3. Rupture discs These are non-reclosing devices that burst at a set pressure, releasing gas or liquid. They are often used in conjunction with other relief valve types for added safety.

صمام التنفيس

Accurate gas metering is crucial not only for billing purposes but also for safety. Gas leaks can pose serious risks to life and property. Regular monitoring and reporting through gas metering systems help identify abnormal consumption patterns that may indicate a leak or other issues. Utility companies often implement monitoring systems that provide alerts for unusual consumption changes, allowing for prompt investigation and resolution.

The Importance of Natural Gas in Modern Energy Solutions

Gas Filtration An Essential Process in Environmental Management

A gas booster primarily functions to increase the pressure of gas flowing through pipelines. This is crucial in various applications, including natural gas distribution, such as ensuring that gas reaches homes and businesses at adequate pressure for heating and cooking. Boosters are also critical in industrial settings, where high-pressure gas is necessary for processes like power generation and manufacturing.

The primary function of a gas pressure reducing valve is to decrease and stabilize the pressure of a gas entering a system. When gas flows from a high-pressure source, such as a gas main, to a lower-pressure distribution system, the PRV adjusts the pressure to a predetermined level suitable for the downstream equipment. The valve operates on the principle of a diaphragm mechanism, where changes in downstream pressure result in adjustments to the valve opening, maintaining the desired output pressure.

At its core, a gas regulator is a mechanical device designed to control the pressure and flow of gas from a storage source to a consumer appliance. Most commonly used in residential setups for appliances like gas stoves, water heaters, and furnaces, gas regulators are also vital in industrial settings for processes requiring controlled gas supply.

- Oil and Gas Electric valves play a critical role in the oil and gas sector, managing the flow of crude oil, natural gas, and refined products.

3. High-Pressure Reducers Designed for high-pressure systems, they are built to withstand extreme conditions while steadily regulating pressure.

Benefits of Electric Auxiliary Heaters

Additionally, some stations incorporate safety mechanisms such as excess flow valves, which can close off gas supply if the flow rate exceeds a predetermined limit, as a response to pipe ruptures or major leaks. This feature is crucial for minimizing the risk of explosions and other dangerous incidents.

Electric Water Heaters An Overview

- Pressure Regulation Maintaining appropriate pressure is vital for the effective operation of gas appliances. Valves help regulate and stabilize pressure levels throughout the distribution system.

Pressure relief valves (PRVs) are vital components in various industrial applications, especially in systems where pressure control is crucial for safety and operational efficiency. These devices are designed to protect equipment and personnel from the hazards associated with excessive pressure, which can lead to catastrophic failures. This article delves into the importance, functionality, and applications of pressure relief valves, as well as their role in maintaining safety standards.

Despite these challenges, LPG remains a critical component of the global energy mix. Its adaptability and efficiency provide a bridge towards more sustainable energy sources while addressing immediate energy needs. Governments and organizations are increasingly recognizing the potential of LPG to facilitate a smoother transition to renewable energy sources by serving as a reliable backup during the shift.

Choosing the Right Air Control Valve

Additionally, gas distribution stations often include odorization units that add a distinctive smell to natural gas, making it easier to detect leaks. This safety measure is crucial, as natural gas is colorless and odorless in its pure form. Regular maintenance and monitoring of gas distribution stations are vital to prevent leaks, which can lead to dangerous situations and significant economic losses.

Environmental Considerations

Types of Measurement Systems

A pressure regulating skid is a pre-packaged assembly designed to control and regulate fluid pressure within piping systems. Typically, these skids include various critical components such as pressure regulators, valves, gauges, and piping—all mounted on a sturdy framework for easy integration into any system. The primary function of the skid is to maintain the desired pressure levels, thereby preventing potential damage to equipment, avoiding hazardous situations, and ensuring efficient operation.

Regulating valves, often referred to as control valves, are designed to adjust the flow rate of a fluid based on the feedback from a control signal. The controlling element of the valve responds to changes in system pressure, temperature, or flow rate, allowing for precise flow management. These valves can be modulated using various mechanisms, including pneumatic, electric, or hydraulic actuators, providing flexibility in operation and integration into automated systems.

Gas pressure regulating valves come in several types, each designed for specific applications and pressure ranges. The most common types include

2. Flow Control Valves These valves maintain a desired flow rate of compressed air. They are important for applications where the speed of an actuator needs to be controlled without affecting the overall pressure in the system.

The Role of Natural Gas Pressure Regulators in Safe and Efficient Energy Distribution

The primary function of a gas safety relief valve is to maintain safe pressure levels within a system

. When the pressure rises above the set limit, the valve opens, allowing gas to escape until the pressure drops back to a safe level. This process happens quickly and automatically, preventing potential disasters such as explosions or system ruptures.Understanding Gas Pressure Vessels Importance and Applications

However, to maximize the efficacy of pneumatic control valves, proper selection and maintenance are paramount. Several factors must be considered, including the type of application, the nature of the media being controlled, and the specific environmental conditions. Regular maintenance, including cleaning and inspection, is also essential to prevent issues such as leaks or blockages, which can significantly impact system performance.

gas metering. Accurate metering in these sectors is essential for managing costs and ensuring that operations run smoothly. By accurately measuring gas usage, companies can identify areas where energy efficiency can be improved and ultimately reduce their overall consumption.

gas metering. Accurate metering in these sectors is essential for managing costs and ensuring that operations run smoothly. By accurately measuring gas usage, companies can identify areas where energy efficiency can be improved and ultimately reduce their overall consumption.1. Portable Gas Cylinders These are typically small and used for a variety of applications, such as welding, medical oxygen, and camping. They are lightweight and designed for easy transport.

- Enhanced Efficiency By effectively removing particulates and moisture, these filters improve the efficiency of downstream equipment, such as compressors and turbines. This leads to reduced energy consumption and operational costs.

Gas regulators can be classified into several categories based on their intended application

The success of supercharger technology has sparked interest among other automotive manufacturers as well. Companies like Ford, Volkswagen, and General Motors are now investing in their own fast-charging infrastructure, recognizing that a robust charging network is essential for the widespread adoption of electric vehicles. Collaborations and partnerships between automakers and charging networks are becoming increasingly common, signaling that the industry understands the importance of making EVs accessible and convenient for all drivers.

Moreover, pressure regulators are also critical in laboratory settings where precise pressure is necessary for experimental processes

. They ensure that the conditions remain stable, allowing for accurate and reliable results.4. Pest Prevention

3. Sound Dampening The density and elasticity of EPDM contribute to its ability to absorb sound, making it an effective solution for noise reduction in industrial settings or residential areas.

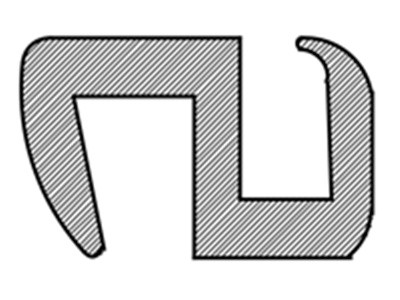

Understanding Edge Trim Seal Strips An Essential Component for Various Applications

Next, thoroughly clean the door frame and remove any existing weatherstripping or adhesive residue. This will ensure a secure bond when installing the new weatherstripping. Use a mild detergent and water to clean the surface, and allow it to dry completely before proceeding.

Another advantage of weather seals is their ability to minimize noise pollution. In busy urban environments, noise from traffic, construction, and other sources can seep into buildings through unsealed doors. Weather seals effectively block these noise waves, creating a quieter and more peaceful indoor environment. This is beneficial not only for residential properties but also for offices, hospitals, and educational institutions, where a conducive atmosphere is essential for productivity and well-being.

Selecting the Right Mechanical Seal

The versatility of 1-inch foam tape extends to its applications in various environments, including residential, commercial, and industrial settings. In construction, it is invaluable for weatherproofing, soundproofing, and vibration dampening. In manufacturing, it can be used for assembly tasks and as part of product packaging to prevent damage during shipping. The craft and hobbyist communities also leverage foam tape for projects ranging from scrapbook design to model building, demonstrating its broad appeal and utility.

1. Enhanced Safety One of the primary reasons for using glass edge protector seals is safety. Sharp edges of glass can pose significant hazards, especially in commercial spaces frequented by large groups of people. Protector seals help mitigate these risks by creating rounded, softer edges that are less likely to cause injury.

2. Enhanced Comfort Drafts can cause discomfort, making certain areas of a home colder than others. By sealing off these gaps, windproof sealing strips contribute to a more uniform temperature throughout the house, resulting in improved comfort for occupants.

Benefits of Using Foam Expansion Strips

Regularly check your weather stripping for signs of wear and tear. Replace any damaged sections promptly to maintain an effective barrier against air leaks. Cleaning the weather stripping occasionally can also help prolong its life.

Advantages of Dry Mechanical Seals

Mechanical seals are critical components in various rotating equipment, ensuring that fluids do not leak between stationary and rotating parts. Among the various types of mechanical seals, the Type 2021 is widely used due to its reliability and effectiveness in different applications. This article will delve into the dimensions and design considerations of the Type 2021 mechanical seal, which can be crucial for engineers and maintenance professionals working with pumps, compressors, and other machinery.

Energy Efficiency

One of the primary reasons car manufacturers include door molding is its aesthetic appeal. Molding comes in various designs, colors, and finishes, allowing vehicle owners to customize the appearance of their cars. Whether you prefer a sleek and modern look or something more rugged and robust, there is a door molding option to suit every style. Additionally, car door moldings can create a seamless look that ties together various design elements of the vehicle, enhancing the car's visual flow and sophistication.

What are Mechanical Seals?

In conclusion, flexible rubber edge trim is more than just a simple accessory; it is a multifunctional solution that offers protection, enhances aesthetics, ensures safety, and provides durability across various applications. As industries evolve and the demand for quality and safety heightens, the importance of such versatile products will undoubtedly continue to grow. Embracing innovations like flexible rubber edge trim can lead to improved design outcomes and greater consumer satisfaction, making it a valuable asset in any production line.

2. V-Strips Made of metal or plastic, V-strips are flexible and can be attached to the door frame. They work well for smaller gaps and are durable over time.

The Importance of Rubber Weather Seal Tape in Home Maintenance

First, you need to identify the areas where air leakage is most prominent First, you need to identify the areas where air leakage is most prominent

First, you need to identify the areas where air leakage is most prominent First, you need to identify the areas where air leakage is most prominent weather stripping for around doors. This can be done by holding a lit candle or a feather near the door edges; if the flame flickers or the feather moves, air is passing through. Once identified, measure the areas to be sealed and purchase the appropriate weatherstripping material. Following the manufacturer's instructions, apply the weatherstrip to the door frame, ensuring a snug fit.

weather stripping for around doors. This can be done by holding a lit candle or a feather near the door edges; if the flame flickers or the feather moves, air is passing through. Once identified, measure the areas to be sealed and purchase the appropriate weatherstripping material. Following the manufacturer's instructions, apply the weatherstrip to the door frame, ensuring a snug fit.4. Non-Pusher Seals These seals rely on the inherent design and materials for maintaining contact, often suitable for steady state pressure applications.

Installation and Maintenance

Energy Efficiency

The Importance of Bottom Door Frame Seals Enhancing Home Efficiency and Comfort

At its core, car door seal trim serves a simple yet essential purpose it prevents water, dust, and noise from entering the vehicle. This is accomplished through a specially designed rubber or foam material that creates a tight barrier between the door and the car’s body. The presence of effective door seals ensures that the interior of the car remains clean and free from undesirable elements. For example, rainwater can seep into the vehicle through small gaps, leading to potential damage to the interior and the risk of mold development. Good seal trim minimizes these risks significantly.

One of the primary functions of door molding is to safeguard the car's bodywork. The edges of car doors can be vulnerable to dings and scratches, especially in crowded parking lots where close encounters with other vehicles are frequent. Door molding serves as a barrier, absorbing impacts that could otherwise result in costly repairs. This protective measure not only helps maintain the vehicle's aesthetic appeal but also contributes to its resale value. Cars with minimal body damage tend to retain their market value better than those with noticeable dents and scratches.

3. Temperature Regulation A well-sealed vehicle can maintain its internal temperature more effectively. Car door window strips prevent warm or cool air from escaping, making your air conditioning or heating system more efficient. This can lead to less fuel consumption and a more comfortable environment for passengers.

Conclusion

Common Types of Door Seals

4. Bumper Seal Strips These are used in front and rear bumpers to provide a buffer against minor impacts and to seal gaps that might otherwise allow water and dirt into the vehicle’s structure.

1. Protection from Physical Damage One of the primary functions of door trim protectors is to shield the sensitive surfaces of car doors from dents and scratches caused by accidental bumps in parking lots, careless movements during entry or exit, or even minor collisions. The protectors act as a barrier, absorbing impact and protecting the underlying door trim.

5. Versatile Options Foam insulation strips are available in various sizes and thicknesses, making them suitable for different types of windows. Whether you have single-pane or double-pane windows, there is a foam strip that will fit your needs.

In addition to thermal stability, silicone foam seals are highly resistant to weathering, UV radiation, and ozone. This makes them an excellent choice for outdoor applications where seals are exposed to harsh environmental conditions. For instance, in the construction industry, silicone foam seals are utilized in window frames and door seals to enhance energy efficiency by preventing air and moisture infiltration. Their ability to maintain performance over time under exposure to sunlight and varying weather conditions ensures that buildings remain airtight and insulated.

- Easy Installation T type rubber seals are easy to install in their designated grooves, making them a preferred choice for many applications.

Foam tape is typically made from a compressible foam material that is coated with a strong adhesive on one or both sides. Available in various thicknesses, densities, and adhesive types, foam tape provides excellent cushioning and insulation properties. It is resistant to moisture, chemicals, and extreme weather conditions, making it a durable choice for both indoor and outdoor uses.

Conclusion

4. Seal the Finish Once the paint has fully dried, apply a high-quality sealant. Water-based polyurethane is a common choice for kitchen cabinets due to its durability and non-yellowing properties. Apply at least two coats, allowing adequate drying time between applications.

In today’s fast-paced industrial world, the need for reliable and efficient adhesive solutions is more critical than ever. One such solution that has gained traction across various sectors is the 1% thick foam tape. This versatile product combines unique properties of foam with adhesive backing, making it a go-to choice for numerous applications, from construction and manufacturing to arts and crafts.

1. Water Protection One of the most vital roles of window strips is to protect the interior of your car from water damage. Rain, snow, and even car washes can lead to moisture seeping into the cabin if the seals are worn out. This moisture can contribute to mold growth and damage interior components, which can be costly to repair.

Types of Mechanical Seals Used in Pumps

Proper maintenance of mechanical seals is critical for the longevity and efficient operation of booster pumps. Regular inspection should focus on several key areas

What Are External Door Rubber Seals?