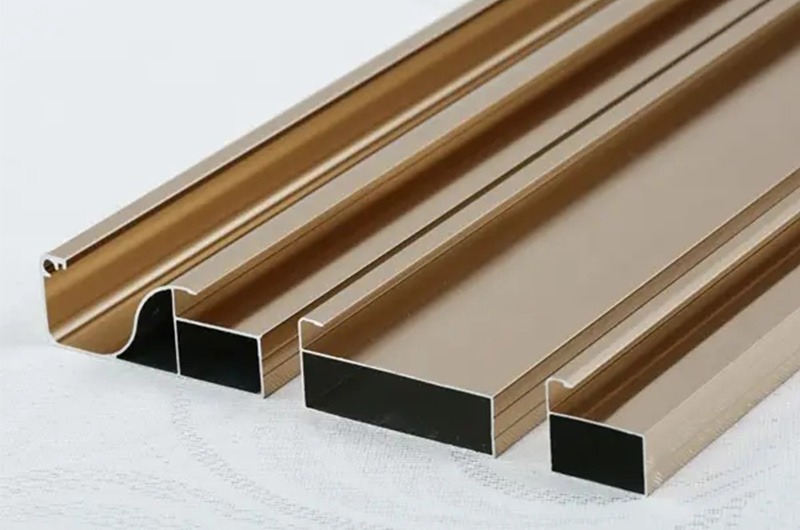

Aluminum Profile for Window

These boxes can be used to store a wide range of items, from gardening tools and sports equipment to camping gear and holiday decorations These boxes can be used to store a wide range of items, from gardening tools and sports equipment to camping gear and holiday decorations

These boxes can be used to store a wide range of items, from gardening tools and sports equipment to camping gear and holiday decorations These boxes can be used to store a wide range of items, from gardening tools and sports equipment to camping gear and holiday decorations outdoor metal storage box with lock. Their compact design makes them easy to transport and store, allowing you to keep your belongings organized and easily accessible when needed.

outdoor metal storage box with lock. Their compact design makes them easy to transport and store, allowing you to keep your belongings organized and easily accessible when needed.Historical Context

Most importantly, set the right price. Pricing should reflect the artistic potential of the wrought iron. Research what similar items are going for in your area and online. Remember, unique or antique pieces can often fetch a higher price. Be open to negotiation, as many artists and crafters work within tight budgets.

The bottom line here is that modern aluminium profiles are absolutely no worse insulated than wooden or, even more so, plastic ones. On the contrary, modern aluminium window profiles are distinguished by the best thermal performance and are often used in the construction of passive houses. As a result, the price of aluminium windows and doors has risen considerably in recent years, and we currently have to pay more for them than for wooden windows!

4. Adjustable Wheels Some sliding door wheels are designed with adjustability features, allowing for height modifications to ensure optimal alignment with tracks. This is crucial for maintaining a smooth operation over time.

Inspect the seals and weatherstripping around your aluminum windows: Regularly inspect the seals and weatherstripping around your aluminum windows for any signs of wear, damage, or gaps. Replace damaged or worn-out seals to maintain proper insulation and energy efficiency. Clean the seals regularly to prevent dirt or debris buildup that can affect their effectiveness.

Thermal break profiles with polyamide strips are therefore a logical choice. They not only contribute to your living comfort, but also to your health (condensation and mould have no chance). And last but not least, they again help prevent demands on your purse every month because of soaring energy costs.

Slatwall can typically be found in commercial establishments, particularly retail stores. These objects are usually a composition of different aluminum profiles that are stacked atop one another to form a pallet-looking wall.

Additionally, they can be fabricated to accommodate various window styles, from casement to sliding, providing homeowners and designers with a broad range of choices Additionally, they can be fabricated to accommodate various window styles, from casement to sliding, providing homeowners and designers with a broad range of choices

Additionally, they can be fabricated to accommodate various window styles, from casement to sliding, providing homeowners and designers with a broad range of choices Additionally, they can be fabricated to accommodate various window styles, from casement to sliding, providing homeowners and designers with a broad range of choices aluminum window extrusion profiles.

aluminum window extrusion profiles. Aluminum is a highly conductive material that helps to regulate temperature within a building, reducing the need for artificial heating and cooling Aluminum is a highly conductive material that helps to regulate temperature within a building, reducing the need for artificial heating and cooling

Aluminum is a highly conductive material that helps to regulate temperature within a building, reducing the need for artificial heating and cooling Aluminum is a highly conductive material that helps to regulate temperature within a building, reducing the need for artificial heating and cooling aluminum profiles for doors and windows. This can result in significant cost savings on electricity bills and also contribute to a more sustainable environment.

aluminum profiles for doors and windows. This can result in significant cost savings on electricity bills and also contribute to a more sustainable environment.Anodizing

Anodizing cannot peel off. The coating is part of the metal. Anodizing gives aluminum a deeper, richer metallic appearance than is possible with organic coatings. This is because an anodized coating is translucent, and one can see the base metal underneath the coating. Anodizing provides a thin aluminum oxide layer, which will deteriorate over time. Depending on the thickness and quality of the anodization, the surface should last 10-20 years.

The versatility of stainless steel boxes with locks is another compelling reason to consider them. They are not limited to a specific use; instead, they can serve various purposes across different contexts. In office environments, these boxes can securely store confidential files, protecting sensitive information from prying eyes. For individuals, they can serve as safes for important documents, jewelry, cash, or heirlooms. Additionally, in industrial settings, stainless steel boxes can safeguard tools and equipment, ensuring that everything is organized and protected against theft or damage.

In addition to their custom fabrication services, Orion Ornamental Iron Inc. also offers a wide selection of pre-designed iron products that can be customized to fit the specific needs of each client. From traditional to contemporary designs, their extensive product line includes a variety of options to enhance the beauty and functionality of any property.