Understanding Gas Coalescer Filters

Understanding Gas Coalescer Filters

In conclusion, understanding and implementing effective business organization is vital for any company aiming for long-term success. By establishing clear structures, promoting open communication, and remaining adaptable, businesses can enhance their efficiency and resilience in an ever-changing marketplace.

1. Relief Valves These are designed to open and relieve pressure when it exceeds a set limit, allowing gas to escape safely. Once normal pressure is restored, the valve closes automatically.

Natural Gas Filtration Ensuring Clean Energy Supply

- Medical Facilities In hospitals, medical gas pressure reducers ensure that oxygen and other gases are delivered at the correct pressures for patient care.

natural gas pressure regulator. These guidelines ensure that the regulator is compatible with the existing system and is installed in locations that are easily accessible for maintenance and inspection purposes. It's also essential to choose a regulator with the appropriate capacity to handle the required gas flow rate for the particular application.

natural gas pressure regulator. These guidelines ensure that the regulator is compatible with the existing system and is installed in locations that are easily accessible for maintenance and inspection purposes. It's also essential to choose a regulator with the appropriate capacity to handle the required gas flow rate for the particular application.

Additionally, in an increasingly digital age, where social media and technology often blur the lines of truth, the concept of Al-Muthabit serves as a reminder to remain vigilant in our quest for knowledge. The prevalence of false narratives can be overwhelming, but by grounding ourselves in rigorous standards of verification and critical thinking, we can uphold the principles of Al-Muthabit.

2. Efficiency Gas pressure reducers contribute to the efficiency of gas systems. By ensuring that the gas is delivered at the appropriate pressure, they enhance the performance of equipment such as burners, engines, and industrial machinery.

The Precision Voltage Regulator An Essential Component in Modern Electronics

In summary, gas pressure regulating valves are integral components in various applications across multiple industries. They not only ensure the safe and efficient delivery of gas but also protect equipment and personnel from the dangers associated with improper pressure levels. As industries continue to evolve and expand, the role of these valves will remain crucial, cementing their position as a backbone of safe gas utilization. Proper maintenance and timely replacements of these valves can lead to increased safety, energy efficiency, and operational reliability.

Applications of Gas Boosters

Understanding Safety Relief Valves Importance and Functionality

Conclusion

The materials used in constructing gas pressure vessels must ensure durability, strength, and resistance to extreme temperatures and corrosive substances. Steel, for example, is commonly used due to its high tensile strength, while coatings or linings are often applied to protect against specific chemicals.

The breather valve is also used in equipment such as pressure vessels, heat exchangers, and reactors. In these applications, the breather valve plays a critical role in protecting the equipment and ensuring safe operation. By releasing excess pressure or vacuum, the breather valve helps to prevent catastrophic failures and accidents.

Understanding Pressure Regulating Valves Importance and Applications

What are Safety Relief Valves?

Functions and Importance

In addition to mattresses, seat cushions and supportive chairs play a crucial role in pressure relief during sitting. Much like their bed counterparts, these cushions are engineered to distribute weight evenly and provide comfort. Some designs incorporate gel or foam materials that conform to the body’s shape, reducing pressure on critical areas like the tailbone and thighs. These products are particularly beneficial for individuals who spend long hours seated, such as office workers and those who use wheelchairs.

3. Energy Sector In the energy sector, gas pressure regulators are used in the transportation and distribution of natural gas. They help maintain the pressure required for safe delivery to homes and businesses, playing a vital role in energy supply systems.

Moreover, in an era where environmental considerations are becoming increasingly important, filter separators can help natural gas companies meet regulatory requirements. By ensuring that the gas is clean and free of harmful substances, companies can minimize their environmental impact and adhere to local and international standards.

The rise of e-commerce has further transformed the role of distribution stations. With the growing demand for fast shipping and same-day delivery, distribution stations have had to adapt quickly to meet these expectations. Many have implemented strategies such as strategic location selection, where facilities are situated closer to major population centers to shorten delivery times. Moreover, the integration of technology plays a significant role in enhancing speed and accuracy, with companies investing in smart warehousing solutions that leverage AI, machine learning, and Internet of Things (IoT) technologies.

Filter separators play a vital role in maintaining the integrity and efficiency of natural gas processing systems. By removing undesirable substances, they help to prevent pipeline blockages, equipment damage, and operational disruptions. In addition to preserving the safety of pipeline systems, these devices also contribute to environmental protection by ensuring that any released liquids are managed appropriately.

Moreover, regular testing and inspection of safety valves are critical for maintaining safety standards in industrial operations. Many organizations adhere to specific guidelines and regulations, such as those outlined by the American Society of Mechanical Engineers (ASME), which set forth standards for the design, manufacturing, and testing of safety valves. By conducting routine checks and maintenance, industries can ensure that their safety systems are effective and compliant with safety regulations.

Syngas produced from gasification is versatile and can be used in various applications. One of the most notable uses is in power generation; syngas can be utilized in gas turbines or internal combustion engines to produce electricity. Additionally, syngas serves as a precursor for producing synthetic fuels, such as methanol or hydrogen, which have significant potential in reducing our dependence on fossil fuels.

The Importance of Decompression Skids in Modern Industry

4. Demand Management As energy demand fluctuates throughout the day and across seasons, GPRS can adjust the pressure of gas being delivered to meet consumer needs. This flexibility enables energy suppliers to respond dynamically to changes in demand, optimizing the overall efficiency of the energy supply system.

Understanding Regulating Valves An Essential Component in Fluid Control Systems

Benefits of Using Pressure Regulating Devices

2. Diaphragm Movement The high-pressure gas pushes against the diaphragm within the regulator. This diaphragm is a flexible membrane that responds to increasing pressure.

Conclusion

The filtration process begins at the extraction site, where gas is produced from underground deposits. During extraction, various contaminants can enter the gas stream. The first step in filtering natural gas typically involves the removal of larger impurities, such as dirt and debris, using coarse filters. After these initial filtration steps, fine filtration processes come into play. These may include various techniques such as adsorption, membrane separation, and chemical treatment to eliminate smaller particulates and harmful gases.

Applications of Pressure Reducing Valves

Despite their importance, distribution stations face several challenges. The increasing complexity of global supply chains, fluctuating consumer demands, and geopolitical uncertainties can disrupt the flow of goods. Additionally, the ongoing digital transformation in logistics requires continuous investment in technology and workforce training. Operators must be agile and adaptive to overcome these challenges while maintaining service quality and efficiency.

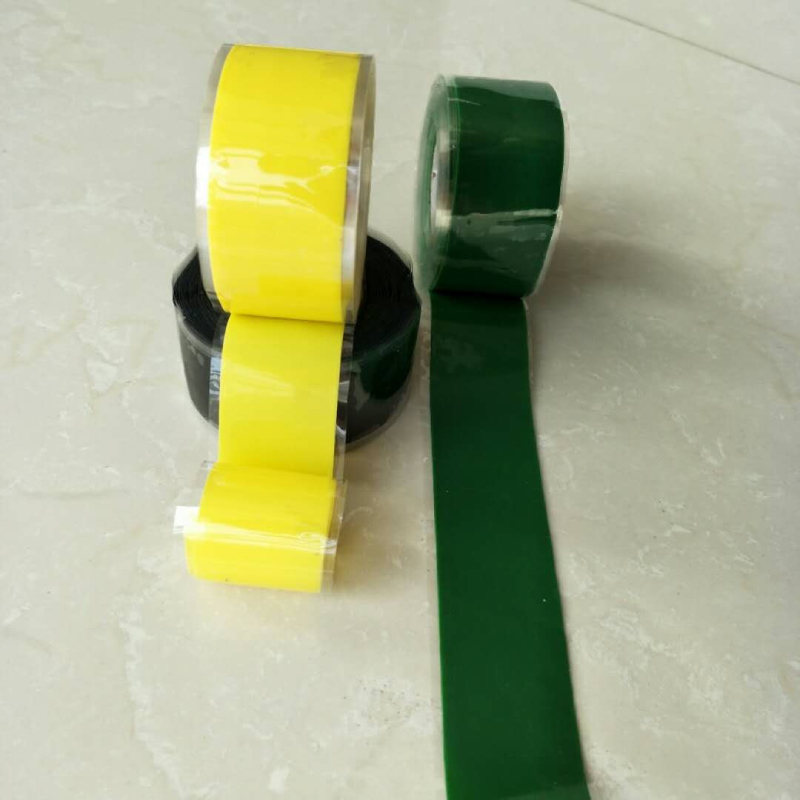

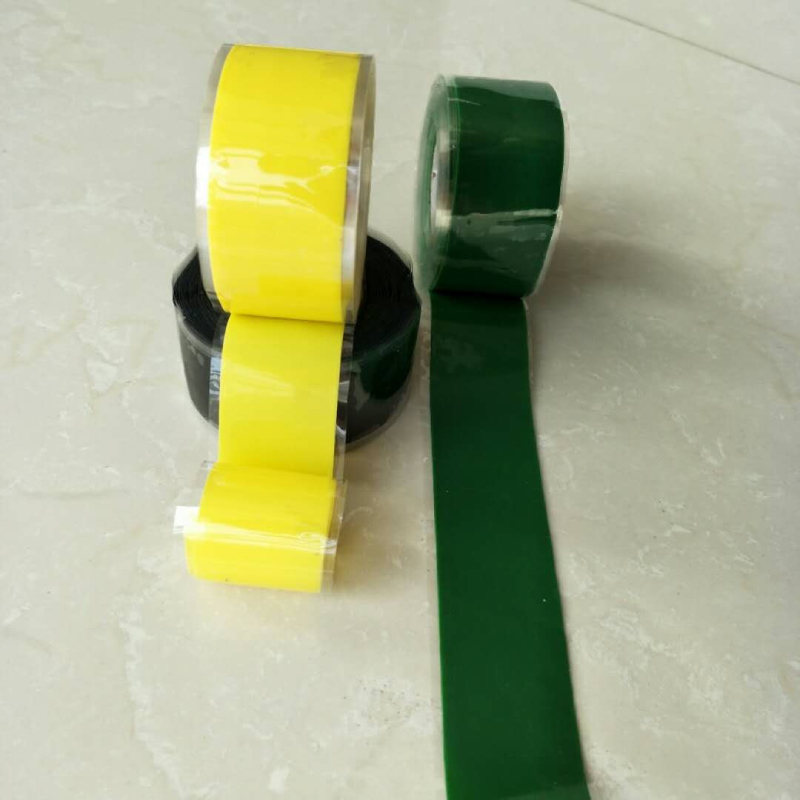

PVC, or polyvinyl chloride, is a commonly used material in the electrical industry for its excellent insulation properties. PVC can be found in various electrical applications, such as wires, cables, and electrical tape. PVC electrical insulation is known for its durability, flexibility, and cost-effectiveness, making it a popular choice for many industries.

One of the key advantages of using 130C linerless rubber splicing tape is its ability to provide a tight and secure seal. This makes it perfect for applications where a leak-proof bond is essential, such as in plumbing or automotive industries. The tape is also resistant to chemicals and oils, further enhancing its durability and reliability.

It can be customized with different colors, patterns, or even company logos, adding a touch of style to the otherwise industrial-looking engine compartment It can be customized with different colors, patterns, or even company logos, adding a touch of style to the otherwise industrial-looking engine compartment

It can be customized with different colors, patterns, or even company logos, adding a touch of style to the otherwise industrial-looking engine compartment It can be customized with different colors, patterns, or even company logos, adding a touch of style to the otherwise industrial-looking engine compartment wire harness automotive cloth tape.

wire harness automotive cloth tape.In conclusion, floor marking tape is an important tool for creating safe, organized workspaces in a variety of environments. When considering the price of floor marking tape, be sure to prioritize quality, durability, and adhesive strength to ensure that you are getting the best value for your money. By carefully comparing prices and considering your specific needs, you can find the right floor marking tape at a price that fits your budget.

Strong, pliable, elastic and versatile

An industrial control box is not just an accessory; it’s a critical component in a well-oiled industrial environment, facilitating uninterrupted operations and enhancing safety.

4. Cost-Effective Solution Investing in premium butyl rubber tape is an economical choice. Compared to extensive repair work or replacing damaged materials, using butyl rubber tape to seal leaks can extend the life of existing structures. Regular maintenance with this tape can help prevent the occurrence of severe problems, leading to substantial savings in the long run.